Precision CNC Punching Service

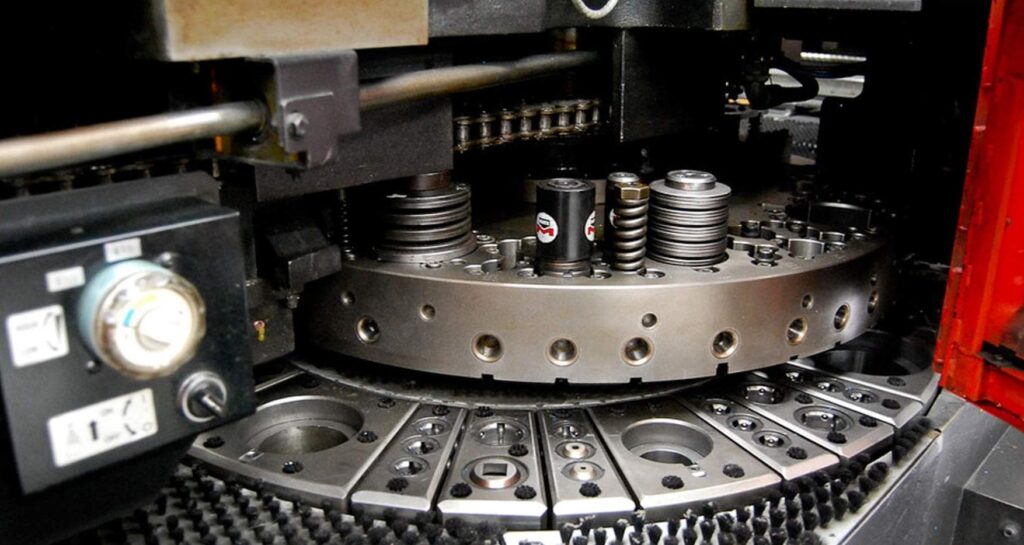

What is CNC Punching?

CNC (Computer Numerical Control) punching is a precise and efficient manufacturing process used to create holes, shapes, and designs in various metals. This process is crucial for producing parts for industries such as automotive, electronics, construction, medical equipment, and more. By using a punching machine controlled by a computer program, CNC punching ensures accuracy and repeatability for even the most complex designs.

CNC Punching Applications

CNC punching is widely used in industries where precision and efficiency are critical. Some common applications include:

Custom Panels

CNC punching is ideal for creating custom panels with specific hole patterns, slots, and cutouts.Perforated Metal

For applications requiring perforated metal sheets, CNC punching can achieve highly detailed hole patterns and consistent spacing.Brackets and Mounts

CNC punching is commonly used to produce brackets, mounting plates, and other structural components that require both precision and strength.Enclosures and Housings

The process is widely used to produce enclosures and housings for electrical devices and machinery, ensuring functional and protective designs.

The CNC Punching Process

1. Design Evaluation and Optimization

Our process starts with a detailed review of your design. Our engineering team evaluates the geometry, material, and tolerances to optimize the design for manufacturability, reducing material waste and enhancing production efficiency.

2. Material Selection

Once the design is confirmed, we carefully select the material based on the part’s specifications, ensuring that it is suitable for the punching process. We prioritize material strength, formability, and durability to ensure the finished product meets the necessary performance criteria.

3. CNC Programming

Using advanced CAD/CAM software, we convert your design into machine-readable instructions. This step ensures that every punch is executed to exact specifications, optimizing the process for maximum efficiency and minimal error.

4. Precision Punching

Our CNC punching machines perform the punching operation with high precision. From simple perforations to intricate hole patterns, we execute the design with consistent accuracy across all parts.

5. Rigorous Quality Control

Each part undergoes strict quality inspections to ensure that it meets all specifications. We measure critical dimensions and perform surface quality checks using precision instruments to verify that every part is within tolerance.

The Benefits of CNC Punching with YISHANG

Exceptional Precision and Accuracy

Our CNC punching services are designed to produce parts with tight tolerances and precise dimensions. Whether you require simple holes or intricate patterns, our machines deliver consistent, high-quality results, minimizing defects and rework.

Custom Solutions for Complex Designs

We work with a variety of materials, including stainless steel, aluminum, and copper, to create customized components. From simple to highly complex shapes, each part is crafted to meet your exact specifications with no compromises on quality.

Optimized for Cost-Effective Production

CNC punching is a highly efficient process that minimizes material waste, ensuring cost-effective production. With high-speed machines and rapid setup times, we offer competitive pricing for both small-batch prototyping and large-volume manufacturing runs.

Scalable for High-Volume Orders

Our CNC punching services are fully scalable for both prototype development and large-scale production. Whether the order is small or large, we maintain consistent quality and high throughput, ensuring timely completion of your project.

Contact Us

For inquiries or to discuss your CNC punching requirements, please feel free to contact our team. We look forward to partnering with you and providing the best sheet metal solutions for your project.