CNC Machining Service

At YISHANG, CNC machining is the cornerstone of our metalworking services. With over 26 years of experience, we provide high-quality, precise machining solutions for both prototyping and large-scale production. Our commitment to delivering accuracy and reliability ensures that your projects meet the highest standards.

What is CNC machining?

CNC machining involves the use of computer-controlled machines to shape and cut various materials, including metals, plastics, and wood.In sheet metal manufacturing, CNC machines are often used to cut, drill, and shape materials into precise components.

Unlike traditional manual methods, CNC machining allows for exact replication of designs, resulting in high-quality parts that meet tight tolerances.One of the biggest advantages of CNC machining is its ability to produce parts quickly and accurately. Once a design is programmed into the machine, it can run continuously, producing identical parts with minimal error.

This is crucial for businesses needing mass production while maintaining strict quality standards.

Our CNC Machining Process

1. Design Validation

Every project begins with a detailed review of your design files. We utilize advanced CAD/CAM software to analyze and optimize designs, ensuring they are machine-ready and aligned with your specific tolerances and material requirements. This allows us to mitigate potential issues early in the process.

2. High-Precision Machining

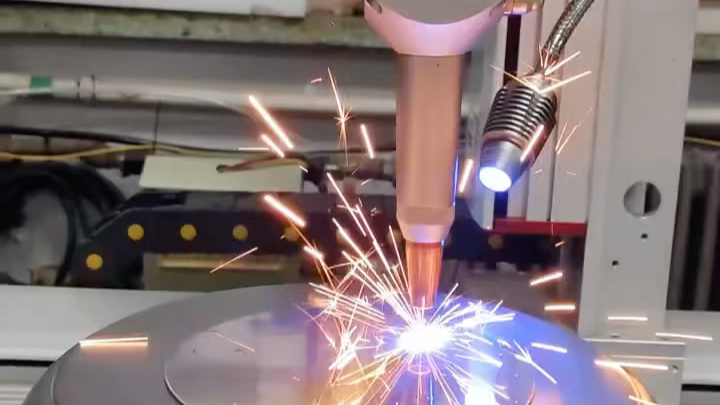

Once the design is validated, we utilize our precision CNC equipment to begin machining. With multi-axis capabilities and high-accuracy tooling, we can perform a variety of operations including milling, turning, drilling, and threading, to create complex shapes with tight tolerances and high-quality surface finishes.

3. Quality Control & Inspection

Throughout the machining process, every part undergoes rigorous quality control to ensure it meets the exact specifications. We use advanced measuring tools and techniques, such as CMM (Coordinate Measuring Machines), to verify dimensional accuracy and ensure high-quality standards.

4. Fast Turnaround and Scalability

Our highly efficient CNC machining process allows us to produce both low and high-volume runs quickly. Whether it’s a small batch of prototypes or a large-scale production order, YISHANG ensures timely delivery with the same level of precision and quality for each part.

What Materials Can Be Processed By CNC Machines?

CNC machining works with a wide range of materials, making it highly versatile for various industries. Here are the key material categories:

Metals

- Aluminum: Lightweight and strong, ideal for aerospace and automotive.

- Magnesium: 33% lighter than aluminum, used for electronic housings.

- Titanium: Very strong, commonly used in aerospace and military.

- Cast Iron: Fast machining, good for heavy machinery.

Metal Alloys

- Stainless Steel: Corrosion-resistant, used in medical and construction.

- Carbon Steel: Strong and cost-effective, widely used in automotive.

- Brass: Soft, corrosion-resistant, used in valves and fittings.

Plastics

- Nylon: Strong, flexible, used to replace metal parts.

- ABS: Common for prototypes and injection molding.

- Acrylic (PMMA): Transparent, used as a glass alternative.

- PEEK: High-performance, used in aerospace and medical.

Wood

- Soft and easy to machine, commonly used in furniture and custom wood products.

Why Choose YISHANG for CNC Machining?

Unmatched Precision

YISHANG employs state-of-the-art CNC machines, including multi-axis CNC systems, that deliver the highest level of precision for even the most complex parts. With tight tolerances, precise cutting, and excellent surface finishes, our CNC machining services meet the most demanding specifications.

Tailored Solutions for Complex Requirements

Our CNC machining services are fully customizable, offering flexibility for a range of materials and part designs. From intricate components with fine details to large-scale machined parts, we can accommodate a variety of technical requirements to ensure your parts meet both functional and aesthetic specifications.

Efficient Production with Consistency

Leveraging advanced CNC technology, YISHANG ensures fast processing times and minimal setup changes, providing quick turnarounds without compromising quality. Our experienced machinists and engineers maintain strict adherence to quality standards to ensure each part is manufactured to specification, with consistent results in both small batches and high-volume runs.

Conclusion

CNC machining is a powerful tool in the sheet metal industry, combining precision, efficiency, and flexibility. Its ability to produce high-quality parts quickly makes it an essential process in today’s manufacturing landscape.

Whether you’re looking to produce a single prototype or mass-produce thousands of components, CNC machining offers the accuracy and reliability you need.