In high-volume manufacturing, a single number on a technical drawing can define a component’s profitability. This isn’t a theoretical exercise—it directly impacts your supply chain and bottom line. Consider a real-world case: an audio equipment faceplate where a blanket tolerance of ±0.01mm was specified for a “premium feel.” The initial quote was $220 per unit.

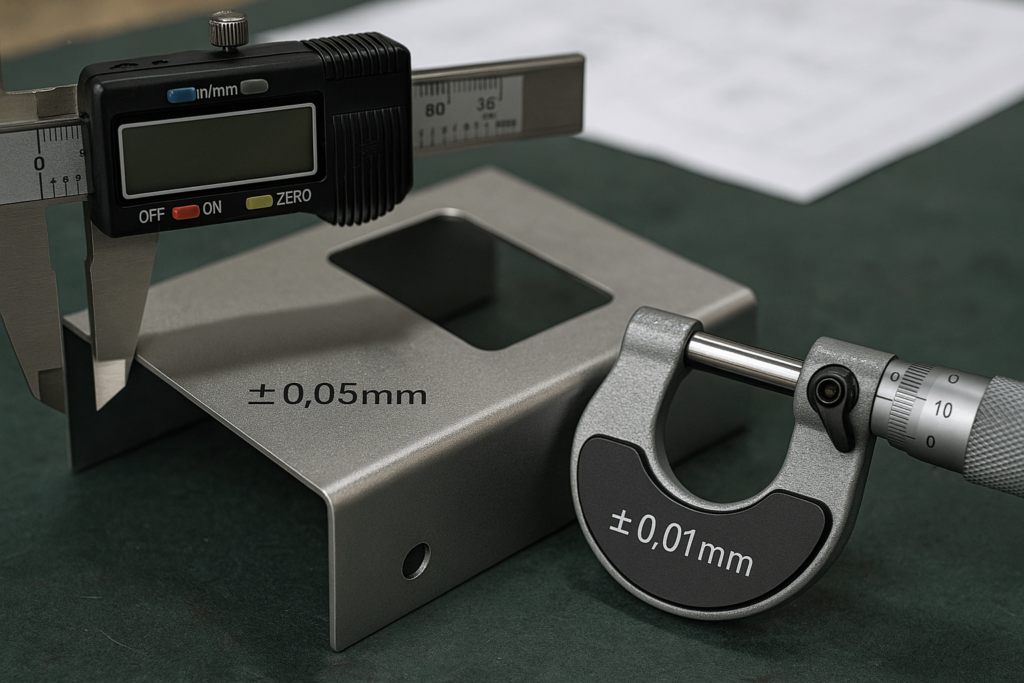

After a targeted design review, only two alignment holes retained this precision. Other dimensions were revised to a standard ±0.05mm. The result? A fully functional part at just $95—a 57% cost reduction. Multiply that across thousands of units, and the savings become transformative.

This case highlights a key principle for procurement professionals: sheet metal tolerancing is not about maximum precision, but functional precision. Every tolerance affects unit cost, lead time, and supplier capability. This guide equips B2B buyers and engineers with a strategic playbook for navigating tolerances, avoiding budget pitfalls, and optimizing manufacturability at scale.

Revealing the “Cost Cliff”: Why Your Design is Secretly Burning Money

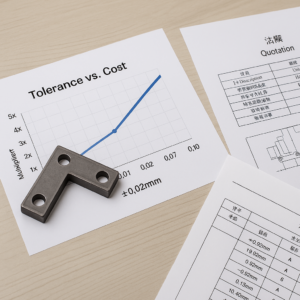

Tolerance and cost are not linearly related—they follow a steep curve. For global sourcing managers, understanding this cost curve is essential to achieving reliable pricing across high-volume orders.

Over-tolerancing—specifying unnecessary tight tolerances—is a silent budget killer. It leads to inflated quotes, specialized tooling, and high scrap rates, all triggered by one overly ambitious number on a drawing.

The ±0.02mm Cost Cliff Explained

Analysis of thousands of real-world fabrication quotes reveals a consistent tipping point: the ±0.02mm Cost Cliff. Tolerances below this shift production from standard processes to specialized, cost-intensive methods.

Above ±0.02mm, parts are made efficiently using standard tools and QC protocols. Below this threshold, machine feed rates slow, setups become complex, and 100% CMM inspection replaces sampling. This increases cost and delays.

Data-Driven Cost Multipliers

Here’s how unit cost responds to changes in tolerance range, with tangible impact across your sourcing and logistics chain:

| Tolerance Change | Impact on Unit Cost | Key Drivers Affecting Your Supply Chain |

|---|---|---|

| Loosening: ±0.05mm to ±0.1mm | 20–30% Savings | Standard tooling, faster cycle times, reduced inspection overhead. |

| Tightening: ±0.05mm to ±0.02mm | 50–80% Cost Increase | Slower machine speeds, more complex setups, increased quality checks. |

| Crossing the Cliff: < ±0.02mm | 200–400% Cost Increase | Specialized tooling, full CMM inspection, higher scrap rates, longer lead times. |

The “Budget Killers”: High-Cost Features to Watch Out For

Some features create massive cost spikes when over-toleranced:

- Deep Holes: Depths >5x diameter. ±0.01mm can increase cost 3.5x due to special tooling and breakage risk.

- Thin Walls: <2mm in aluminum, <3mm in stainless. Tight tolerances here require custom fixturing.

- Large Flatness Zones: Flatness <0.05mm across large surfaces may require secondary grinding, inflating cost 2.5x.

Specifying tolerances is ultimately an act of risk management. The question isn’t “Can this be made at ±0.01mm?” but rather “Does the benefit justify the cost, complexity, and potential delay?”

Mastering the 4 “Invisible Forces” That Limit Your Tolerances

Understanding manufacturing physics helps procurement teams predict risk. These invisible forces are where precision gains or losses begin.

Force 1: The Material’s “Personality” (Inherent Variation)

Sheet metal starts with variation—especially thickness. A 3.0mm sheet may vary ±0.25mm per standard tolerances. This affects all downstream processes.

Different metals react differently: stainless is stable, while soft aluminum alloys may deform easily. Grain direction from rolling also influences bend behavior.

Force 2: Forming’s “Memory” (Springback & K-Factor)

Bent metal “remembers” its original flat state. This springback must be anticipated using K-factor calculations. Mastering bend allowance enables accurate, repeatable forms.

Force 3: The Process’s “Fingerprint” (Manufacturing Limits & HAZ)

All processes leave a precision fingerprint. Laser cutting offers ±0.13mm, but introduces a Heat Affected Zone (HAZ). Forming widens tolerance, especially on hole-to-bend distances.

Force 4: Welding’s “Ripple Effect” (Assembly Distortion)

Thermal distortion from welding causes shrinkage and warping. Mitigation requires skilled sequencing, balanced welds, and heat management to retain dimensional integrity.

The Engineer’s Action Handbook: 3 Strategies for a Cost-Function Win-Win

Understanding cost drivers is only step one. The next is applying that insight through engineering discipline and supplier collaboration.

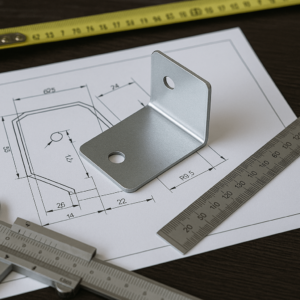

Strategy 1: Defensive Design (Proactive DFM)

Designing out problems is the cheapest solution. Apply Design for Manufacturability (DFM) rules to avoid tolerance-driven cost spikes:

- Respect Bend Radii: Inner radius ≥ 1T to prevent cracking.

- Avoid Holes Near Bends: Keep clear at least 2.5T + 1 radius.

- Apply ISO 2768 Where Applicable: Use default tolerances for non-critical dimensions to reduce drawing complexity.

ISO 2768-1 (Medium Class) – General Linear Tolerances

| Dimension Range (mm) | Permissible Deviation (mm) |

|---|---|

| 3 – 6 | ±0.1 |

| 6 – 30 | ±0.2 |

| 30 – 120 | ±0.3 |

| 120 – 400 | ±0.5 |

Strategy 2: Functional Language (Strategic GD&T)

GD&T communicates more than size—it communicates function. Tools like Profile of a Surface control multiple aspects of a feature at once, ideal for complex assemblies.

Strategy 3: Global Vision (Mastering Tolerance Stack-Up)

In large assemblies, individual part tolerances stack. Use RSS (Root Sum Square) methods to manage accumulated variance and ensure total functional fit.

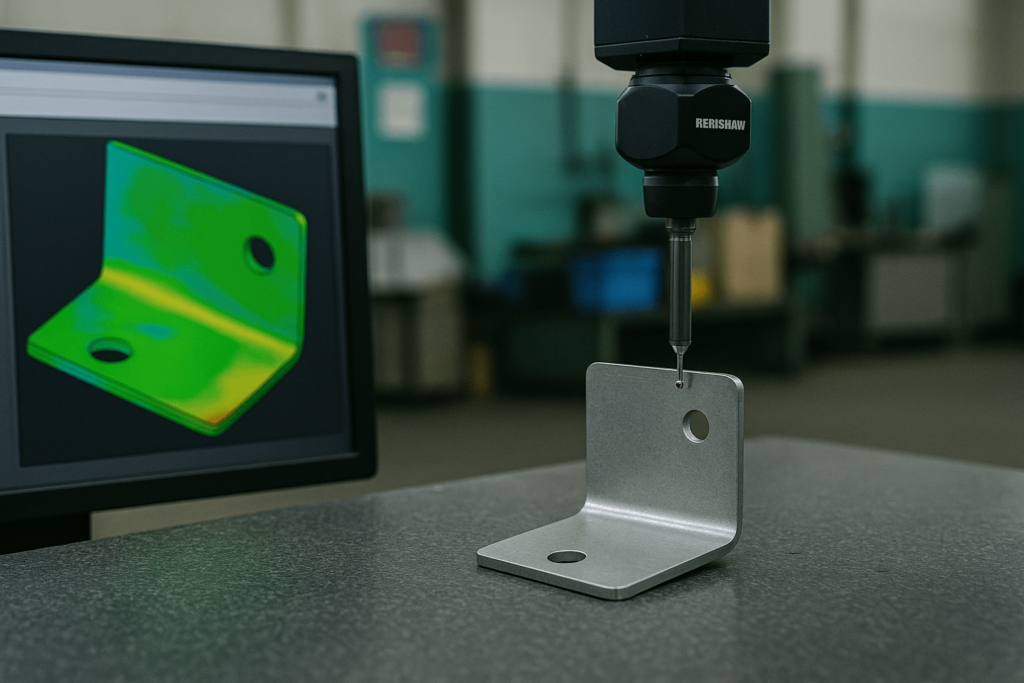

From Blueprint to Reality: How to Verify “Precision” at Scale

Precision only matters if you can measure it effectively—especially at production volumes.

“Point vs. Picture”: CMM vs. 3D Laser Scanning

- CMM (Coordinate Measuring Machine): Best for single-point, high-accuracy checks.

- 3D Scanning: Captures full surface maps, ideal for analyzing complex parts or comparing batches.

“Reactive vs. Proactive”: The Power of SPC for High-Volume Production

Statistical Process Control (SPC) empowers predictive quality. Tracking trends reveals drift early, minimizing rework and maintaining throughput.

Conclusion: Becoming a Tolerancing Master Starts with an Expert Partner

Precision is not about tighter numbers—it’s about making every tolerance serve a purpose. That means balancing engineering intent with cost and manufacturability.

With 26+ years of experience and ISO 9001 certification, YISHANG is a precision sheet metal supplier serving 50+ global markets. We specialize in high-volume custom parts and proactive tolerance optimization.

Ready to reduce cost and improve yield on your next project? [Request a Free Tolerance Review with YISHANG].