Introduction

Cutting stainless steel is a critical operation in high-volume manufacturing. It directly impacts part accuracy, production speed, and cost. For wholesale buyers and sourcing managers, it’s not just about methods—it’s about supplier reliability, repeatability, and technical capabilities.

At YISHANG, we specialize in stainless steel fabrication with over 26 years of experience. Our stainless steel cutting operations support automotive, medical, vending, and energy sectors with consistent output and controlled tolerances. This guide combines engineering insight with procurement relevance, helping you understand how the right cutting process can protect quality and your margins.

Why Stainless Steel Is Challenging to Cut

Unlike mild or galvanized steel, stainless steel resists both heat and mechanical deformation. This strength stems from its alloy composition, especially in grades like 304 and 316. While beneficial in product applications, these traits make cutting more demanding.

Work-hardening is common, especially in 304 stainless. As tools interact with the surface, hardness increases, causing faster wear. This affects blade life, dimensional consistency, and long-term cost. In thermal cutting like laser or plasma, stainless steel’s low thermal conductivity localizes heat, resulting in discoloration and distortion.

That’s why we implement high-performance tooling, optimized feed rates, and cooling strategies. Using coated carbide tooling and CNC systems with real-time compensation ensures consistent part quality, even in batch orders. Our cutting strategies are tailored by grade—whether you’re working with 304 stainless steel yield strength tolerances or demanding 316 stainless heat resistance profiles.

Cutting Thin Stainless Steel Sheet

For 0.5–2.0mm stainless sheet, laser cutting offers the best balance of speed and precision. Our fiber laser cutting machine handles high volumes with minimal thermal distortion. Cuts maintain ±0.15mm tolerance, making them ready for welding or direct assembly.

We support materials like 304 and 316L, with optional polishing and powder coating for finished parts. This process works especially well for electronic enclosures, machine panels, and signage. Our laser cutting table can nest over 60 components per sheet for efficient use.

Where cost is critical, we offer mechanical shearing. While not as precise as laser metal cutting, it’s suitable for non-aesthetic parts. Customers should consider added deburring for these methods. We routinely integrate brushing or vibratory finishing for edge cleanup.

Production Note: Our cutting line processes over 1,200 stainless sheets/month. Each batch includes dimensional reports and optional Ra surface roughness data for powder coated steel finishes.

Cutting Stainless Steel Plate (2mm–20mm)

When cutting thicker stainless plates, the method must align with part function. Plasma cutting is cost-effective for structural brackets and machine frames. However, it introduces a wider kerf and heat-affected zone. Typical tolerances are ±0.4mm, with visible taper.

For higher-end applications—especially involving welding, food contact, or tight assemblies—abrasive waterjet cutting is preferred. This cold-cut method eliminates thermal distortion and offers tolerances within ±0.15mm. It’s commonly used for CNC base plates, panels, and support flanges.

YISHANG uses nesting software to reduce waste by up to 20%. On high-value alloys, scrap optimization directly saves procurement cost. We also monitor cut quality per ISO 9013 classifications and perform edge scans for first-article approval.

Buyer Tip: Be sure to specify edge quality requirements (grind finish vs raw) during RFQ to avoid rework delays.

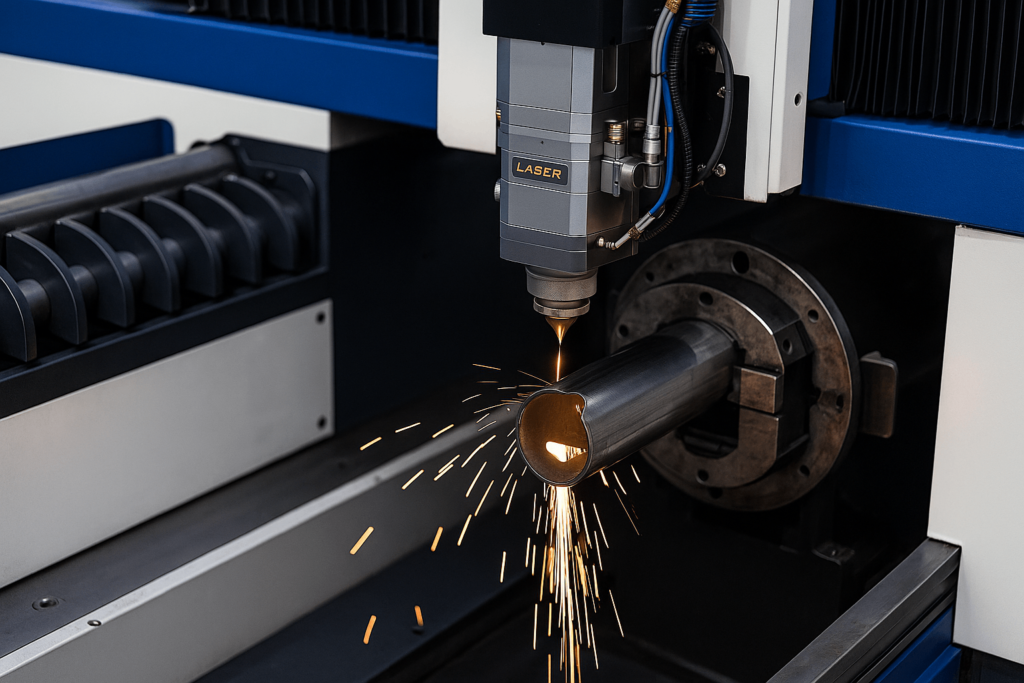

Tube and Pipe Cutting: Accuracy Without Deformation

Laser tube cutting is one of our most requested services. YISHANG’s CNC tube laser cutting line accommodates round, square, and oval profiles up to 120mm OD. This ensures edge integrity and precise lengths for welding or component insertion.

Thin-walled tubes under 1.5mm require mandrel support to prevent ovalization. Our machines also enable slotting, beveling, and perforations in a single cycle. These operations are common in display fixtures, exhaust systems, and vending hardware.

For sanitary or hydraulic applications, orbital cutting provides burr-free results. Combined with polishing or passivation, this method ensures internal cleanliness required in food and pharma systems.

Performance Benchmark: We supply over 8,000 linear meters of stainless tube/month with cut repeatability within ±0.2mm. Each lot passes bore visual checks and dimensional verification.

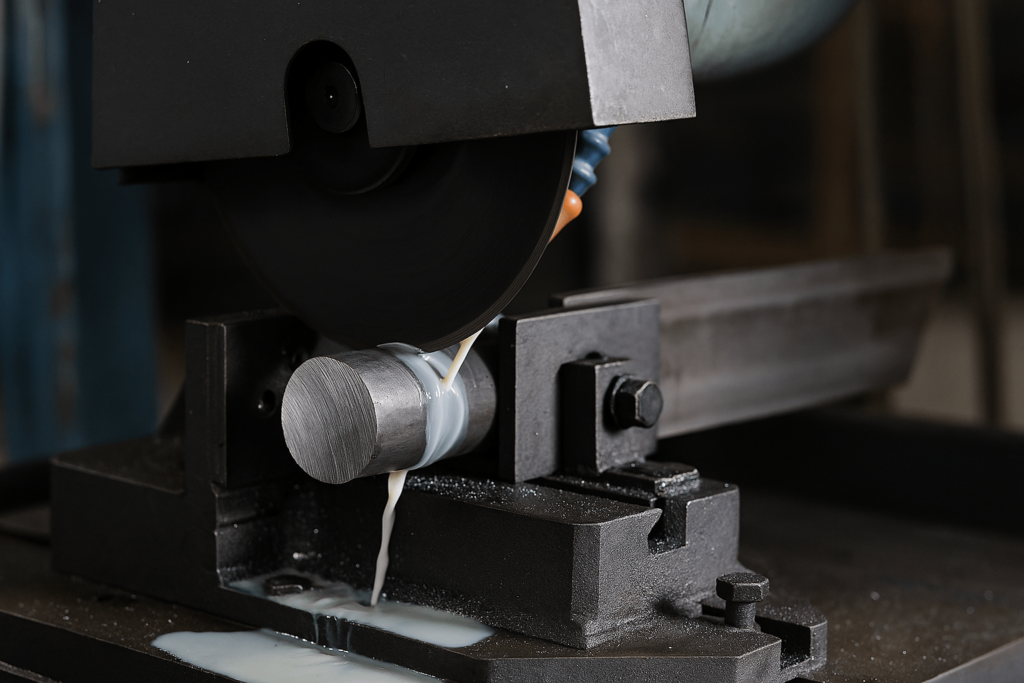

Cutting Rods, Flats, and Angles

Solid bar and angle profiles require rigid clamping and efficient feed systems. Cold saws offer the flattest, most accurate cut surface. These are ideal for fasteners, bracing plates, and CNC blanks. Band saws are used where volume is high but surface finish is not critical.

We use coated saw blades with mist lubrication, prolonging tool life and minimizing discoloration. For angles, dual-head machines cut both legs simultaneously to prevent warping.

Some customers request ready-to-assemble parts. In such cases, we offer chamfering and end-face squareness inspection. For MRO and OEM buyers, this means reduced internal processing and lower defect rates.

Output Example: 12,000 rods/month, with SPC control charts available on request. Stainless grades: 304, 316, 303.

Common Problems and How We Solve Them

Edge Burrs: Caused by tool wear or vibration. We apply post-process brushing or electropolishing based on customer specs. In 2023, 96.3% of all our stainless orders required no further edge refinement.

Part Warping: Common in laser cutting of thin or unsupported sheets. We solve this using vacuum clamping, low-pass laser cycles, and flatness checks per DIN EN ISO 13920.

Dimensional Variability: Prevented by closed-loop CNC calibration. Across five CNC platforms, we use laser interferometry for position correction every 10 cycles.

Certifications: All stainless parts come with ISO 9001 quality backing, and we offer EN 10204 3.1 material certificates on request.

Technical Capabilities You Can Trust

YISHANG is not just a stainless steel laser cutting supplier—we are your fabrication partner. We handle laser cutting materials like 304/316, brass, aluminum, and galvanized steel with full traceability.

Our advanced laser cutting precision systems operate with 5-axis motion, allowing bevel cuts and compound angles. We support laser pipe cutting, cutting copper on laser, and even laser cutting design consultation.

Other services include:

Powder coating for stainless steel and aluminum

Post-cut forming steel sheet and welding

Assembly, labeling, and kitting before shipment

Capacity Snapshot:

Sheet: 1,200 pcs/day

Tube: 400 pcs/day

Rod: 600 pcs/day

MOQ: 50 pcs / model

Lead time: 5–10 working days for repeat orders

FAQs from Buyers (Answered Briefly)

Can you cut 304 and 316 stainless steel? Yes. Most of our monthly volume is 304/316 stainless. We maintain separate tool profiles for each grade.

What is your standard tolerance? ±0.15mm for laser cutting, ±0.2mm for tube and bar. Specific tolerance requests can be reviewed.

Can we get samples or FAI? Absolutely. Samples within 3–5 days. First-article inspection (FAI) is included for most tooling setups.

Do you offer additional finishing like powder coating or polishing? Yes. We offer powder coated steel finishes, brushing, and satin polishing in-house.

Can we use your CAD for cutting optimization? Yes. We assist with cad geometry cutting tool CAD conversion and nesting layouts.

Customer Case Studies

Case Study 1: Stainless Laser-Cut Frames for Medical Equipment

A medical equipment manufacturer in Germany approached YISHANG to supply laser-cut stainless steel frames for diagnostic machines. These required high flatness, ±0.15mm tolerance, and burr-free edges ready for cleanroom assembly.

Challenge: Parts had to be clean-cut with no discoloration, conforming to ISO 2768-m tolerances and compatible with powder coating.

Solution: We used precision fiber laser cutting on 304 stainless with post-process brushing and CMM inspection. Over 2,500 units were delivered within 4 weeks, with 0% rejection rate across three batches.

Case Study 2: Tube Laser Cutting for Retail Display Systems

A U.S.-based retail fixture wholesaler required 12,000 stainless steel tubes with slotting and angle cuts for modular display racks. The customer needed laser cutting with tight repeatability and chamfered edges for easy assembly on-site.

Challenge: Multiple cut angles and slot dimensions had to be held within ±0.2mm, and production had to complete within 12 working days.

Solution: YISHANG’s CNC laser tube cutting machine processed 1,000+ tubes/day. We applied internal mandrel support to prevent deformation, performed 100% slot position checks, and offered full part labeling by SKU. All shipments arrived DDP to the U.S. warehouse.

Conclusion

Whether you need precision laser cutting for 304 stainless enclosures or orbital tube cutting for hygienic assemblies, YISHANG delivers consistent quality at industrial scale.

We combine accurate laser cutting with machining, deburring, and packaging—all in-house. With technical staff fluent in drawing review and project scheduling, our team ensures your purchase is delivered correctly, not just cut correctly.