Why Reflective Paint for Metal Matters to Procurement Buyers

For industrial buyers sourcing metal cabinets, HVAC ducting, or utility enclosures for extreme conditions, the paint system is not just a surface finish—it’s a performance tool. Reflective coatings reduce surface temperatures by 15–30°C depending on the coating type and substrate—whether galvanized, anodized aluminum, or pre-coated. This minimizes thermal expansion cycles and maintains structural integrity. Reflective coatings help reduce HVAC load, extend repaint intervals, and meet compliance targets—without structural redesign.

Reflectivity Explained: Key Performance Metrics Buyers Should Know

Reflective coatings perform based on two measurable factors:

Solar Reflectance (SR): Percentage of sunlight reflected.

Thermal Emittance (TE): Ability to shed absorbed heat.

These combine to form the Solar Reflectance Index (SRI)—a standard metric in material specs for roofs, enclosures, and solar-adjacent structures. High-SRI coatings (e.g., SRI > 100) can help reduce internal cabinet temperatures by up to 26°C.

Pigment selection is critical. IR-reflective oxides like titanium dioxide or borosilicate ceramics offer optimal reflectivity without chalking or fading. For anodized aluminum paint systems, a pre-treatment layer—such as aluminum wood primer or chromate conversion—is mandatory for adhesion. This is especially important when applying spray paint over powder coated metal, or when upgrading legacy enclosures.

Unlike generic white finishes, engineered high-SRI coatings with optimized pigments ensure measurable field performance.

Choosing Between Paint and Powder: System Compatibility for Bulk Orders

Understanding how paint and powder coating interact is critical for bulk projects. Procurement teams must balance cost, cure cycle, durability, and service environment.

Water-Based Acrylics & Solvent-Free Fluoropolymers

These low-VOC solutions are ideal for buyers concerned with compliance and environmental impact. Used on telecom shelters and outdoor kiosks, they offer fast curing and good IR reflectivity. HVLP spray guns yield uniform finishes and minimize overspray.

Powder Coat Over Paint or Bare Metal

Powder coating offers excellent mechanical durability, UV resistance, and color stability. It’s the preferred method for galvanized steel enclosures, marine panels, and modular energy equipment. Buyers often specify dual-layer systems—primer + top coat powder coating—for added chemical resistance.

When applying powder coating over existing paint, ensure surface compatibility and test for adhesion (e.g., ASTM D3359). Powder coating standards for metal enclosures usually define DFT, cure temperature, and corrosion cycles.

Epoxies and Ceramic-Enhanced Coatings

For harsh industrial zones near lathing machines or chemical plants, epoxy coatings resist solvents and abrasion. Ceramic additives boost thermal performance and UV resistance—crucial in solar frame infrastructure or automated warehousing.

Matching Coating Strategy to Field Applications

Paint choice should align with real-world stressors. The table below supports spec writing:

| Use Case | Substrate | Challenge | Coating Recommendation |

|---|---|---|---|

| Solar frame | Anodized aluminum | UV, conductivity | Ceramic top coat + conversion primer |

| Trailer top | Galvanized steel | Heat cycling | Epoxy primer + high-SRI finish coat |

| Utility housing | Painted steel | Humidity, voltage | Fluoropolymer over epoxy primer |

Each setup requires checking compatibility with legacy finishes and confirming flash-off or cure protocols. Buyers specifying reflective coating for OEM energy equipment must ensure alignment with both substrate and field operating temperature ranges.

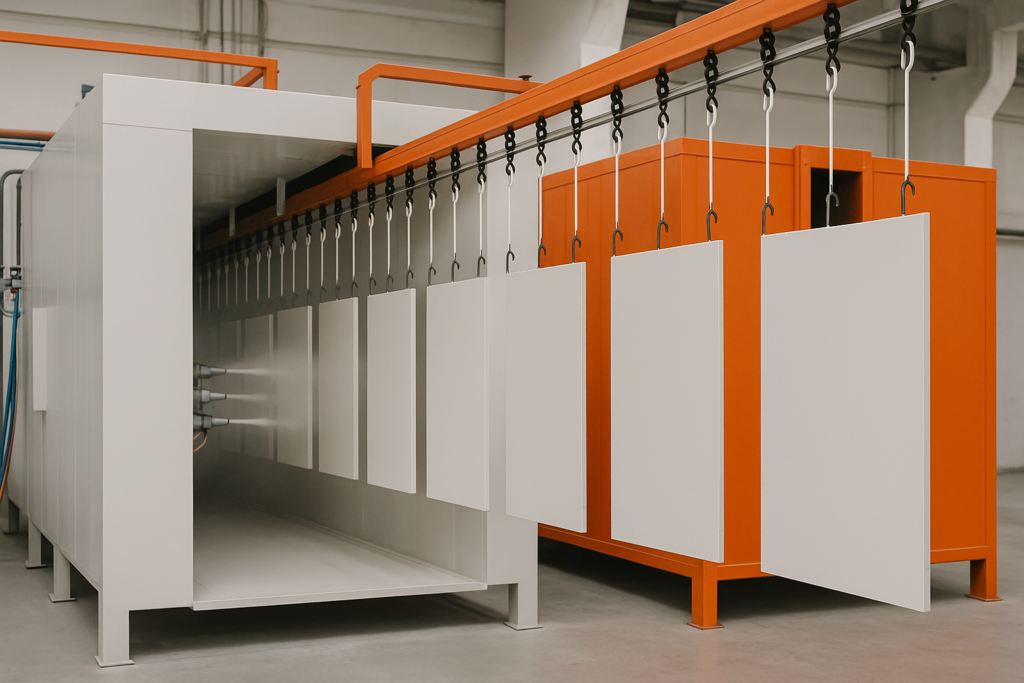

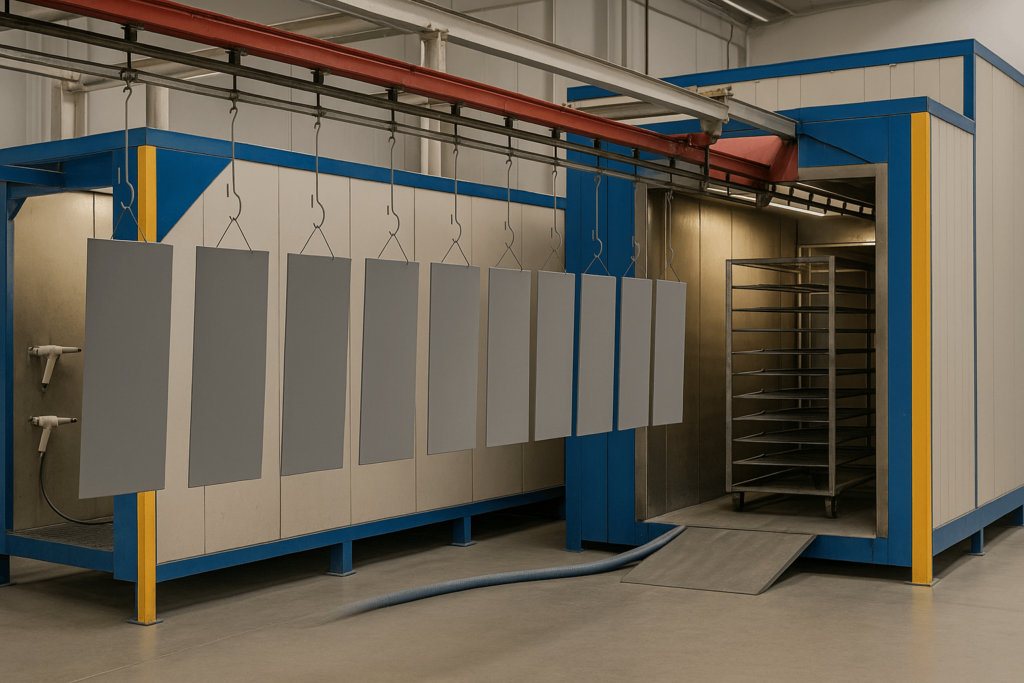

Application Integrity: Ensuring Vendor Process Control

A high-spec paint is only as good as its application. Buyers should confirm vendors follow strict standards:

📋 Application QA Checklist for Batches:

Surface Prep & Cure: SSPC-SP 10 (near-white blast) or ISO 8501-1 Sa 2.5 followed by cure confirmation (oven profile or ambient humidity control).

Coating Thickness: Powder 60–100μm, liquid 40–70μm DFT.

Adhesion Validation: Cross-hatch test per ASTM D3359.

Documentation: Batch traceability and QC logs for OEM scalability.

YISHANG’s automated lines ensure coating consistency across volume runs. Bulk coating for metal fabrication requires repeatability and traceability—a key concern for OEMs and resellers.

Field-Proven Results: Using Data to Drive RFQ Criteria

Buyers should leverage existing case data:

Port Logistics (GCC): Switching to SRI 105 ceramic coating cut wall temps by 26.5°C.

EV Charging Cabinets (SEA): Reflective systems improved inverter runtime, reduced fan use by 17%.

Cold Chain Trucks: Top coat powder coating over anodized surfaces reduced HVAC runtime by 22%.

Modular Rooftop Enclosures (Germany): Partnered with an industrial reflective paint supplier to meet DIN EN ISO 11607 and regional fire codes.

These metrics strengthen purchase justifications. When submitting RFQs, reference similar use cases with expected IR savings or reduced repaint intervals. This helps clarify how to specify industrial powder coating system parameters.

Maintenance & Lifecycle ROI Considerations

Reflective coatings often last over a decade, but upkeep is crucial. Buyers should request lifecycle expectations and compatible maintenance schedules.

Inspection Benchmarks:

| Timeframe | Inspection Focus | Test Standard |

| Year 1–3 | Gloss Retention | ASTM D523 |

| Year 5–7 | Chalking/Fading | ASTM D4214 |

| Year 10+ | Adhesion Integrity | ISO 4628-8 |

Lifecycle Coating Cost Comparison (10 Years):

| Coating Type | Recoat Frequency | Maintenance Cost Estimate |

| Standard Paint | 2–3 recoats | $8–12/m²/year |

| High-SRI Paint | 1–2 recoats | $5–7/m²/year |

| Powder + Ceramic Top Coat | 1 recoat or less | $3–5/m²/year |

Downtime Cost Impact: Lower-maintenance coatings reduce planned vs unplanned production interruptions, particularly in automated environments. This improves total cost of ownership and maintains OEM warranty timelines.

For coastal or high-sulfur regions, a dual system resists oxidation better. Sourcing touch-up kits aligned with the original coating system maintains warranty and system integrity. Include corrosion resistant reflective paint system in your specification for such environments.

Regulatory Alignment & Performance Trends

Procurement strategies increasingly align with both compliance and efficiency targets:

LEED Credits: High-SRI coatings aid building certification.

ESG Criteria: Powder coatings with low embodied energy score better.

Adaptive Coatings: Reduce HVAC peaks and internal heat load.

Example: A data center operator in UAE reduced HVAC draw by 18% after upgrading to adaptive high-SRI powder coating systems on rooftop ducting.

Relevant compliance references include UL 1332 for coated electrical enclosures and REACH regulations for chemical content limits in imported goods. YISHANG supports procurement with spec sheets, test data, and compatibility declarations. For buyers requiring anodized aluminum paint or best paint for galvanized metal roofs, our catalog includes validated options.

Final Take: Reflective Paint Is a Strategic Choice

Reflective systems extend lifespan, reduce internal heat, and avoid early rework—critical outcomes for procurement teams managing complex installations.

YISHANG offers engineered solutions tailored to batch size, finish spec, and operational conditions. Whether your project needs spray paint over powder coated metal or powder coating systems for telecom enclosures—we support your industrial finishing strategy with proven system compatibility.

Have a project spec? Contact YISHANG to align with coating strategies proven in industrial use.