Introduction: The Supply Chain Risk of a “Good Enough” Bend

For a wholesale buyer, even a minor deviation in part geometry can lead to serious supply chain disruptions. Picture this: a shipment of 5,000 custom components arrives, and by the time you reach the thousandth piece, a small angular error has emerged.

Suddenly, your automated assembly line halts. Weld jigs fail to align. What seemed like an insignificant flaw escalates into a production bottleneck—costing thousands in lost hours and delaying entire projects. This is the hidden danger of a “good enough” bend, a risk savvy procurement professionals can’t ignore.

While high-end press brake machines are often the focus of evaluation, they are only part of the equation. The real safeguard against cumulative errors and dimensional drift is the skilled press brake operator—the human factor that ensures consistency, accuracy, and production integrity. This is the foundation of precision metal forming in high-mix manufacturing. This article sheds light on why operator expertise matters just as much—if not more—than machine capability.

Inside Skilled Press Brake Forming—Deconstructing the Operator’s Mind

The distinction between a novice and an expert operator is not merely about years of service—it’s about their ability to interpret material behavior, anticipate failure points, and make adaptive decisions during forming. Their value lies in blending theoretical understanding with hands-on experience to achieve batch-level consistency.

From Blueprint to Reality: The First Line of Defense in Quality Control

A seasoned operator doesn’t just follow the blueprint—they analyze it. They visualize the complete bend sequence before touching the machine, mentally unfolding flat patterns into finished geometry. This ability helps prevent tooling collisions and ensures formability across the entire workpiece.

This analysis relies heavily on their fluency with Geometric Dimensioning and Tolerancing (GD&T) and real-world production considerations, such as allowable deviation zones and fixture interaction. By validating the drawing’s feasibility at the pre-production stage, they reduce wasted material, rework, and downstream errors. Learn more about GD&T standards.

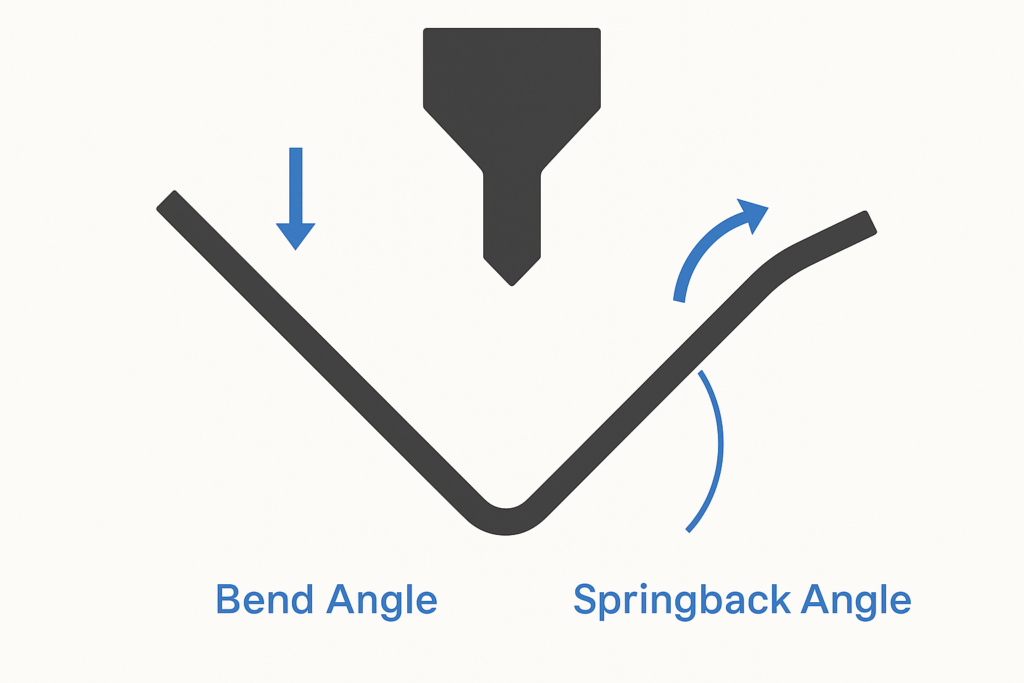

The Physics Whisperer: Taming Springback and K-Factor for Batch Consistency

Precision bending is rooted in physics. Operators must understand how materials respond to stress, particularly how they “spring back” after release. These variations depend on thickness, tensile strength, and temper—and must be compensated for in every batch.

Rather than relying on theoretical defaults, a skilled operator tests, observes, and calibrates. They adjust for K-factor discrepancies, which impact bend allowance and ultimately the unfolded flat pattern dimensions. By capturing and applying these empirical adjustments, they ensure dimensional stability over thousands of parts.

The Master Diagnostician: Solving Bending Headaches to Prevent Delays

Skilled operators don’t just prevent problems—they solve them in real time. Three common forming issues demonstrate how practical expertise impacts production:

- Inconsistent Angles (“Canoeing”): Typically caused by uneven die pressure or worn tooling. Expert operators apply crowning adjustments to restore even distribution.

- Cracking on the Bend Line: Often the result of bending against the grain or using too tight a punch radius. Operators respond by selecting appropriate tools or altering orientation.

- Surface Marks and Scratches: Linked to dirty or damaged tooling. A skilled operator identifies and resolves this proactively before cosmetic issues affect quality.

Why Automation Alone Can’t Guarantee Quality—The Human Judgment Advantage

Modern CNC press brakes offer speed and repeatability—but they are not autonomous quality control systems. Material variability, tool wear, and shop-floor realities constantly introduce variables that no software algorithm can completely anticipate.

When Sensors Miss What Operators See

Sensors detect measurements; humans interpret behavior. When a digital gauge flags an angle deviation, only a trained eye can determine whether it’s due to inconsistent stock, tool fatigue, or process instability.

Operators observe how the sheet reacts to bending, listening to the press, watching deformation, and even sensing vibration changes. These real-time feedback mechanisms are irreplaceable in preventing runaway defects.

Adaptive Thinking in an Unpredictable Production Environment

Not every variable is programmable. Sheet flatness, burr accumulation, or residual stress from upstream processes (like laser cutting) may affect bend results. When patterns emerge, it takes human pattern recognition to trace anomalies back to root causes.

Rather than correcting individual parts, skilled operators correct the process—modifying sequence, adjusting clamping, or compensating fixture setups—to safeguard the integrity of the entire batch.

Beyond Programming: Nuance, Not Just Numbers

Machines execute instructions. Operators execute intent. Tolerance conformance on paper does not always translate to functional fit. A ±0.5° error may technically pass, but if it misaligns with downstream parts, it’s still a defect.

The operator bridges this gap—choosing, for example, to shift bend order or slightly offset tooling to ensure assembly compatibility. These intuitive adjustments, invisible to software, have visible impacts on product performance.

The Financial and Operational ROI of Skilled Press Brake Talent

Procurement professionals are tasked with balancing cost and consistency. Skilled operators reduce both hidden and visible costs—not through discounts, but through process stability and minimized rework.

Labor is a Line Item. Scrap and Downtime Are Not.

Lower labor costs mean little when they produce higher scrap rates. Consider this comparison:

- Supplier A: Low labor rate, but 6% scrap rate and 45-minute changeovers.

- Supplier B: Higher operator skill, 1% scrap rate, and 20-minute setups.

Over a 10,000-piece job with frequent tool changes, Supplier B yields lower total cost—even if their per-part price is higher. Skilled labor minimizes waste, compresses cycle time, and ensures smoother flow through production.

Skilled Operators Improve OEE (Overall Equipment Effectiveness)

Operators directly influence OEE’s three components:

- Availability: Fewer setup errors = more uptime

- Performance: Optimal parameters = faster cycles

- Quality: Correct first parts = fewer reworks

Low OEE often signals high variability. Skilled operators drive OEE upward through consistency, repeatability, and preventive attention to detail.

Why Skilled Labor is an Asset, Not a Premium

Rather than viewing labor as a cost center, skilled press brake operators should be seen as value multipliers. They are embedded quality assurance—detecting potential issues before they become delivery failures.

For buyers, evaluating the operator’s knowledge and judgment is just as vital as reviewing the equipment list. It’s the human decision-making at the press brake that turns digital design into dimensional reality.

How to Evaluate a Supplier’s Press Brake Capabilities—What to Ask Before You Buy

To separate high-performance partners from the rest, ask questions that uncover who’s actually running the machines and how quality is enforced.

Who Programs and Sets Up the Press Brake?

Request clarity on the programming process. Is it engineer-driven, or reviewed by operators with hands-on tooling knowledge? Is the same person performing setup also checking part outputs?

At YISHANG, operator-programmers collaborate with engineering to fine-tune parameters—bridging digital intent with on-site experience.

What Metrics Do You Use to Validate Forming Accuracy?

Look for suppliers that implement:

- First-article inspection with documented results

- Laser angle sensors and real-time deviation logging

- Material-specific springback adjustment protocols

YISHANG’s system includes test-run validation, bend allowance calibration, and documented traceability for all batches.

How Are Operators Trained and Assessed?

Beyond basic safety, are operators trained in material science, GD&T interpretation, and problem-solving? At YISHANG, our team members undergo continuous training and are assessed on both accuracy and efficiency.

A mature training program signals that the factory doesn’t rely on individuals, but invests in scalable talent infrastructure.

Can You Show Me a Time-Sensitive Forming Job You’ve Delivered?

Ask for real examples. A supplier able to discuss setup challenges, defect troubleshooting, and adaptive solutions during a tight timeline demonstrates operational maturity.

Look for decision-making moments, not just finished parts. These stories reveal whether skilled thinking happens when it matters most.

Conclusion: Investing in Precision Is Investing in People

As automation increases, human expertise becomes even more important—not less. Skilled press brake operators are the final assurance of dimensional integrity, real-time responsiveness, and continuous process improvement.

You’re not just sourcing metal parts. You’re sourcing the consistency, quality, and reliability that only well-trained professionals can guarantee.

At YISHANG, our strategy blends high-precision press brakes with skilled operators trained in both theory and craft. All press brake calibration and batch verification procedures are conducted under ISO 9001-compliant protocols, and all supplied parts meet RoHS standards. We believe the best machines deserve the best people—and that your business deserves nothing less.

Because precision isn’t just a capability. It’s a commitment.

If you’re sourcing high-precision bent parts or evaluating long-term metal fabrication partners, we invite you to discuss your project with our team. Our skilled operators and engineering support staff are ready to help you ensure accuracy, efficiency, and reliability at scale.