Introduction: Why Fabricated Sheet Metal Boxes Matter for Global Procurement

In international wholesale sourcing, metal box fabrication plays a critical role in delivering enclosure solutions for electronic, industrial, and energy systems. These aren’t just containers — they protect components, support efficient assembly, and help products meet global compliance standards.

This article gives sourcing professionals and purchasing managers a practical perspective on choosing the right sheet metal fabrication company. It covers how YISHANG, a precision sheet metal fabricator with 26+ years of experience, helps you go from CAD to scalable delivery — all while ensuring competitive cost, technical support, and compliance for overseas procurement.

What is Metal Box Fabrication? A Procurement-Critical Process

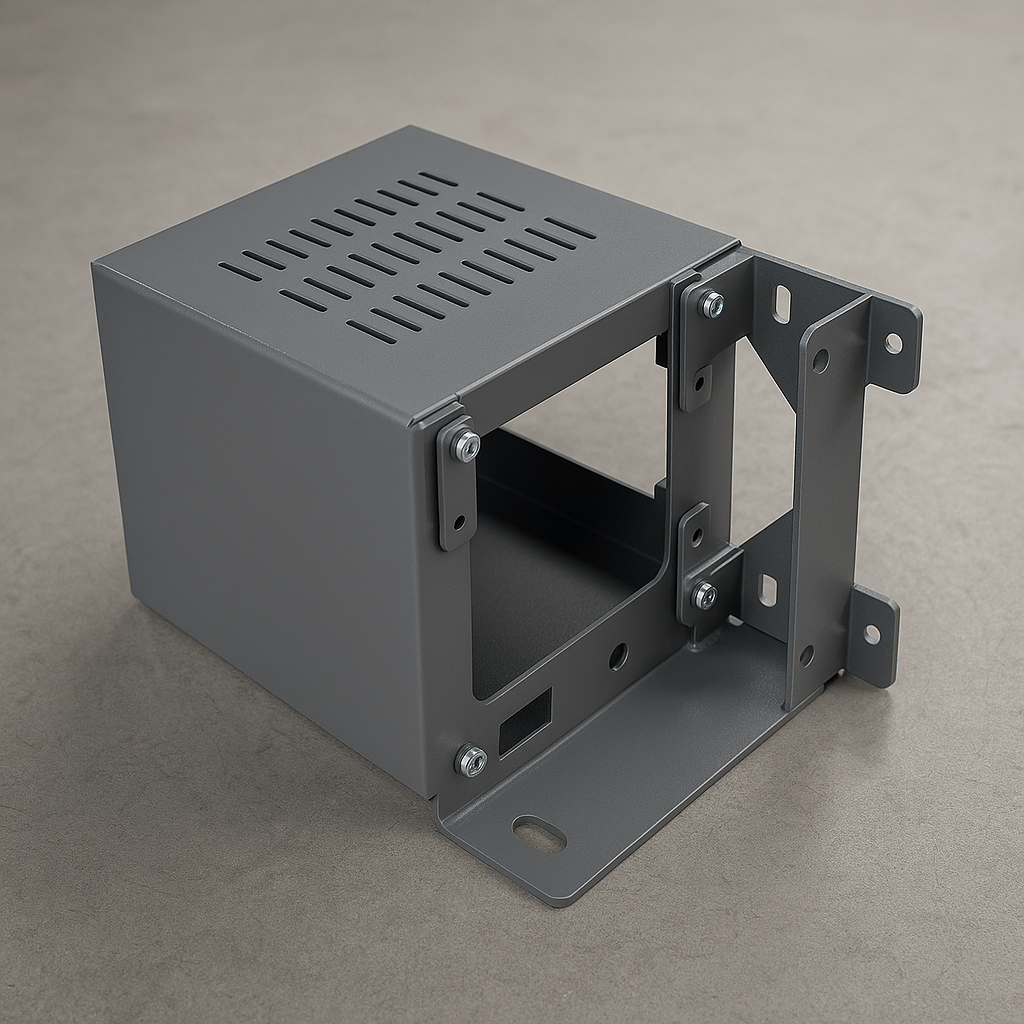

Metal box fabrication refers to the process of designing and manufacturing protective enclosures, housings, and control boxes using sheet metal materials like stainless steel, aluminum, or galvanized steel. These fabricated metal boxes are essential across sectors such as electronics, industrial automation, power systems, and medical equipment.

The fabrication process typically involves precision cutting, bending, joining (such as TIG/MIG welding or clinching), and surface finishing. Metal box fabrication ensures durability, corrosion resistance, and compatibility with installation systems. Well-fabricated boxes support safe component housing, efficient assembly, and long-term performance in both indoor and outdoor environments.

For global wholesale buyers, choosing the right metal box fabrication partner reduces lead times, lowers field failure risks, and ensures compliance with international standards like RoHS, IP ratings, and ISO certifications.

From Design to Deployment — Metal Box Fabrication Built for Procurement

Fabricated metal boxes made from steel and aluminum do more than enclose—they represent reliability, integration readiness, and shipment quality.Poor enclosures can delay assembly, cause field failures, or breach local standards.

That’s why custom metal box fabrication is more than a technical job — it’s a procurement-critical decision. At YISHANG, we work with contract buyers to develop precision sheet metal products optimized for their applications and distribution models.

We align box functionality with shipping, batch scalability, and warehouse handling. Engineers simulate fit, access, and assembly ease. By building fast-attach features (like hinges, slots, and tool-less access) into the design, we eliminate many problems that arise downstream.

From inquiry to prototype shipment typically takes 7–12 days based on complexity. For most of our clients, quick sampling and responsive DFM feedback are what make YISHANG more than just a vendor — we become part of your sourcing process.

Our RFQ response time is typically within 24 hours with a detailed breakdown, allowing you to make timely and confident purchasing decisions.

Our material recommendations also reflect use conditions — not just availability. For example, aluminum for weight-sensitive boxes, or 316 stainless steel for marine use. Here’s a functional breakdown:

| Material Type | Properties & Value Add | Industry Fit |

|---|---|---|

| SS 304 | Strong, food-grade, common export | Kitchen appliances, healthcare |

| SS 316 | High corrosion resistance | Marine, chemical, medical |

| Galvanized Steel | Cost-efficient, corrosion resistant | basic metal box fabrication |

| Aluminum | Lightweight, conductive, rust-resistant | EVs, aerospace, outdoor use |

We accommodate custom sheet metal parts and work with sheet gauges suited for different structural needs, including alum sheet metal gauges used in electronics.

A client in Germany reduced 35% freight costs with our flat-packed kiosk enclosures — by combining modular designs with optimized carton sizes and ISPM-15 certified wooden crating.

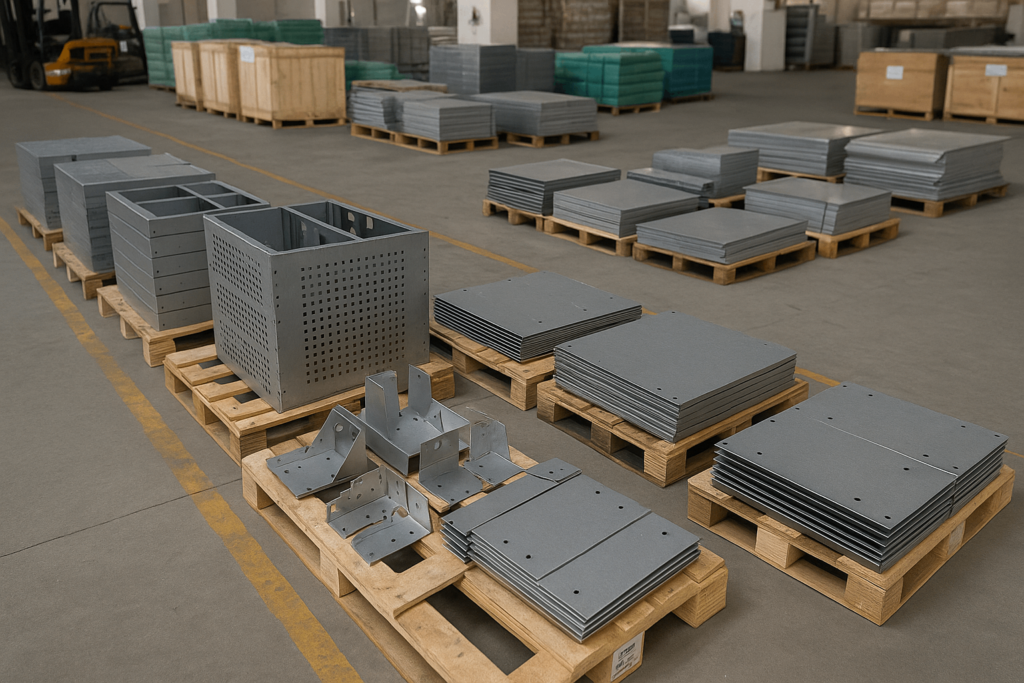

Fabrication Workflow: Built for Predictability & Scale

At YISHANG, our fabrication process supports high consistency from prototype to mass production. This matters to procurement teams managing batch timelines and cost control.

Precision Cutting, Forming & Tooling

We use CNC punching, laser cutting, and precision sheet metal forming to maintain ±0.2mm tolerances. Our processes suit scale production with repeatable accuracy. Tooling is optimized for volume — we use modular dies to shorten setup for repeat orders. Reduce cost per unit by consolidating designs into multi-use tooling — a strategy we regularly suggest to high-volume customers.

Joining, Finishing & Flat-Packing

Welding (MIG, TIG, spot) is backed by internal fixturing and QC. When applicable, clinching and PEM inserts are used to reduce distortion and allow disassembly. Boxes can be flat-packed to reduce container volume, cutting export freight costs.

Surface finishes meet ASTM B117/D3359 corrosion tests. We also offer powder coating, anodizing, and brushed finishes. For every order, we provide export-grade packaging: ISPM 15 wooden crates, reinforced cartons, and labeled pallets.

If your project requires color-matching or multi-language labeling, we support that as part of our export services.

Designed for Industries That Demand Consistency

We support sectors where enclosures are compliance-critical:

Automotive sheet metal parts: EV battery housings, control panel boxes

Medical devices: Sterilizable casings with non-porous surfaces

Smart devices: Thermal-vented, shielded boxes with cutouts

Retail/industrial: Kiosk enclosures, branded POS structures, custom metal box fabrication

We supply sheet metal contract manufacturer documentation like batch test reports, RoHS material declarations, and assembly manuals — saving time for your compliance teams.

Need to update drawings during pre-production? No problem — we accept mid-stream revisions and provide updated samples for confirmation before bulk fabrication begins.

Why Procurement Managers Choose YISHANG

We’re not a generic sheet metal factory — we’re a contract-ready partner. Procurement teams worldwide trust YISHANG because we offer:

Low MOQ starting at 100 pcs

Fast sampling in 5–7 business days

File compatibility: STEP, DWG, PDF

Packaging tailored to LCL/FCL shipments

Clear labeling and export documentation

Over 80% of our overseas clients are repeat purchasers, many for over 5 years — a testament to consistent service, transparent communication, and responsive problem-solving.

We align with your logistics model and schedule. Our team supports English communication and offers fast updates, ensuring your project stays on track from inquiry to final container.

Conclusion: Get More Than Just Boxes — Get Supply Confidence

A precision box isn’t just a technical detail — it affects your lead times, customer satisfaction, and cost performance. At YISHANG, we build scalable, compliant, procurement-friendly enclosures that help global buyers move faster.

Our experience spans 50+ countries and thousands of custom sheet metal fabrications. Let’s make your next procurement project smoother.

Tell us what you need — we’ll handle the drawings, samples, packaging, and delivery.

Frequently Asked Questions (FAQ)

Q1: What is your minimum order quantity (MOQ)?

Our MOQ is typically 100 pieces per item, but we support smaller trial orders depending on complexity.

Q2: Can I request a sample before mass production?

Yes. We offer samples within 5–7 working days. Samples help validate form, fit, finish, and function before volume commitment.

Q3: What’s your average lead time for production?

For most orders, our lead time ranges from 15–25 days after sample approval and deposit confirmation, depending on order size and complexity.

Q4: Do you provide export documentation and support international shipping?

Absolutely. We provide full export documentation, support LCL/FCL shipments, and offer ISPM-15 certified wooden packaging when needed.

Q5: What industries commonly use metal box fabrication?

Metal box fabrication is widely used in electronics, medical devices, automation systems, telecommunications, and retail infrastructure. It provides reliable protection for components while supporting safe installation, grounding, and regulatory compliance.