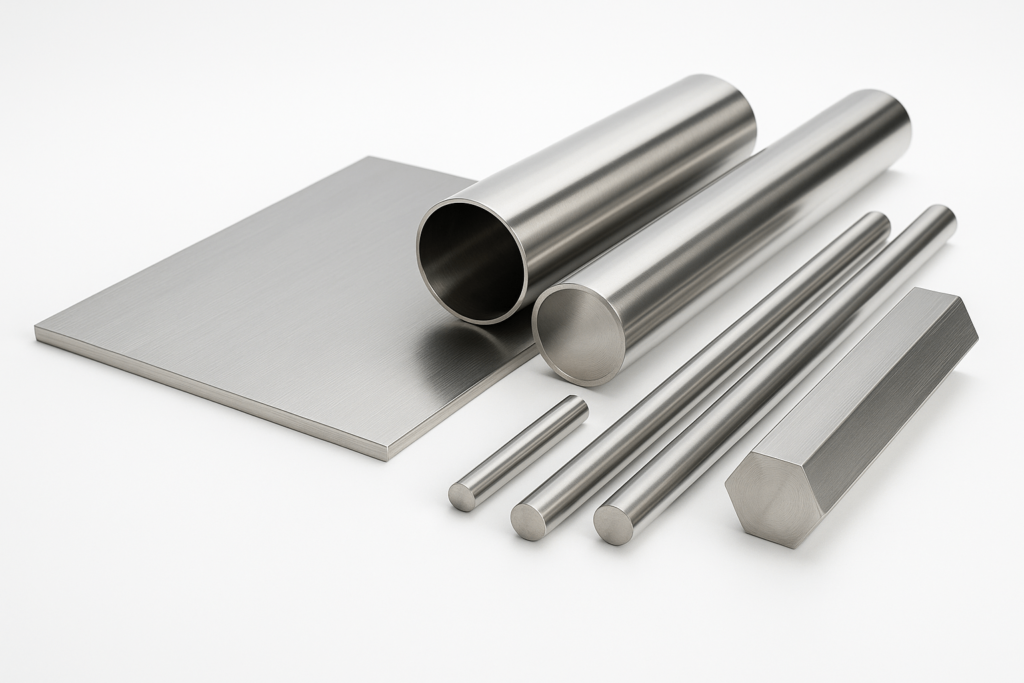

Introduction: Why Material Selection Is Critical for OEMs and Fabricators

For OEM buyers, industrial engineers, and wholesale procurement teams, selecting the right stainless steel is far more than a routine decision—it affects service life, corrosion resistance, and total cost of ownership.

From the widely used grade 304 stainless steel to specialized duplex and PH alloys, every grade has a unique chemical makeup that governs its behavior in fabrication, welding, and real-world applications. These are not just metallurgical facts—they are the foundation for smarter sourcing, manufacturing, and engineering outcomes.

This comprehensive guide breaks down stainless steel composition in practical terms. You’ll learn how alloying elements like chromium, molybdenum, and nitrogen impact corrosion resistance, machining properties, and application fit. Whether you’re sourcing custom stainless steel parts, overseeing CNC stainless steel machining, or evaluating suppliers, this guide helps align material performance with your production goals.

Part 1: What Makes Steel “Stainless”—The Passive Layer in Action

Understanding why stainless steel resists corrosion starts with surface chemistry. When chromium content reaches a critical threshold, it enables a self-forming, invisible barrier.

1.1 Chromium Content: Why 10.5% Is the Turning Point

Stainless steel contains at least 10.5% chromium, which reacts with oxygen to create a stable, inert chromium oxide (Cr₂O₃) film. This passive layer separates the steel from moisture and air, protecting it from rust—unlike plain carbon steel.

This layer regenerates on its own, making stainless steel inherently resistant to surface damage and oxidation. For OEM and B2B buyers, this means less maintenance and longer operational lifespans.

1.2 Self-Healing Properties: Surface Recovery in Real Time

If scratched, the passive film reforms automatically, provided oxygen is present. This prevents corrosion propagation—an advantage over painted or coated metals.

In industrial settings, where mechanical wear and chemical exposure are routine, this self-repairing ability provides long-term protection.

1.3 The Role of Chemical Passivation in Fabricated Parts

During fabrication—especially CNC machining or welding—particles of free iron may become embedded on the surface. This interferes with the passive film.

Post-processing chemical passivation (per ASTM A967) removes contamination, allowing the passive layer to regenerate properly. It’s a critical step for ensuring corrosion resistance in OEM stainless steel parts destined for demanding environments.

Part 2: Five Stainless Steel Families and Their Engineering Profiles

Stainless steel grades fall into five primary categories based on their internal crystal structure. These classifications help engineers and purchasers select the right alloy for mechanical performance, corrosion resistance, and cost.

2.1 Austenitic (304, 316): Most Common, Most Versatile

With a Face-Centered Cubic (FCC) structure, austenitic grades are known for excellent ductility and weldability. Nickel stabilizes the structure and enhances corrosion resistance.

304 stainless steel(18/8): High formability, used in food equipment, industrial piping, and architecture316 stainless steel: Includes molybdenum for better chloride resistance, ideal for marine, medical, and chemical processing use

Non-magnetic and tough at low temperatures, austenitic grades are widely used in industrial fabrication.

2.2 Ferritic (430): Lower Cost, Magnetic, and Functional

Ferritic steels have a Body-Centered Cubic (BCC) structure. They use less nickel, reducing material cost. While they are more brittle and less formable than austenitic types, ferritic steels resist stress corrosion cracking.

430 stainless steel is a common example used in appliance interiors and automotive trim, often compared to 304 in cost-sensitive applications.

2.3 Martensitic (420, 440C): Hardenable and Wear-Resistant

Martensitic grades can be hardened through heat treatment, making them suitable for high-stress applications like turbines, blades, and valves. They generally offer lower corrosion resistance.

440C: High hardness, used for bearings and cutting tools

2.4 Duplex (2205): Strength Meets Corrosion Performance

Duplex stainless steel combines FCC and BCC phases, balancing strength and corrosion resistance. 2205 duplex stainless delivers:

- Yield strength over 450 MPa

- Excellent chloride stress corrosion cracking resistance

Common in pressure vessels, offshore platforms, and structural components.

2.5 Precipitation-Hardening (17-4 PH): High Precision, High Strength

PH stainless steels use heat treatment and elements like niobium to achieve high mechanical strength without compromising corrosion resistance.

17-4 PH: Machinable before aging, ideal for aerospace, defense, and energy applications

2.6 Stainless Steel Grade Comparison Table

[Table retained here for direct comparison of grades.]

Part 3: Key Alloying Elements in Stainless Steel and What They Do

Each alloying element in stainless steel serves a function. Together, they allow engineers to fine-tune materials for strength, corrosion resistance, and workability.

- Nickel (Ni): Stabilizes austenite, improves toughness and weldability

- Molybdenum (Mo): Increases resistance to pitting and crevice corrosion

- Nitrogen (N): Strengthens austenitic grades without sacrificing ductility

- Carbon (C): Essential for hardness in martensitic grades

- Manganese, Copper, Silicon: Improve formability, oxidation resistance, and lower alloy cost

This is critical for applications involving CNC stainless steel machining, deep drawing, or forming operations—processes that demand predictable material behavior.

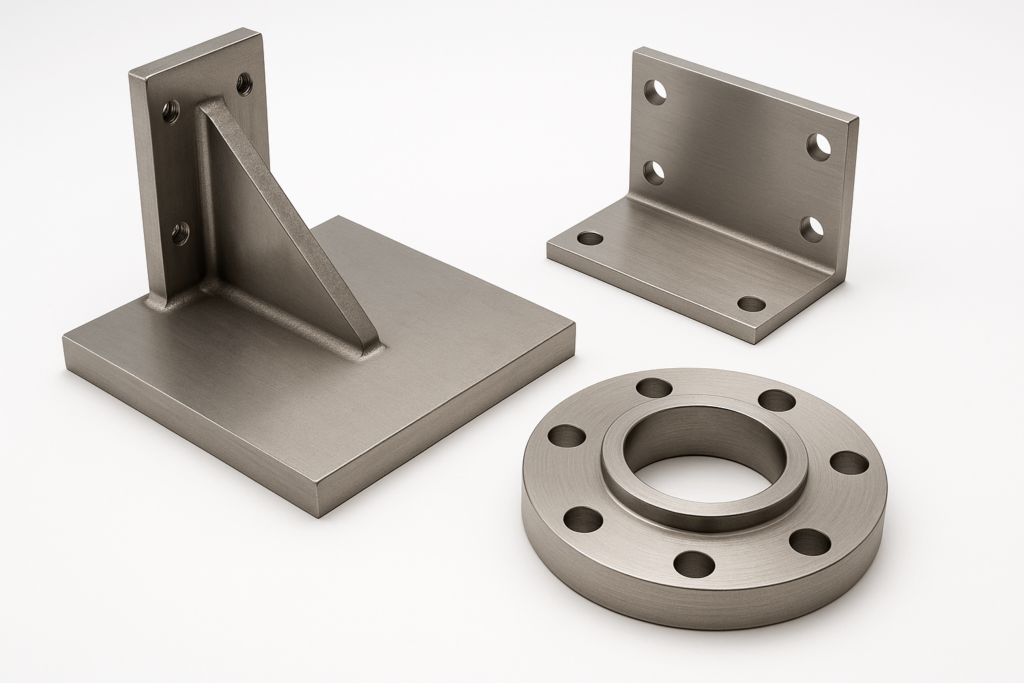

Part 4: Processing Considerations for OEM Stainless Steel Parts

Even the best composition will fail without proper handling. Processing affects surface quality, dimensional tolerance, and corrosion behavior.

YISHANG, as an experienced OEM stainless steel supplier, emphasizes:

- Laser cutting (fiber & CO₂) for sheet metal precision

- CNC machining for detailed parts

- TIG & MIG welding by certified technicians

- Mechanical finishing: grinding, polishing, brushing

- Surface treatments: passivation, powder coating, electro-polishing

Each step is calibrated to preserve the passive film and ensure readiness for industrial assembly.

Part 5: Using PREN to Quantify Corrosion Resistance

The Pitting Resistance Equivalent Number (PREN) provides a numerical way to estimate how well a stainless steel grade resists pitting.

PREN = Cr + 3.3 × Mo + 16 × N

| Grade | Approx. PREN |

|---|---|

| 304 | 18–20 |

| 316 | 23–25 |

| 2205 | 34–38 |

A higher PREN = better protection in chloride-heavy or wet environments.

Conclusion: Matching Composition With Processing = Performance

Stainless steel performance isn’t just about selecting the right grade—it’s about understanding how it behaves during fabrication and in service.

By aligning chemical composition with expert processing, OEM buyers can reduce failure rates, extend product life, and cut long-term cost.

At YISHANG, our engineering team helps B2B clients worldwide turn specifications into stainless steel components that meet ISO 9001 and RoHS standards—delivered on time and built to perform.

FAQ: What B2B Buyers Ask About Stainless Steel

Q1: Why does stainless steel rust?

Surface contamination from machining or handling can disrupt the passive layer. Proper passivation restores it.

Q2: What’s the difference between 304 and 316 stainless steel?

316 includes molybdenum for stronger chloride resistance—preferred for marine, chemical, or food-grade environments.

Q3: Is stainless steel always non-magnetic?

No. Austenitic grades like 304 are non-magnetic. Ferritic and martensitic types are magnetic.

Q4: Which stainless steels are easiest to weld?

304 and 316 offer excellent weldability. Duplex and PH grades need more control during welding.

Q5: Is passivation necessary after machining?

Yes, especially for precision components. It removes embedded iron and re-establishes corrosion resistance.

About the Author

This guide was prepared by the engineering team at YISHANG, an ISO 9001-certified metal manufacturing company based in China. With 26+ years of experience, we specialize in OEM stainless steel fabrication, exporting custom sheet metal components to over 50 countries.

🔧 Capabilities: CNC machining, TIG/MIG welding, laser cutting, polishing, powder coating, and assembly.

📩 Discuss your stainless steel project: Contact Us