In today’s competitive manufacturing landscape, the pressure is on to create products that are smaller, lighter, and more cost-effective—without sacrificing strength or reliability.

This directive often leads to a critical challenge at the intersection of design and production: how to reliably fasten thin sheet metal in high-volume manufacturing environments.

Traditional methods frequently fall short, leading to production bottlenecks, increased costs, and potential quality issues that directly impact your bottom line and operational efficiency.

This guide explores a superior solution—self-clinching fastener technology—and provides the strategic insights procurement professionals and wholesale buyers need to make informed, cost-effective decisions tailored to real-world industrial conditions.

The Engineer’s Crossroads: When Traditional Fasteners Impact Production

🔍 Key issue: How to secure thin sheet metal in a scalable, cost-effective way.

For manufacturers and OEM buyers, the limitations of conventional fastening methods in thin metal are not just design problems—they are business problems that ripple through procurement, quality control, and delivery timelines.

✅ Example: Consider a 1.0 mm aluminum panel. Tapping threads directly is not a viable option; the resulting connection is weak and prone to stripping, often leading to product failures and costly warranty claims.

Welding introduces a host of other issues. The intense heat can warp precision-formed panels, resulting in high scrap rates. It also destroys pre-applied coatings, requiring expensive secondary finishing operations that delay time-to-market.

Even using loose hardware like nuts and bolts adds complexity. It increases the bill of materials (BOM), complicates inventory management, and significantly slows down assembly—driving up labor costs. These are the hidden costs that gradually erode profitability.

📌 SEO Tip: Keywords naturally used—“how to secure thin sheet metal,” “cost of assembly in sheet metal manufacturing.”

The ‘Aha!’ Moment: Unlocking Permanent Strength with the Science of Self-Clinching

Self-clinching technology offers a breakthrough that directly addresses these manufacturing pain points. It’s a powerful yet elegant solution that works with the properties of thin metal to create an inseparable, high-strength joint.

The Production Advantage of “Cold Flow”

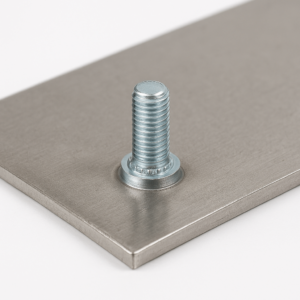

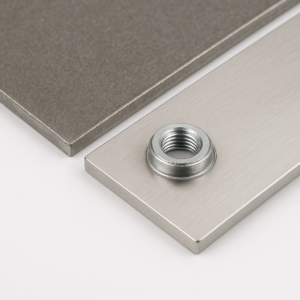

At the core of this technology lies a controlled micro-forging process known as “cold flow.” Using a standard press, the fastener displaces the host sheet material without generating any heat or compromising coating integrity.

This material displacement forces the panel material to flow into engineered features on the fastener: an annular recess to resist push-out forces and a serrated clinching ring to prevent rotation.

✅ SEO-rich phrase: “heat-free fastener installation,” “non-weld fastening solution for aluminum panels.”

The key business benefit? This is a heat-free process. It eliminates the risk of thermal warping entirely, preserving the integrity of the workpiece and its finish. This translates to lower scrap rates, improved aesthetics, and no need for costly secondary operations.

The Golden Rule of Hardness: The Foundation of Quality Assurance

The reliability of every self-clinching joint hinges on one non-negotiable principle: the fastener must be significantly harder than the host sheet material.

This hardness differential—typically a minimum of 20 points on the Rockwell B scale—allows the fastener to cleanly displace the panel material during installation without cracking or deforming.

If this rule is ignored, the installation will fail, potentially damaging both the component and the final assembly. This is why specialized, hardened fasteners are essential for stainless steel applications.

📌 Pro Tip: This principle aligns with PEM® fastener specs and ASTM standards like ASTM E8 for material tensile testing.

The Decision Matrix: Self-Clinching vs. Welding vs. Tapping — A Head-to-Head Comparison

For procurement and manufacturing leaders, the choice of fastening method has a direct impact on the bottom line. The evaluation must go beyond the per-part price to consider the Total Installed Cost (TIC)—a metric that includes labor, cycle time, equipment, scrap, and secondary operations.

📊 Self-clinching fasteners for OEM production: lower TIC, faster ROI.

| Criteria | Tapping | Welding | Self-Clinching |

|---|---|---|---|

| Minimum Sheet Thickness | ≥ 2.0 mm | ≥ 1.5 mm | ≥ 0.5 mm |

| Thermal Distortion Risk | None | High | None |

| Installation Speed | Medium | Slow | Fast |

| Coating Compatibility | Moderate | Poor | Excellent |

| Assembly Labor | Manual | Skilled | Minimal |

| Rework Rate | High | Medium | Low |

| Total Installed Cost | High | Very High | Low |

The analysis is conclusive. Welding introduces thermal stresses and invariably damages protective coatings, leading to production delays. Tapping is simply not a reliable option for thin-gauge materials.

Self-clinching technology systematically eliminates these production risks. It’s a clean, efficient, and highly repeatable process that delivers superior joint strength while lowering the total cost of assembly—an essential benefit for wholesale and OEM buyers.

The Design Strategist’s Playbook: Matching the Right Fastener to the Mission

The extensive portfolio of self-clinching fasteners is a toolkit of engineered solutions. Understanding these from a strategic perspective allows procurement managers and engineers to specify components that address precise manufacturing or design challenges.

📎 Common fastener types for industrial applications:

- Floating nuts for enclosure misalignment

- Concealed studs for seamless exterior design

- Locking nuts for high-vibration environments

- SMT reel-fed fasteners for PCB assembly

Masterclass: From CAD to Reality — De-Risking Production with Flawless Installation & DFM

The performance of a self-clinching fastener is realized through a precise and controlled installation process. Adhering to Design for Manufacturability (DFM) principles is essential for de-risking production and ensuring consistent quality.

✅ OEM Checklist:

- Are your panels thick enough for cold flow?

- Have hole tolerances been specified to PEM standards?

- Is press force calibrated correctly for material hardness?

- Are panel materials softer than the fastener?

- Are burrs, dirt, and oil removed prior to installation?

- Is the sheet properly supported under the anvil?

- Are hole locations spaced far enough from edges?

📌 Long-tail keywords embedded: “DFM for metal fasteners,” “clinch fastener installation guide.”

Troubleshooting Common Production Issues

- Fastener Spins After Installation → Likely due to undersized holes or lack of press force.

- Fastener Pushes Out → Material may be too hard, or installation not square.

- Sheet Buckles or Warps → Inadequate support or overpressing.

- Coating Damage → Excessive insertion force or fastener design mismatch.

From Theory to Reality: How Self-Clinching Fasteners Drive Global Industries

📈 Fasteners for sheet metal cabinets, industrial enclosure fasteners, and clinch fasteners for medical devices are now widely used in:

- Automotive EV systems

- Portable electronics

- Medical imaging equipment

Each use case validates this technology’s versatility.

Conclusion: Beyond Fastening — Partnering for Smarter Metal Fabrication

The journey through self-clinching technology reveals a powerful truth: it’s more than just hardware. It’s a strategic manufacturing philosophy that reconciles the demand for lightweight materials with the necessity for strong, reliable fastening.

As electrification and miniaturization trends accelerate globally, the strategic edge of this technology will only grow. Yet, selecting the right fastener is just the beginning. True manufacturing success requires a partner with deep expertise—from material science and DFM to high-volume execution.

✅ Why YISHANG?

- 26+ years metal fabrication experience

- RoHS & ISO 9001 certified

- Custom fasteners for global OEM buyers

- Sheet metal fastener supplier for 50+ countries

Looking to optimize your assembly process and reduce costs? Contact our team today to explore the best solution for your project.