The First Decision, Not the Last Step: Why Surface Finish Defines Product Success

For procurement professionals managing global supply chains, the choice of a surface finish is far more than an aesthetic detail; it is a critical decision that directly impacts product reliability, lifecycle costs, and brand reputation.

Viewing the finish as a functional component—not merely a cosmetic addition—mitigates long-term risk. A poorly matched finish can introduce failure points that escalate into costly warranty claims and unplanned field replacements.

Conversely, a well-specified finish is an investment in quality assurance. It protects the part in its environment, ensures regulatory compliance, and sustains long-term performance. This guide outlines practical parameters for finish selection, grounded in real-world tolerancing and testing challenges.

The Finisher’s Arsenal: A Visual Glossary of Core Processes

To make informed procurement decisions, a clear understanding of metal surface treatment options is essential. This comparison table introduces the major finishing processes, their core principles, and associated limitations for quick reference.

| Finish Family | Specific Process | How it Works (The 10-Second Science) | Best For… (Primary Mission) | Watch Out For… (Known Limitations) | Relative Cost |

|---|---|---|---|---|---|

| Organic Coatings | Powder Coating | Electrostatically charged polymer powder is sprayed onto a grounded part and cured with heat, forming a hard, plastic skin. | Extreme durability, excellent corrosion resistance, and a wide variety of colors and textures for aesthetic parts. | May produce uneven thickness in recesses; unsuitable for heat-sensitive substrates; prone to Faraday cage effect in internal corners. | $$ |

| Organic Coatings | E-Coating (Electrophoretic) | Part is immersed in a water-based paint solution; electric current deposits paint particles uniformly over the entire surface, including internal cavities. | Reliable corrosion protection and consistent coverage on complex geometries; commonly used as an automotive primer. | Requires topcoat for UV protection; fewer aesthetic options than powder coating. | $ |

| Plating | Zinc Plating (Electroplating) | A thin layer of zinc is deposited on steel using electric current in an electrolyte bath. | Budget-friendly sacrificial corrosion protection for steel fasteners and automotive components. | Uneven distribution on complex geometries; low abrasion resistance compared to advanced coatings. | $ |

| Plating | Electroless Nickel Plating | A nickel-phosphorus alloy is chemically deposited (autocatalysis) without electric current, achieving a uniform layer. | Exceptional uniformity on intricate parts; enhanced corrosion and wear resistance; suitable for non-conductive materials. | Slow application and high chemical cost; bath stability demands strict monitoring. | $$$ |

| Anodizing | Type II & Type III Anodize | An electrochemical process that thickens the natural oxide layer on aluminum, increasing hardness and corrosion resistance. | Type II: Decorative corrosion resistance. Type III: Superior durability and hardness for demanding applications. | Only for non-ferrous metals; can crack on flexible parts; Type III can slightly alter dimensions. | $-$$$ |

| Conversion Coatings | Passivation | Stainless steel is treated (citric or nitric acid) to remove free iron, enhancing its natural corrosion resistance. | Optimizing corrosion resistance for stainless steel, especially in medical and food-grade environments. | Does not alter surface appearance or add mechanical strength; requires thorough pre-cleaning. | $ |

| Conversion Coatings | Chromate / TCP Coating | A chemical layer is formed on aluminum or zinc, improving corrosion resistance and paint adhesion. | Protects while maintaining electrical conductivity; ideal for coating prep on aluminum. | Hexavalent versions face environmental restrictions; limited wear resistance. | $ |

The Decision Framework: 4 Critical Questions Before Specifying Any Finish

Choosing the right finish requires technical and commercial clarity. These four key questions streamline the decision-making process and improve cross-functional communication.

1. What is the Battlefield? (Analyzing the End-Use Environment)

The intended environment determines the finish performance. A mismatch here can reduce product life and create downstream risks.

In marine or coastal applications, use a multi-layer finish: zinc primer, epoxy barrier coat, and UV-stable polyurethane topcoat. For validation, seek salt spray test results per ASTM B117—ideally 1,000+ hours.

For chemical or industrial environments, finishes must resist specific agents. In medical and food-grade applications, surface hygiene matters. Finishes like electropolishing or passivation—meeting 3-A Standards and achieving <0.8µm Ra—are essential.

2. What is the Mission? (Defining Key Functional Requirements)

Some finishes serve a function beyond appearance or corrosion resistance.

For conductive needs, choose finishes like chromate conversion coatings. In contrast, powder coatings and anodizing are electrical insulators.

In high-friction components, wear resistance is vital. Choose Type III anodizing or hard chrome plating to extend component life and reduce maintenance.

When used as a paint base, conversion coatings create ideal adhesion surfaces. A poorly prepped part may suffer coating failure—leading to costly returns.

3. What are the Design’s Hidden Traps? (Mastering Design for Finishing – DFF)

YISHANG’s experience reveals many finishing challenges stem from upstream design. Small changes can avoid major production issues.

- Faraday cage effect affects coating uniformity. Design with radii and avoid deep recesses to ensure consistent coverage.

- Sharp edges inhibit adhesion. Adding chamfers allows coatings to anchor securely.

- Coating buildup affects assembly. Powder coatings can add up to 0.254mm (0.010″), so tolerances must be adjusted accordingly.

4. What is the True Cost? (A Beyond-the-Quote Analysis)

Unit price is only part of the picture. Evaluate the total cost of ownership (TCO) by factoring in lifecycle durability, failure rates, and reputational risks.

An upgraded finish may increase part cost, but if it drastically reduces failures, the ROI is often significant. This is strategic sourcing in practice.

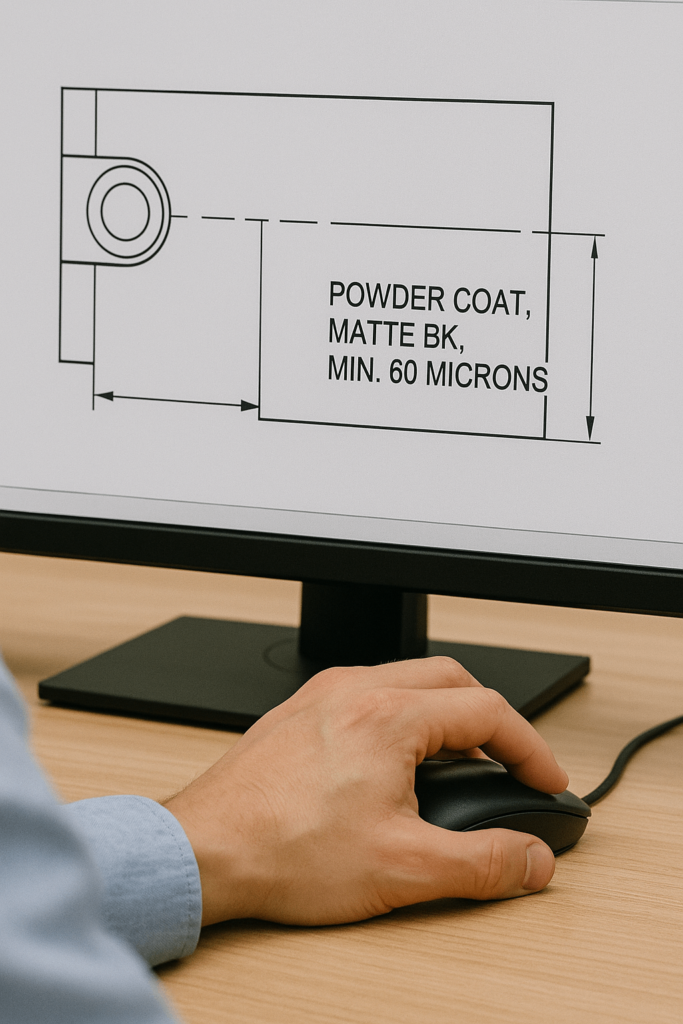

From CAD to Reality: How to Specify Finishes on a Technical Drawing

Precise drawings avoid miscommunication. Always reference full standards—for instance, “Anodize per MIL-A-8625, Type II, Class 1, Black” instead of “Anodize.”

Mark uncoated areas clearly for masking—especially for grounding or assembly. This detail is essential for production consistency.

YISHANG frequently supports OEM clients with finish selection and drawing annotations, especially when designs involve multiple coating systems or pre-treatment masking.

The Horizon: Where Surface Technology is Headed

The future of finishing lies in compliance and intelligence.

RoHS and REACH regulations push the industry toward safer options like Trivalent Chromium Pretreatments (TCP).

Smart coatings now offer functions like self-healing, antimicrobial protection, and hydrophobicity. The market is expected to grow from USD 4.7B in 2025 to over USD 18.1B by 2035.

These emerging technologies have potential implications for sectors like medical device manufacturing, EV battery enclosures, and outdoor kiosk fabrication—several of which YISHANG currently serves.

The Engineer’s Quick-Reference Matrix

| If Your Primary Goal Is… | Your Top Finish Candidates Are… | Key Design Consideration | Relevant Standard to Cite |

|---|---|---|---|

| Maximum Corrosion Resistance in a Marine Environment | Hot-Dip Galvanizing (Steel), E-Coat + Powder/Polyurethane Coat System | Ensure drainage holes for dipping processes; design to avoid Faraday cage effects for spray systems. | ASTM A123 (Galvanizing), ASTM B117 (Salt Spray Test) |

| Extreme Wear & Abrasion Resistance | Type III Hardcoat Anodize (Aluminum), Hard Chrome Plating (Steel), Electroless Nickel (High Phosphorus) | Account for significant thickness buildup in tolerances; radius sharp external corners to prevent chipping. | MIL-A-8625, Type III (Hardcoat), AMS 2469 (Hardcoat) |

| Maintaining Electrical Conductivity | Chromate Conversion Coating (or Trivalent TCP), Gold/Silver Plating | Ensure the finish is not insulative; clearly mask off areas if only partial conductivity is needed. | MIL-DTL-5541 (Chem Film), MIL-G-45204C (Gold Plating) |

| Achieving a Food-Grade or Medical-Grade Surface | Passivation (Stainless Steel), Electropolishing (Stainless Steel) | The surface must be smooth and crevice-free; aim for a surface roughness (Ra) of < 0.8µm. | ASTM A967 (Passivation), 3-A Sanitary Standards |

| A Durable, Aesthetic Finish with a Wide Color Choice | Powder Coating | Design with generous internal radii to avoid the Faraday cage effect; account for 0.004″-0.010″ thickness buildup. | N/A (Specify RAL color code and gloss level) |

| Cost-Effective, General-Purpose Corrosion Protection | Zinc Plating (Steel), Type II Anodizing (Aluminum) | Zinc plating offers poor abrasion resistance; Type II anodizing is an electrical insulator. | ASTM B633 (Zinc Plating), MIL-A-8625, Type II (Anodizing) |

Navigating the complexities of sheet metal finishing requires a partner who understands both the technical details and your business objectives. Looking to integrate performance-oriented finishes into your OEM production line? Let YISHANG’s engineers support your DFM and surface strategy.