Deep Drawing Service

YISHANG provides advanced deep drawing metal fabrication services, specializing in transforming sheet metal into high-performance parts with intricate shapes and superior durability. With over 26 years of experience, we ensure high precision, consistent quality, and efficient production for every project.

What Is Deep Drawing?

Deep drawing is a specialized metal fabrication process used to create three-dimensional components from flat sheet metal. Through controlled stretching and forming, the metal is shaped into the desired form within a die, offering numerous benefits for producing high-strength, precise components in various industries.

Unlike other metal forming methods, deep drawing allows for complex shapes with uniform thickness and high precision, which are critical for applications that demand strength and durability. This process is particularly useful when designing parts with intricate geometries, such as automotive components, enclosures, and containers.

Our Deep Drawing Process

Understanding the steps involved in deep drawing helps you appreciate how this process leads to high-quality, precision-engineered parts.

Design Review and Optimization

Every project begins with a comprehensive design review. Our experts evaluate the geometry, material properties, and dimensions to optimize the design for deep drawing, ensuring minimal material waste and maximum efficiency.Material Selection

After confirming the design, we carefully select the most appropriate material for the job. We consider the formability, strength, and durability needed to ensure that the material performs well throughout the deep drawing process and in the final product.Precision Forming

Using our advanced deep drawing presses, we transform the metal into the required shape with precision. Throughout the forming process, we maintain strict control to ensure each part meets the highest standards of quality.Thorough Quality Control

Following production, each component undergoes detailed quality checks. We inspect dimensions, surface quality, and consistency, using advanced measuring tools to ensure that every part complies with your specifications.

Key Advantages of Our Deep Drawing Services

Exceptional Precision and Consistency

With advanced equipment and skilled technicians, our deep drawing metal fabrication service ensures each part is formed to exact specifications. The process delivers uniform wall thickness, tight tolerances, and smooth surface finishes, ensuring the finished parts meet your exacting requirements.

Wide Material Compatibility

We offer deep drawing services for a variety of materials such as stainless steel, aluminum, copper, and more. Our deep understanding of material properties allows us to select the best material for your parts, optimizing performance, durability, and cost-effectiveness.

State-of-the-Art Equipment for Reliable Results

Our deep drawing presses and machinery are equipped with the latest technology, providing the necessary precision and efficiency for complex metal forming. This investment in cutting-edge equipment allows us to maintain consistent quality across all production volumes.

Flexible Production Capabilities

Whether you require low-volume prototypes or high-volume production runs, we can scale our deep drawing process to meet your needs. Our efficient approach ensures that quality is maintained across any production scale, ensuring timely delivery without compromise.

Comprehensive Service from Start to Finish

We provide end-to-end service, collaborating with you from the initial design stage through material selection, production, and final inspection. Our team ensures that each part is optimized for the deep drawing process, delivering the best possible outcome at every step.

Common Issues in Deep Drawing and How to Address Them

While deep drawing is an effective process, certain challenges can arise. Here’s a look at some of the most common issues, along with strategies to mitigate them:

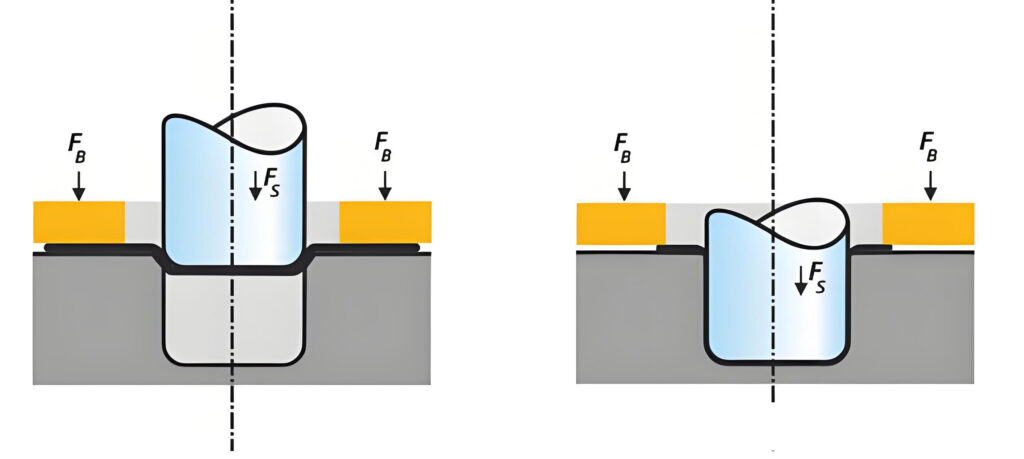

Wrinkling

Wrinkling occurs when the metal doesn’t flow smoothly into the die. This can be caused by insufficient blank holder pressure or poor die design. To prevent this, YISHANG uses optimized die designs and pressure controls to ensure smooth metal flow and minimal wrinkling.

Thinning and Tearing

Thinning or tearing happens when the material is stretched beyond its limits. This issue can be avoided by selecting the right material and adjusting the forming parameters, such as punch speed and depth, to ensure that the material is not overstrained.

Earing

Earing is a defect where the edges of the formed part become uneven. This can be caused by material inconsistencies or poor die alignment. At YISHANG, we use advanced techniques in die design and material selection to minimize the risk of earing, ensuring that every part meets the highest quality standards.

Deep Drawing vs. Other Metal Forming Techniques

While deep drawing offers many advantages, it’s not always the best option for every part. Other forming methods such as stamping and extrusion may be more suitable in certain cases.

Deep Drawing vs. Stamping

Stamping is typically used for simpler parts, but deep drawing is necessary for creating deeper and more complex shapes. If the part requires a high degree of complexity, deep drawing is the better choice, as it can produce parts with intricate details and deeper sections.

Deep Drawing vs. Extrusion

Extrusion is another method used to shape metal, but it works better for continuous shapes, such as tubes or bars. Deep drawing is more versatile for creating specific, enclosed, and three-dimensional parts.

Conclusion

Our deep drawing metal fabrication services offer a versatile, precise, and cost-effective solution for producing high-strength, complex components across various industries. At YISHANG, we specialize in providing tailored solutions that meet the unique needs of each client, from prototypes to large-scale production.

With YISHANG‘s deep drawing services, you get reliable, durable parts that perform under pressure and deliver value for your business. If you’re looking for high-quality components made with precision, we are here to help.