Introduction: Beyond Decoration — The Real Value of Screen Printing on Metal

Silkscreen on metal is more than just a finishing step—it’s a critical part of durable industrial and OEM labeling. In industrial and commercial product design, it plays a functional role in durability, compliance, and customer perception. Whether it’s a warning label on a control cabinet or a clean, brand-consistent nameplate on a printed metal enclosure, the value lies in performance and reliability.

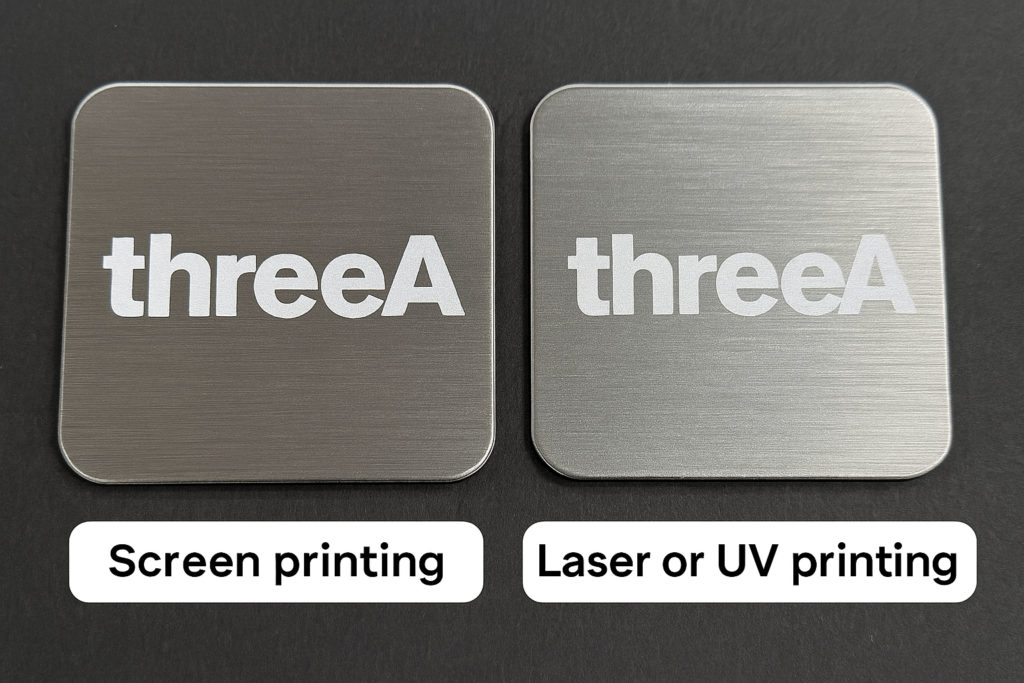

Compared to UV or laser techniques, silkscreen on metal offers superior durability and ink thickness—making it the preferred method for lasting, high-contrast graphics.For OEM procurement, especially in high-volume or custom RFQs, it’s not about choosing a trend — it’s about reducing lead time risk and ensuring consistency.

At YISHANG, we understand global buyer priorities: consistency, cost-efficiency, sample-to-production continuity, and clear documentation. With 26+ years of export experience and a track record across 50+ countries, we deliver screen printed solutions that support industrial, automotive, and electronics production lines.

What Is “Silkscreen on Metal”? Understanding the Basics

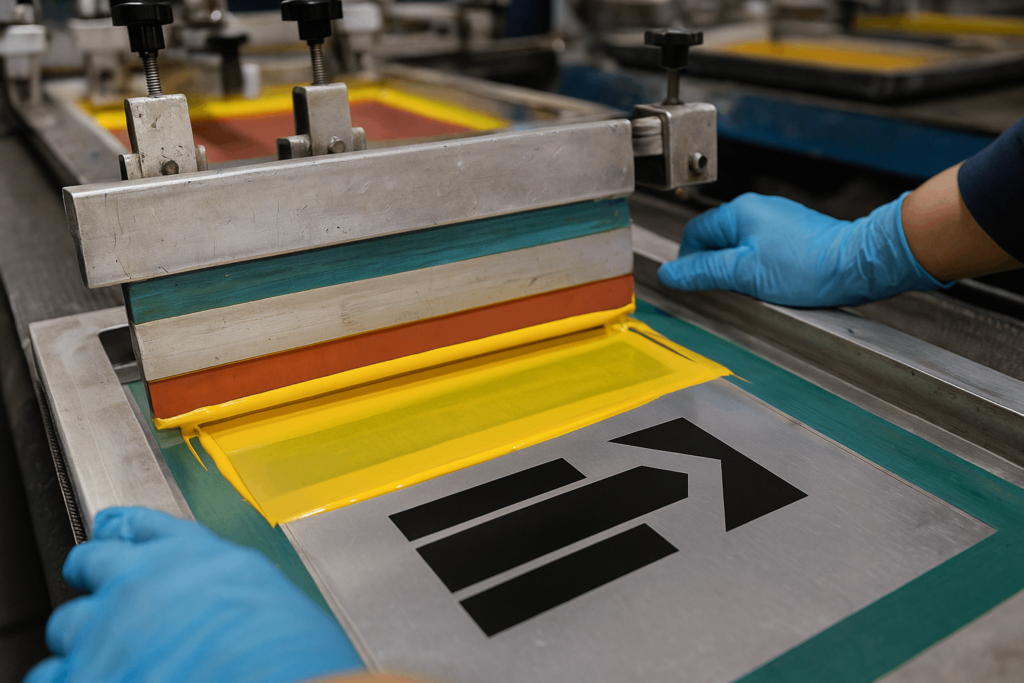

“Silkscreen on metal” refers to the process of applying durable inks through a mesh stencil onto metal surfaces—such as aluminum, stainless steel, or galvanized steel. This method is widely used to create long-lasting graphics, labels, and functional markings on equipment or components.

Compared to UV printing or laser engraving, silkscreen on metal stands out for its:

Thicker ink deposits for improved visibility and wear resistance

Stronger adhesion, especially when paired with epoxy or UV-cured inks

Cost-efficiency in medium to high production runs

Silkscreen on metal is ideal for:

Nameplates and product tags

Industrial signage

Control panel graphics

OEM labels requiring high contrast and longevity

At YISHANG, our silkscreen processes are optimized for both technical performance and bulk order repeatability.

Why Screen Printing on Metal Remains a Reliable Procurement Choice

For volume buyers, durability isn’t optional—it’s expected. Industrial screen printing delivers stronger ink bonding, color integrity, and substrate adaptability. Unlike UV inkjet, which risks lifting on uncoated surfaces, or laser marking, which lacks visual contrast, screen printing ensures legibility under real-world stress.

Procurement managers in B2B environments prioritize performance over process. Our printed metal tags and graphic overlays endure:

UV exposure on outdoor units

24/7 cleanroom wipe downs

High-vibration zones in engine bays

Epoxy and UV-curable inks used at YISHANG adhere deeply to metals like stainless steel and anodized aluminum. The result: fewer reprints, fewer field failures.

This means your parts arrive ready for compliance inspections, not correction notices.

Choosing the Right Metal: Where Engineering Meets Procurement

Buyers managing RFQs for industrial or regulated markets understand this well: ink is only as good as the surface it touches.

304/316 Stainless Steel is ideal for medical, marine, or hygiene applications. It requires roughening or plasma activation to ensure adhesion.

Anodized Aluminum is a buyer favorite for weight-to-cost and long-term clarity. Its micro-porous layer locks in the ink layer and minimizes ghosting.

Galvanized Steel serves well for cost-sensitive OEM signage and labels but needs primer pretreatment.

Copper & Brass look excellent but oxidize quickly. They’re common in low-quantity premium designs or decorative faceplates.

Every quote from YISHANG includes coating compatibility review and surface energy data. This keeps you from learning costly lessons post-delivery.

Inks & Coatings: The Real Barrier Between You and Batch Failure

Poor adhesion or faded graphics result in rejections. That’s why we match every ink system to substrate + usage profile.

Epoxy Ink: 2-part, ideal for oil-exposed environments and metal tags on equipment.

UV Ink: Fast-cure, VOC-free, designed for coated metals and high-run control panel labels.

Solvent Ink: Used on embossed or flexible substrates where shaping follows printing.

We test adhesion and resistance through:

ASTM D3359: Adhesion grading

ISO 2409: Cross-cut performance

ASTM B117: Salt fog simulation for outdoor labels

Whether you’re delivering into energy, med-tech, or telecom, this testing protects your batch from costly rework.

Mesh & Ink Selection: Engineering the Perfect Print

To ensure batch-to-batch consistency, both mesh count and ink formulation must be tailored to your graphic and substrate:

Mesh Count:

100–120 T for bold logos and thick prints (e.g., outdoor signage)

200–300 T for fine detail on aluminum or stainless steel

Mesh Material:

Polyester for general use

Stainless steel mesh for high-temperature or solvent-heavy applications

Ink-Substrate Match:

Epoxy for stainless steel

UV-curable for anodized aluminum

Solvent-based for shaped/embossed panels

Our in-house database matches mesh + ink to more than 100+ material/usage combinations to reduce guesswork in procurement.

End-to-End Workflow Built for Global Supply Chains

Once the print material and ink chemistry are matched, execution quality determines outcome.

Design & File Prep: RFQ response includes artwork review, film proofing, and mesh resolution suggestions.

Screen Engineering: We track mesh count, emulsion curve, and tension settings per lot. Screen IDs can be recalled for reorder.

Ink Mixing & Print Pass: Inks are weighed and logged. Custom control panel labels or aluminum tags are printed with calibrated squeegee angle and pass count.

Curing & Inspection: Thermal curing at 150–180°C or UV polymerization ensures permanence. QA reports include pass/fail data.

Labeling & Packing: We bundle QA docs and batch IDs with every crate. For large orders, we add serial coding and carton identifiers.

Buyers receive a solution—not just a shipment.

Use Cases That Influenced Our Clients’ Decisions

Electronics & Instrument Panels

A European automation integrator reduced label failure by 62% after adopting our anodized aluminum overlays with UV ink. Our parts passed 5,000 alcohol wipe cycles and survived climate chambers up to 85°C.

Automotive Subsystems

One tier-1 supplier in EV cooling systems saw batch rejection drop by 45% across six months. Our printed metal tags maintained readability after 1,200 hours of heat and humidity cycling.

Medical Instruments

A diagnostic OEM needed screen printed stainless steel plates for autoclave exposure. Our epoxy ink passed FDA compatibility checks and ISO 13485 visual requirements without additional coating steps.

Renewables & Outdoor Equipment

For inverters and solar units, fade-free labels matter. A Southeast Asia client saw 30% better readability in the field after upgrading to YISHANG’s salt-spray-tested nameplate systems.

These aren’t case studies—they’re buyer outcomes.

Failure Prevention: Procurement Risk Is a Process Problem

Reorders that don’t match samples. Labels that peel during final inspection. Missed lead times due to curing inconsistencies. Sound familiar?

Our prevention methods reduce batch rejection cost:

Plasma-treated metals eliminate flaking

Ink viscosity logged for every run

Jig-based alignment prevents drift

Curing logs linked to each serial number

YISHANG’s rework rate on global orders? Under 2% for the last 18 months.

For buyers, this means one less variable to chase.

Why Screen Printing Outperforms Laser & Digital for Industrial Labels

Compared to laser etching or digital UV methods, silk screen offers:

| Feature | Screen Printing | Laser Marking | Digital Printing |

|---|---|---|---|

| Outdoor Durability | ★★★★★ | ★★★☆☆ | ★★☆☆☆ |

| Color Opacity on Metal | ★★★★★ | ★☆☆☆☆ | ★★★☆☆ |

| Ink Thickness | Up to 50 μm | N/A | <10 μm |

| Surface Adhesion | ★★★★☆ | N/A | ★★☆☆☆ |

| Cost Efficiency (Bulk) | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

In regulated industries, bold visibility and permanence often outweigh aesthetic subtleties. Screen printing delivers function over flash.

Conclusion: A Better Print Process Built Around What Buyers Care About

Silk screen printing isn’t just a production method—it’s your assurance of clarity, consistency, and compliance. When it supports medical tools, energy systems, or your client’s brand, quality control is non-negotiable.

YISHANG provides OEM-ready metal label solutions, tested and verified for global buyers. Our service includes rapid prototyping, lead time transparency, and full traceability.

FAQ

Q: How do you ensure repeatability across large batches?

A: We log screen tension, mesh type, ink batch, and curing parameters. Each production run is tagged with a unique ID linked to your RFQ. This ensures your 1st order and 50th reorder remain identical.

Q: Can you print conductive or functional inks?

A: Yes. We support carbon, silver, and dielectric inks used for sensor arrays, membrane switches, and EMI shielding. These are screen printed with cleanroom SOPs in place.