I. The Buyer’s Nightmare: When “Impossible” Derails Your Supply Chain

Every innovative product begins with a design. For an engineer, it’s a breakthrough. For a procurement manager, it’s a critical component that must be sourced reliably and cost-effectively.

The nightmare starts when that design is rejected by suppliers as “unmanufacturable” or “too complex.” This is more than a technical problem; it’s a direct threat to your project’s timeline, budget, and go-to-market strategy. These fabrication challenges quickly become business-critical risks, forcing costly redesigns that compromise performance and delay launch.

But what if “impossible” is simply a limitation of your supplier’s process maturity? At YISHANG, we believe a manufacturing miracle is not a stroke of luck. It is the structured, predictable, and scalable conversion of a challenging concept into a compliant, production-ready sheet metal product—meeting every specification from the first prototype to the ten-thousandth unit.

In this article, we’ll unpack how strategic fabrication partners turn complex sheet metal design problems into a competitive edge for wholesale buyers and industrial procurement teams.

II. The Blueprint for Scalability and Cost Control: A DFM Guide for Strategic Sourcing

The greatest impact on a product’s cost structure and manufacturability happens before any metal is cut. This is where Design for Manufacturability (DFM) proves its value—not just as a design concept, but as a cost and risk control mechanism.

While many vendors treat DFM as a passive checklist, a qualified partner like YISHANG uses it as an early-stage diagnostic tool to identify preventable risks and unlock scalable value. For strategic sourcing professionals, this transforms DFM from a design consideration into a business-critical process.

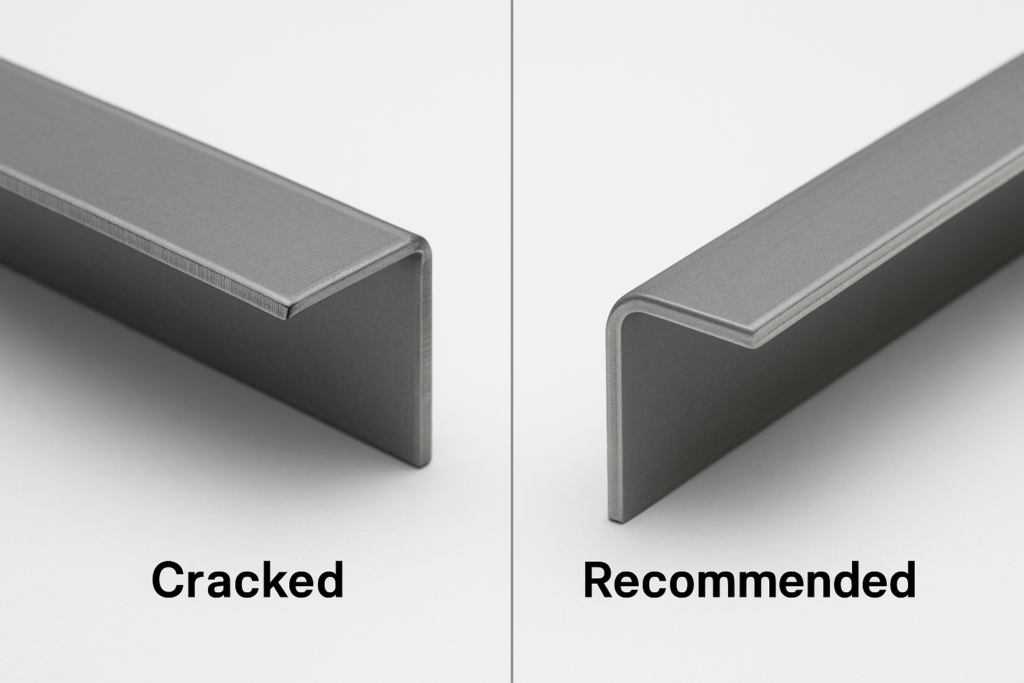

Problem 1: The Cracking Corner – A Threat to Long-Term Durability

One of the most common defects in sheet metal is cracking along a bend. This typically results from a bend radius that’s too tight for the material grade or thickness. While often overlooked, this flaw introduces latent failure risks in the field.

Preventing it involves evaluating material specs during the quoting phase and advising on the correct minimum bend radius. A supplier who flags this early demonstrates not just manufacturing knowledge but investment in your product’s long-term performance.

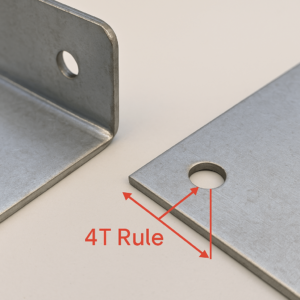

Problem 2: The Warped Hole – The Enemy of Efficient Assembly

A precise bend but a deformed mounting hole? It’s a recipe for chaos on the assembly line. Elongation or distortion of holes near bends leads to misaligned installs and manual rework.

Applying the “4T Rule”—placing any feature at least four times the material thickness away from the bend—prevents these issues. A supplier versed in such practices helps ensure every unit fits seamlessly into downstream processes.

Problem 3: The Post-Heat-Treat Warped Panel – A Hidden Cost Driver

Selecting a low-cost carbon steel may seem economical—until the part warps during heat treatment. Yield loss, rework, and dimensional instability become hidden cost drivers that sabotage TCO.

A seasoned partner might recommend alternatives like 410 Stainless Steel for better thermal stability. This small material change reduces distortion and increases process reliability, benefiting procurement KPIs like yield, throughput, and defect rate.

Problem 4: The Assembly Line “Tolerance Trap” – A Recipe for Failure at Scale

Individually perfect parts that don’t fit together often fall victim to tolerance stack-up. This occurs when acceptable variations in each part combine to exceed system tolerances.

Collaborative design reviews help define critical vs. non-critical dimensions. This not only reduces cost by relaxing unnecessary tolerances but ensures reliable assembly performance—especially critical in B2B scaling scenarios.

III. The Right Tool for Predictable Outcomes at Scale: A Process Selection Matrix

DFM gives you the design insights. But achieving consistency at scale requires the right fabrication technologies. For procurement teams, process capability equals risk control.

At YISHANG, we’ve built a hybrid manufacturing environment—combining CNC turret punching, fiber laser cutting, MIG/TIG welding, and robotic automation. This enables us to match each job with the most efficient workflow.

| If Your Sourcing Challenge Is… | The Optimal Process & Why It Matters | The Risk of a Less Capable Supplier |

|---|---|---|

| High-volume with both simple and complex features | Hybrid Manufacturing: CNC Turret Punch + Fiber Laser. Reduces handling and secondary ops, improving cost and lead time. | Single-method shops either struggle with detail or require costly extra steps. |

| Welds that must be flawless | Manual TIG Welding: Precision and aesthetics combined. Ensures cosmetic and functional success. | Using MIG instead risks weak welds and poor finish, harming product reliability. |

| Large runs of structural frames | Robotic MIG Welding: Speed and consistency. Ensures repeatability and cost control. | Manual welding at volume introduces inconsistency and QC risk. |

IV. From the Trenches: Real-World Proof of Risk Mitigation and Performance

Procurement doesn’t operate on promises—it operates on proof. These recent project snapshots demonstrate our ability to deliver precision sheet metal components under demanding regulatory, environmental, and functional constraints.

For wholesale buyers and OEM procurement teams, these stories reveal how the right partner mitigates risk across the lifecycle—from design sign-off to scaled delivery.

The Sterile Challenge: Engineering a Microbe-Resistant Medical Enclosure

A global medical equipment supplier needed a blood analysis machine enclosure. Requirements included seamless TIG welds, no crevices, and a surface Ra finish under 0.8µm to meet hygienic standards.

We selected certified 316L stainless steel and deployed fiber laser cutting and expert TIG welding. Robotic polishing delivered the required finish. The enclosure passed validation on first inspection—accelerating the client’s FDA submission timeline.

The Fortress: Building a BESS Enclosure to Defend Against Thermal Runaway

A U.S.-based renewable energy integrator needed an IP66-rated BESS enclosure compliant with NFPA 855. Challenges included venting for thermal events, weatherproof sealing, and high corrosion resistance.

We engineered in NFPA 68-compliant blowout panels, performed HMA simulations, and applied marine-grade powder coating. The result was a field-proven enclosure that protects both battery integrity and end-user safety.

Taming the Untamable: Machining and Welding an Inconel 718 Aerospace Component

An aerospace tier supplier needed a turbine nozzle in Inconel 718—an extremely hard-to-machine nickel alloy. Requirements included tight tolerances, dimensional stability post-welding, and CMM-verified precision.

Using slow-feed end mills, heat-sink fixturing, and post-weld heat treatment (PWHT), we delivered full-batch parts that passed ultrasonic testing and were accepted without rework.

V. Your Supplier Vetting Blueprint: 5 Questions to Ask Any Fabrication Partner

In the RFQ stage, asking the right questions reveals whether a supplier can support your growth—not just fill a PO.

- “How do you handle DFM collaboration before quoting?”

Early input equals fewer surprises. A mature supplier invests time before numbers are on the table. - “Can you share similar projects by industry and spec?”

Experience in related applications gives you confidence in execution. - “What dimensional control methods do you use?”

Look for documented inspection plans, CMM data, and gauge traceability. - “Can your shop integrate multiple fabrication processes?”

Shops with hybrid capacity reduce risk, lead time, and cost. - “What’s your repeatability process for large-scale runs?”

Consistency demands automation, ISO 9001 discipline, and lot traceability.

VI. Beyond the Part: Building a Resilient Supply Chain with YISHANG

When a drawing is marked “too complex” by other suppliers, that’s when our real work begins.

At YISHANG, we don’t just fabricate parts—we eliminate bottlenecks, prevent defects, and engineer out risk. From custom sheet metal enclosures to precision components, we’ve helped global OEMs move from uncertainty to supply chain confidence.

If you’re facing a tough sourcing challenge—or want to prevent the next one—partner with a fabrication team that thrives on complexity.

Let’s turn your impossible into a scalable, manufacturable success.