Misunderstood but Ubiquitous: Why Buyers Rely on Schedule 40 Pipe

For many international B2B procurement professionals, what is Schedule 40 pipe often becomes a critical question during sourcing. At first glance, it appears to be a universal solution, but real-world usage reveals that it’s not always one-size-fits-all. Choosing it without understanding the material or usage environment can result in costly delays, returns, or—even worse—system failures.

YISHANG once supported a European OEM in agricultural automation. They sourced Schedule 40 PVC for irrigation lines. Within three months, cracks developed due to high ambient heat and overlooked pressure derating. These costly surprises highlight the importance of detailed spec validation during procurement.

Let’s now unpack the real meaning behind Schedule 40 pipe, its best applications, and what professionals must consider before finalizing a purchase order.

What Schedule 40 Really Means: A Dimensional, Not Functional, Standard

Schedule 40—defined under ASME B36.10M (for carbon steel) and B36.19M (for stainless steel)—refers specifically to wall thickness in relation to Nominal Pipe Size (NPS). It does not determine pressure class, corrosion resistance, or temperature tolerance.

For instance, a 2″ NPS pipe has a fixed outside diameter (OD) of 2.375 inches. What varies is its inner diameter and mechanical strength. Compared to Schedule 80, Schedule 40 is easier to fabricate and manipulate in tube laser cutting and other downstream operations.

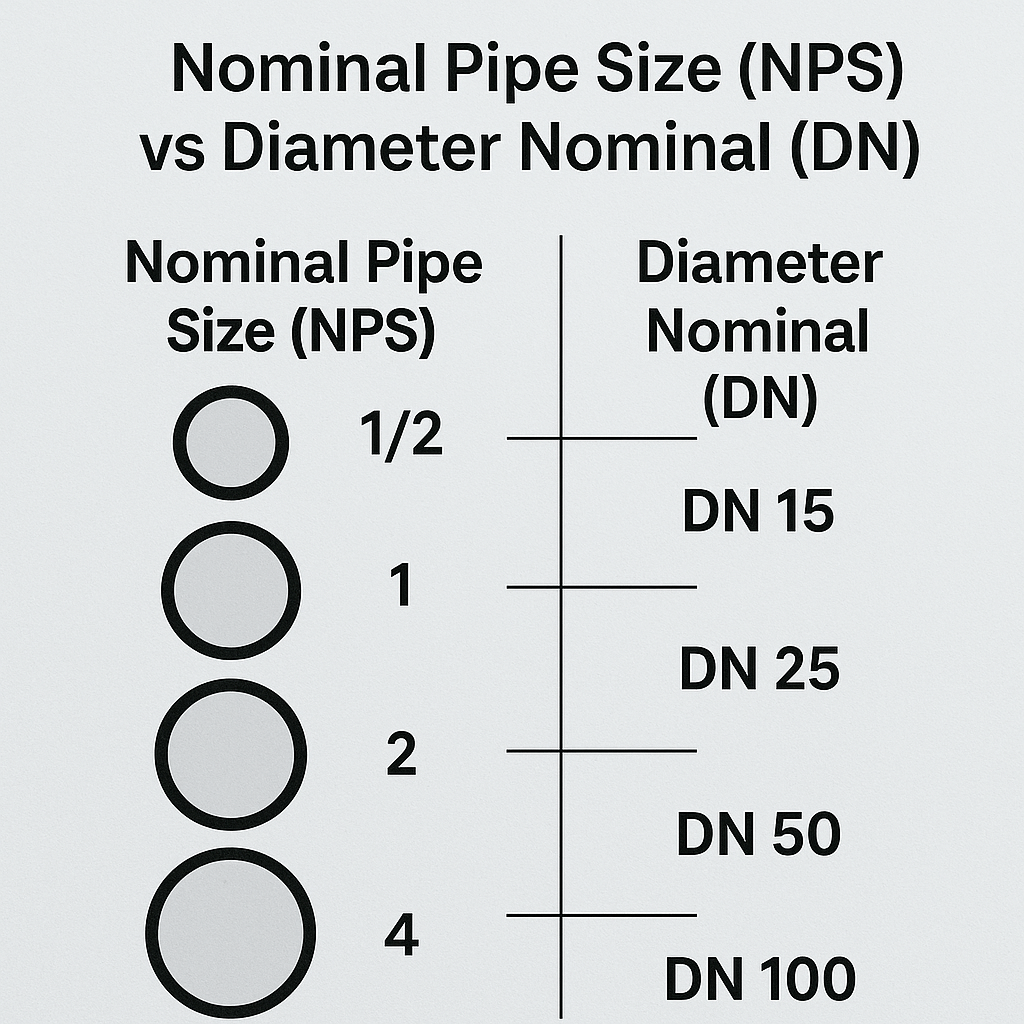

International procurement teams working in mixed-unit environments should also align NPS with DN (diameter nominal) values. Here’s a quick reference:

| NPS (in) | DN (mm) |

|---|---|

| 1″ | DN25 |

| 2″ | DN50 |

| 4″ | DN100 |

| 6″ | DN150 |

| 12″ | DN300 |

This matters during cross-border RFQs, especially when components interface with metric tube fittings, aluminum extrusion tube assemblies, or undergo precision laser tube cutting.

Schedule 40 also aligns well with common fabrication needs—whether bending stainless steel pipe, bending rectangular tubing, or working with laser cut tube forms in alloy and carbon steel.

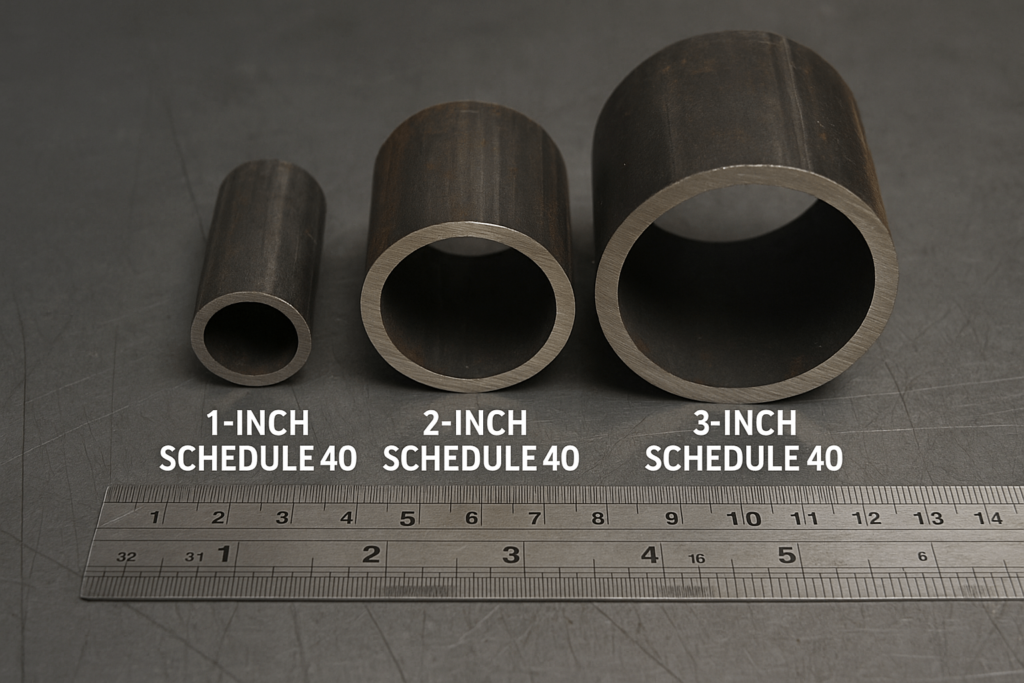

Specification Table: Common Dimensions of Schedule 40 Pipe

| NPS | Outside Diameter (in) | Wall Thickness (in) | Weight (lbs/ft, Steel) |

| 1″ | 1.315 | 0.133 | 1.68 |

| 2″ | 2.375 | 0.154 | 3.66 |

| 4″ | 4.5 | 0.237 | 10.79 |

| 6″ | 6.625 | 0.280 | 18.97 |

| 12″ | 12.75 | 0.375 | 53.50 |

These figures inform transportation loads, bending specs, and fabrication compatibility. Schedule 40 balances strength and cost and supports consistent processing in laser cutting and moderate-pressure systems.

Schedule 40 by Material: Performance Differences Buyers Must Know

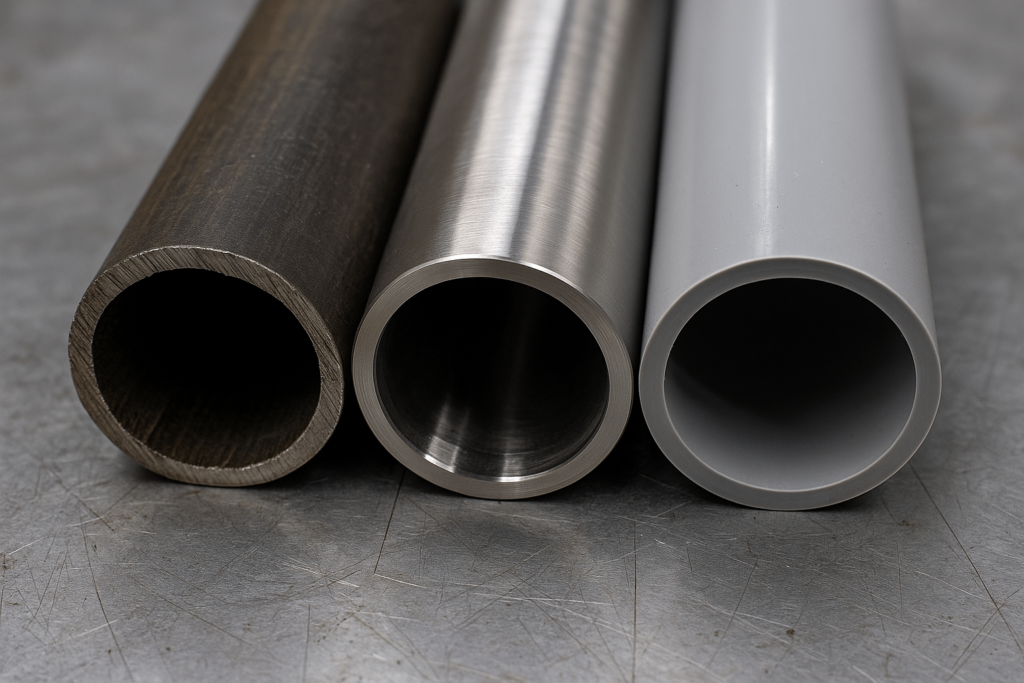

Carbon & Galvanized Steel (ASTM A53/A106)

Commonly used in industrial fluid systems for their structural integrity, weldability, and reliable pressure ratings. Galvanized options offer corrosion resistance, though not suitable for high-temperature or sanitary applications. Seamless carbon steel pairs well with pipe nipples and tube laser services.

Stainless Steel (ASTM A312 / 304 / 316)

Ideal for food-grade, marine, and corrosive environments. Frequently used in precision structures, pressure piping, and chrome plating exhaust pipes. Excellent compatibility with laser cutting of tubes and cold-forming for bent stainless tubing needs.

PVC / CPVC (ASTM D1785 / D2846)

Economical for ambient, low-pressure fluid systems. But thermal derating is significant:

2″ PVC: 280 PSI @ 73°F

~100 PSI @ 140°F

For hot water, compressed air, or outdoor installations, stainless tubing or Schedule 80 alternatives offer better long-term reliability.

Schedule 40: Best Use Cases Across Industries

Commercial & Infrastructure Projects

Used in plumbing, sleeves, conduit, and utility pathways. Buyers value compatibility with pipe union vs coupling assemblies, and straightforward handling with laser-based fabrication or bending tooling.

Manufacturing & Utilities

Employed in air systems, secondary chemical loops, and non-critical fluid networks. Adaptable to tube laser cutting or mild forming. For tight-radius or high-tolerance needs, Schedule 80 or reinforced materials are advised.

Agricultural OEM & Irrigation Systems

Schedule 40 PVC is common in pressure-controlled irrigation, though heat, UV, and joint fatigue require material validation. In rugged conditions, alternatives like Schedule 80, bending steel tubing, or stainless tubing are often more durable.

When Schedule 40 Isn’t Enough: Recognizing the Application Threshold

Schedule 40 isn’t inherently rated for every condition. Two risk domains often overlooked:

Temperature & Pressure Compatibility

Thermal derating impacts both steel and plastic variants. For example, a 3in stainless steel pipe loses significant pressure tolerance beyond 400°F.

Where corrosive fluids or high temperature coexist, Schedule 80 or custom-thickness alloys become critical—not optional. These also fare better during cold-forming or fatigue-cycle loads.

Structural Stress & Vibration Fatigue

Long unsupported spans or pump-induced vibration can trigger stress fractures. Best practices include use of reinforced stainless steel tubing, simulation testing, and validated bend machine shop practices when complex forming is required.

Specifying It Right: How to Communicate Schedule 40 in RFQs

Avoid vague specs. Writing “2-inch Schedule 40 pipe” omits crucial sourcing parameters.

Better:

2″ NPS, Schedule 40, ASTM A106 Gr B, seamless, beveled ends, black oil finish, 6-meter length, RoHS compliant

Also clarify:

Media, operating temp & pressure

Plating or finish needs

Tolerance (for tube laser cutting or post-forming)

Certifications (ISO, RoHS, MTC)

Preferred packaging (bundle, pallet, capped)

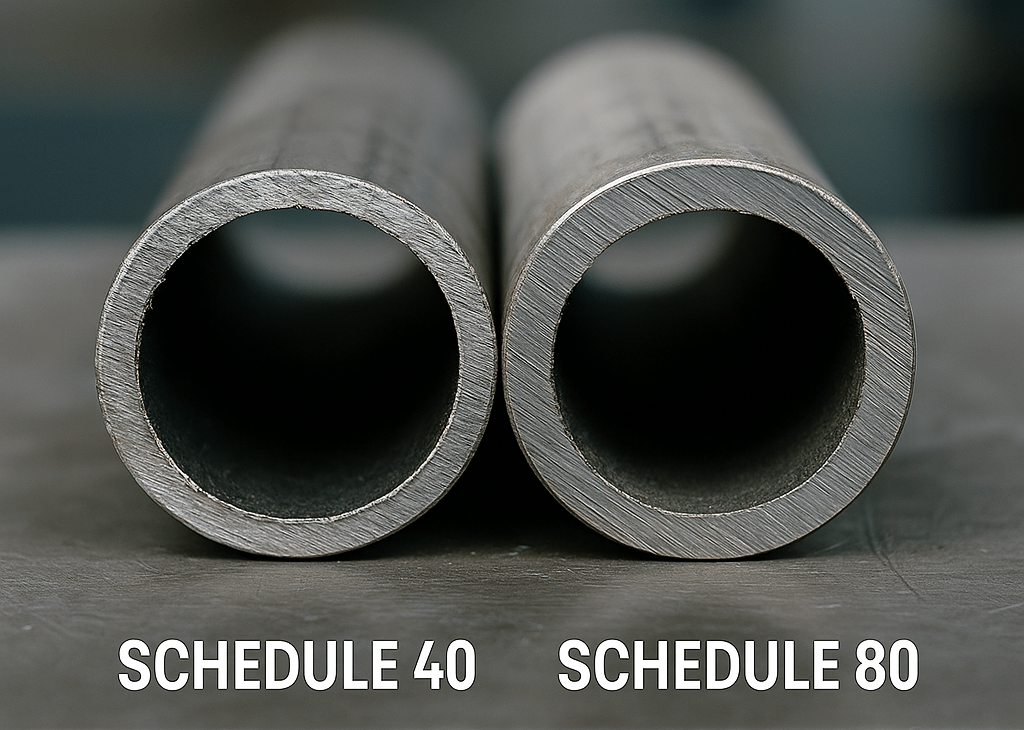

Don’t Default—Decide: Schedule 40 vs Schedule 80

Buyers often default to Schedule 40 for cost or familiarity—but wrong specification increases lifecycle cost and failure risk.

Schedule 80 features thicker walls, making it better suited for:

High-pressure loops

Corrosive or elevated-temp fluids

Complex bending / forming tasks

Alternatively, projects involving precision or aesthetic post-processing (e.g. chroming exhaust pipes) may demand customized wall thickness or alloy grades beyond standardized schedules.

Final Word: Contextual Specification Wins Deals, Not Standard Copy-Paste

Schedule 40 is a standardized profile—but application performance varies greatly by environment, fluid, and processing. The right vendor doesn’t just stock it—they help you specify the correct variant based on volume, spec, and service temperature.

YISHANG provides verified Schedule 40 options across stainless, carbon steel, aluminum, and even custom laser tube cutting integrations.

➡️ Request your project-specific quote today—faster delivery starts with smarter specifications.