Why Assembly Is a Strategic Procurement Factor

In sheet metal manufacturing, assembly isn’t just about structural integrity—it directly influences usability and long-term functionality.

For procurement managers, the real cost goes beyond just the unit price; it lies in how well parts integrate downstream. Issues like misaligned welds, distorted tabs, or inconsistent fasteners can cause delays and installation difficulties.

Even minor defects can disrupt large-scale production. OEMs prioritize assembly precision as much as material specifications, especially in industries like telecommunications, energy storage, and EV charging stations, where durability and speed are critical.

Form vs Function: What Assembly Means for Procurement Decisions

When making procurement decisions, teams focus on more than just unit price. Assembly methods impact usability, packaging, shipping, and even future maintenance.

For modular electrical cabinets, welding ensures rigidity but complicates post-coating processes. Mechanical fastening, however, allows for precision and ease of maintenance, making it the ideal choice for flat-pack delivery. This method is favored in industries such as telecom and smart grid infrastructure.

Key procurement priorities include:

Consistency across batches

Assembly speed on-site

Ease of future maintenance

For example, telecom enclosures favor threaded inserts and self-clinching fasteners, while EV charging infrastructure may require hybrid approaches that combine spot welding and mechanical fasteners.

Choosing the Right Assembly Method: A Logic-Based Framework

Using the wrong joining method can lead to scrap, rework, and delays. Instead, adopting a logic-driven framework simplifies decision-making.

Key questions to ask:

Is disassembly required later?

Will the joint be subject to movement, weight, or vibration?

Is surface finish or conductivity a factor?

Matching the need to the method:

Permanent joints: MIG/TIG/laser welding, adhesive bonding

Semi-permanent joints: Bolts, rivets, captive screws

Hybrid joints: Snap-fit tabs + adhesives, rivets + assembly threads

This framework is especially useful for complex assemblies like electric assembly units or painted components where heat application is constrained.

Thermal Joining: Strength and Speed

MIG, TIG, and Spot Welding

MIG welding is preferred for structural frames, offering high deposition rates, commonly used for equipment racks, vending machines, and heavy-duty displays.

TIG welding produces clean seams, ideal for stainless steel, aluminum, or visible cabinetry where aesthetics are essential.

Spot welding is favored for overlapping parts, delivering high-strength bonds ideal for battery modules, power supply enclosures, and kiosk frames.

However, welding can cause heat distortion, necessitating post-weld adjustments for painted or coated components.

Soldering & Brazing

Soldering is ideal for light-load electrical assemblies, such as electric panels or enclosure terminals.

Brazing bonds metals without excessive heat, making it suitable for dissimilar materials.

Laser Welding

Laser welding provides precise seams with minimal warpage, making it ideal for high-end electronics and medical enclosures that demand both thermal control and aesthetic finishes.

Mechanical Fastening: Precision, Serviceability, and Scalability

Mechanical fastening provides repeatable and reversible joints, crucial for modular and export-ready systems.

Screws, Bolts, and Inserts

These provide torque control and field maintenance capabilities. Proper alignment supports telecom racks, display housings, and precision enclosures.

Riveting

Blind rivets provide a secure fastening solution with one-side access, ideal for server cabinets, HVAC housings, and control box enclosures.

Self-Clinching Fasteners

These eliminate thread cutting, saving time in high-speed batch production, particularly in electronics frames and sheet metal electrical assemblies.

Hinges and Captive Elements

Hinges, captive screws, and toggle latches provide reusable access in kiosks, panels, and distribution boxes, reducing tool dependency during installation.

Adhesive and Cold Joining: Clean, Non-Thermal Integration

Structural Adhesives

Acrylics, epoxies, and urethanes are used for high-performance assemblies in energy storage enclosures, telecom shells, or signage structures.

These adhesives reduce stress points and prevent part deformation, especially in thin aluminum or mixed-metal assemblies.

Combined with mechanical features like alignment tabs or clinched seams, adhesives create durable joints.

Clinching

Clinching is used to join coated or aluminum panels without heat, ideal for air ducts, control boxes, or electro-mechanical casings.

Hemming

Hemming adds rigidity and reduces sharp edges, ideal for cabinets, signage, or transportable displays.

Snap Fits & Tabs

Snap fits and slot tabs simplify rapid assembly, reducing tool usage and enabling scalable production for machined parts, signage displays, and modular fixtures.

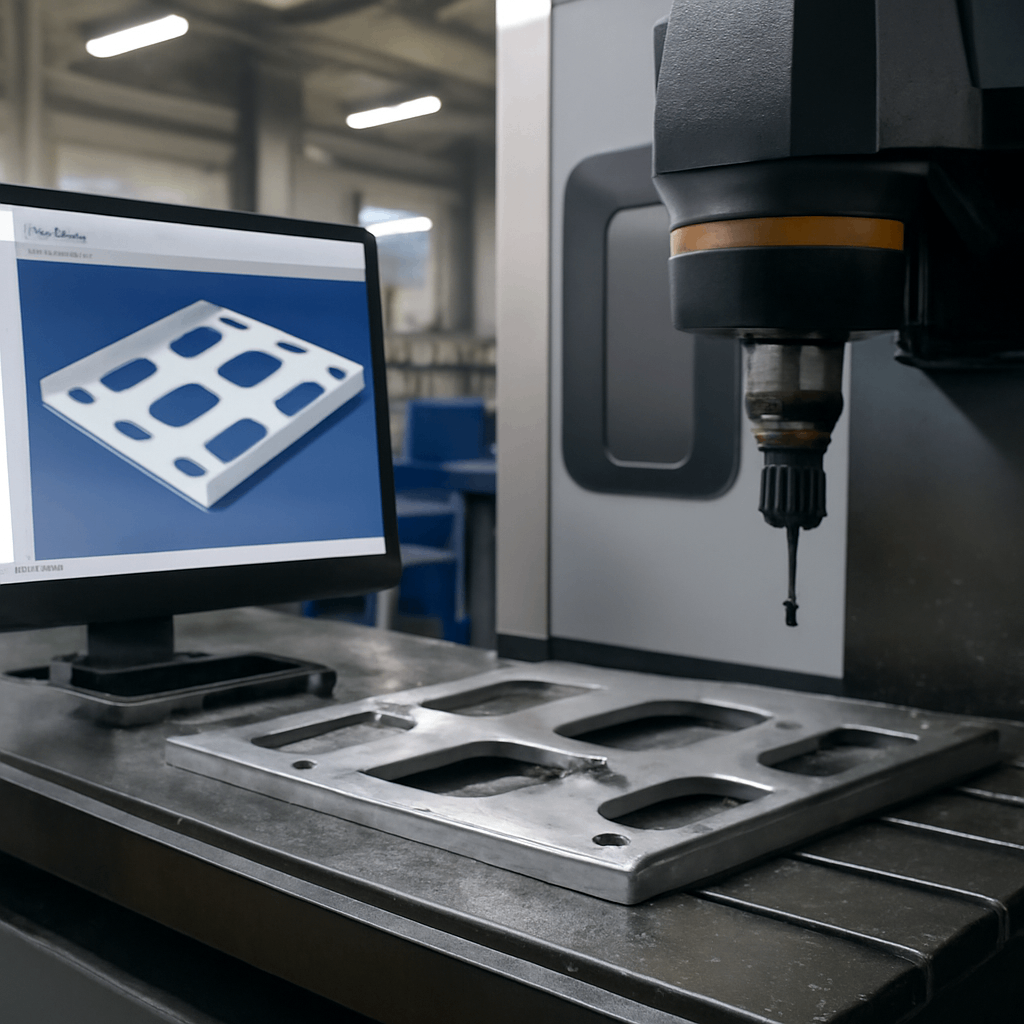

From CAD to Production: Assembly-Aware Design

At YISHANG, we work closely with buyers from the design phase to ensure seamless assembly:

Fastener placement and clearance for automated installation

Pre-validated assembly threads for consistent torque

Tolerance stack-up simulations to ensure compatibility across production runs

Incorporating these strategies at the CAD stage reduces scrap and ensures electromechanical assemblies arrive ready to use.

Use Cases: Matching Assembly to Application

| ApplicationAssembly MethodsWhy It Works | ||

|---|---|---|

| Modular Fixtures | Snap Tabs + Adhesive + Rivets | Flat-pack ready, deployment-ready |

| Charging Stations | MIG + Clinch + Bolts | Durable, vibration-safe |

| Server Enclosures | Self-Clinch + Threaded Inserts | Clean access, wiring clearance |

| Battery Housings | Adhesive + Hemming | Lightweight, sealed, scalable |

These use case scenarios help procurement managers match performance to cost expectations.

Future-Proofing Assembly: What B2B Buyers Should Track

All assemblies are ISO 9001 and RoHS-compliant for international markets.

Smart Fastening

Smart fastening technologies such as sensors and torque monitoring are essential for industries like EV infrastructure and medical devices.

Modular, Reusable Joints

Clients prioritize modular designs for easy disassembly, particularly in OEM cabinet fabrication, reducing lifecycle costs.

Compliance-Centered Assembly

As regulatory standards tighten, we use RoHS-compliant adhesives, recyclable materials, and VOC-free adhesives to meet international compliance. For outdoor enclosures, cold-joining or sealed fabrication methods are ideal.

Conclusion: Streamlined Assembly, Stronger Results

Efficient sheet metal assembly reduces costs, speeds up installation, and improves product reliability. YISHANG partners with global OEMs to deliver scalable, production-ready sheet metal assemblies.

Ready to optimize your next build? Contact YISHANG for expert assembly solutions tailored to your needs.