Why Stainless Steel Finish Matters in Global B2B Sourcing

For B2B sourcing professionals and bulk buyers, stainless steel surface finish is more than just a design detail—it affects corrosion resistance, hygiene control, product lifespan, and regulatory compliance. Each of these factors has direct cost implications in production and after-sale service.

Buyers working across global supply chains must ensure finish consistency, especially where roughness (Ra) affects certifications or audit readiness. Defining surface finish clearly from the start helps prevent shipment rejection, rework delays, or mismatched batch deliveries. Whether sourcing sanitary enclosures or brushed retail panels, specifying the right finish up front ensures better outcomes.

From Ra to Reality: Understanding Surface Roughness Metrics

When preparing your RFQ, be sure to specify not only the finish code, but also its equivalent Ra value and visual tolerance. For guidance, see our tips on how to specify stainless steel finish in RFQ.

Surface roughness—often expressed as Ra or Roughness Average—is a key indicator for stainless steel surface quality. It measures the average vertical deviations of a surface, commonly in micrometers (µm) or microinches.

Understanding how to measure the roughness of a surface is essential for buyers specifying finishes. Common tools like profilometers or contact stylus systems help determine Ra values. However, Ra alone doesn’t define functionality. Two finishes with the same Ra can differ in cleanability and corrosion resistance depending on how they are produced—mechanically, chemically, or through electropolishing.

| Application | Ra (µm) Max | Regulatory Relevance |

|---|---|---|

| Food-Grade Surfaces | ≤ 0.8 | 3-A, FDA, EU 1935/2004 |

| Medical Instruments | ≤ 0.4 | ISO 13485, ASTM F86, ISO 10993 |

| Decorative Uses | ≤ 1.2 | Visual consistency, durability |

It’s also important to know how Ra relates to traditional machine finishes: for example, a 125 surface finish (or 125 microinch finish) is equivalent to roughly 3.2 µm, and a 32 surface finish is about 0.8 µm. These references help align global standards with U.S. machine specs like 125 finish or 32 finish in production drawings.

The Finish Spectrum: Practical Options for B2B Buyers

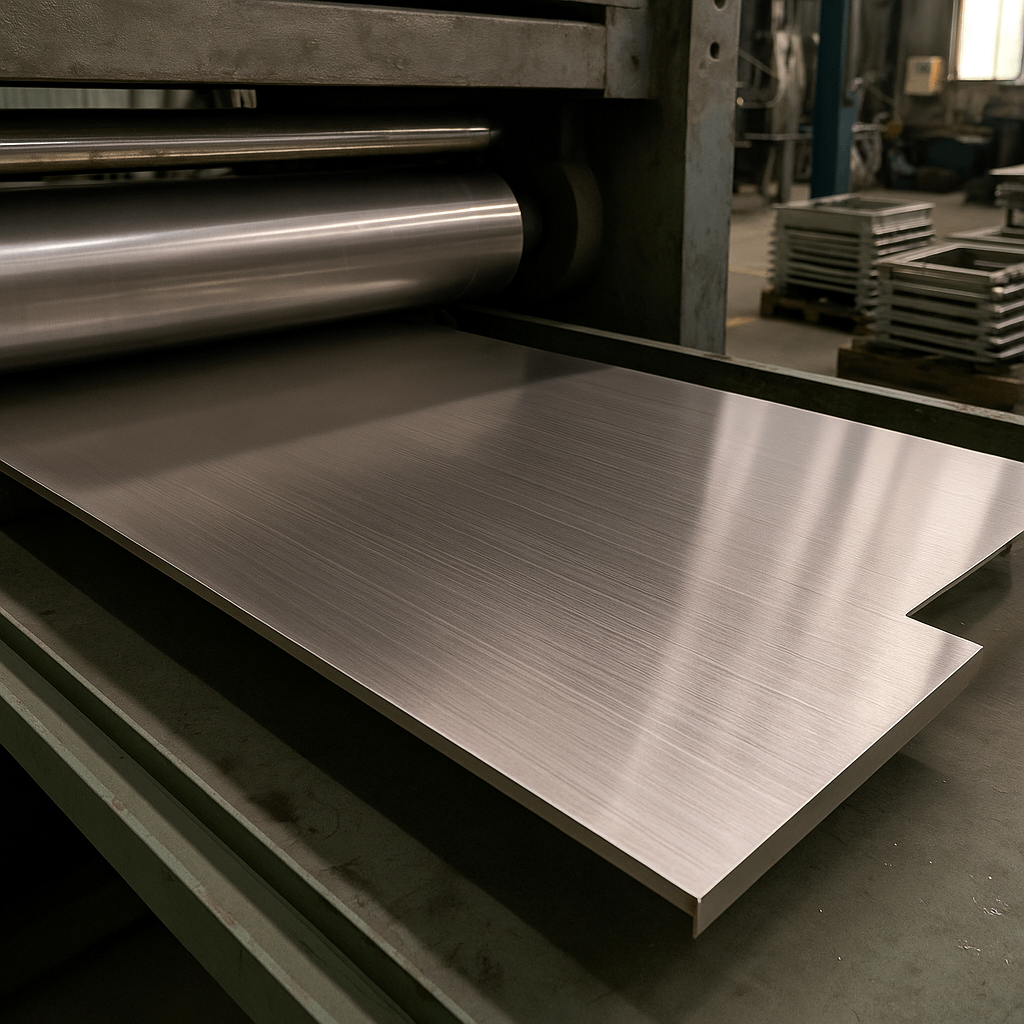

Mill Finishes (2B, 2D)

Mill finishes are the result of basic hot or cold rolling with no additional treatment. They offer minimal reflectivity and are typically used where appearance is secondary to strength and cost.

Often chosen for inner cabinet walls, structural frames, and concealed support parts due to their practicality and low reflectivity.

They match the 250 surface finish equivalent and serve well in basic enclosures where aesthetics are not critical.

Brushed / No.4 Finish

This finish is created by polishing with abrasives to produce a linear grain appearance. It reduces surface glare while offering improved fingerprint resistance and a modern look.

Commonly used in appliance surfaces, kiosks, and commercial display racks where aesthetics and durability intersect.

For aluminum, an aluminium brushed finish offers a similar aesthetic. Procurement teams often select this for high-visibility products requiring moderate scratch resistance.

Mirror / No.8 Finish

This is a highly reflective, non-directional finish achieved through successive polishing stages. It eliminates surface imperfections and produces an almost flawless visual appeal.

This finish is preferred in luxury interior designs, clean medical cabinetry, and upscale signage where clarity and visual impact matter.

Maintaining consistency and proper packaging is essential, as mirror finishes are prone to scratches. For high-traffic areas, additional coating or lamination is often required.

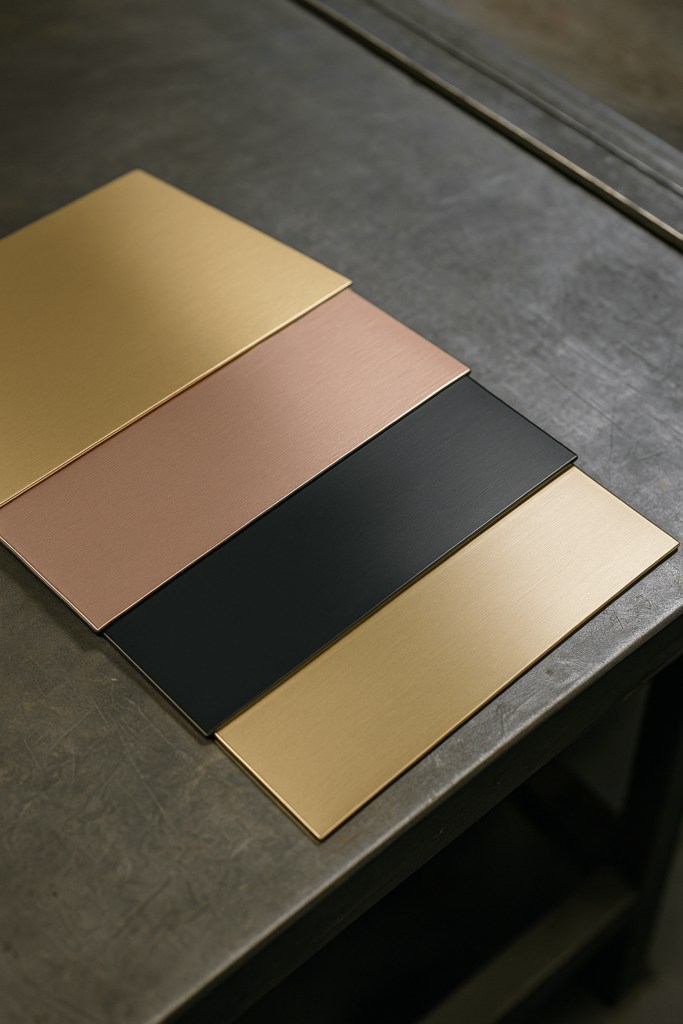

PVD & Colored Finishes

PVD (Physical Vapor Deposition) applies a vaporized metal layer onto the surface, adding color, hardness, and corrosion resistance. What is PVD finish? It’s a non-electrolytic process used to enhance durability and color options without increasing Ra values.

Procurement teams select this for high-end architectural elements and retail display systems demanding both appearance and longevity.

This category is also evolving. Some manufacturers now combine PVD base layers with powder coated surface protection to achieve both aesthetic appeal and weather durability—especially in retail and transport infrastructure. This aligns with broader trends like the shift toward VOC-free coatings and rising REACH compliance expectations.

Textured / Embossed Finishes

These finishes are mechanically or chemically produced to create patterns or textures such as leather, linen, or checker. They reduce glare and increase scratch concealment.

Suitable for commercial counters, facade treatments, and enclosures where texture helps mask wear or impact.

Refer to a bead blast surface finish chart or compare 2B and No.4 finishes to better assess functional and aesthetic suitability when evaluating suppliers.

Functional Coatings: Anti-Fingerprint, Hydrophobic Layers

These treatments reduce fingerprint smudging and improve ease of cleaning. They are typically applied on top of No.4 or PVD finishes.

Often applied in electronics cases, interactive terminals, and sterile enclosures for their resistance to smudging and ease of cleaning.

Anti-fingerprint finishes are now often combined with nanocoatings or oleophobic layers. This integration extends cleanability and product life—particularly valuable in high-touch commercial and medical products. Anti-smudge performance is also a procurement differentiator in sectors like EV charging stations and interactive kiosks.

Regulatory Relevance: Aligning Finishes with Market Compliance

For international buyers, finish choice isn’t just a performance decision—it’s a compliance gatekeeper. In food, pharma, and cleanroom industries, improper finishes can result in failed audits or rejected shipments.

Food Contact Products: Ra ≤ 0.8 µm (or 32 surface finish in microinches). Must resist residue accumulation. Certifications may include 3-A, NSF, or equivalent.

Medical Devices: Finishes like 16 surface finish (or 0.4 µm) required. Electropolished parts meet ISO 13485. Biocompatibility testing often uses 8 Ra surface finish benchmarks.

Public Infrastructure: Require anti-glare and tactile feedback. For example, Class A surface finish may be needed for decorative panels near touchable zones.

YISHANG supports buyers with documented test reports including 125 Ra surface finish validation or custom roughness sampling per batch. For applications like food-grade enclosures, we can recommend what finish is best for food-grade enclosures based on region-specific regulations and industry expectations.

Suppliers without proper documentation may trigger customs delays or QA disputes. Request bead blasted finish samples or 32-125 surface finish photos where necessary.

Finish Strategy by Use Case: Balancing Compliance and Cost

Sourcing teams must connect finish with functional performance—not visual preference. Below are practical pairings for procurement planning:

| Industry | Preferred Finish | Notes |

| Medical Equipment | Electropolish / No.8 | Must meet 8 Ra surface finish standard |

| Food Processing | No.4 / 32 finish | Cleanability, global compliance |

| Retail & Display | PVD + Anti-Fingerprint | Touch durability + branding layer |

| Urban Architecture | Bead Blast / Embossed | 40 surface finish / 63 surface finish range |

| Machine Frames | 2B / Pickled | Cost-effective, fits 125 machine finish standard |

If you’re dealing with aluminum parts, coordinate with suppliers for aluminum surface finish specs, as Ra values differ slightly.

Procurement teams often reference 3.2 surface finish in inches (≈125 µin) when comparing RFQs. Confirm that equivalent ISO or ASME specs are matched.

Buyer-Side Risks and How to Avoid Costly Misalignment

Miscommunication in finish terminology remains one of the top reasons for rejected shipments. Stating “brushed finish” without grit, Ra value, or reference standard opens the door to interpretation.

Be specific: for example, request “125 rms surface finish” rather than just “smooth finish.” If necessary, request a 125 surface finish example or a finish coupon.

Another trap is under-specifying which surfaces are cosmetic (Class A) versus structural. This leads to issues during assembly or post-fabrication review. Smart procurement includes clearly labeled drawings with callouts like 32 ra surface finish or 3.2 ra surface finish.

YISHANG offers metal finishing services with inspection protocols tailored for bulk OEM orders, supporting consistency across batches. Our team can also walk you through the benefits of electropolishing stainless steel versus other fine finishing methods for critical sanitary or pharmaceutical use.

What’s Next: Future-Proofing with Functional Finishes

With increasing regulatory scrutiny and user expectations, functional finishes are gaining traction:

Eco Coatings: Water-based and VOC-free, support RoHS and REACH.

Laser Etching: Enables anti-bacterial surface creation without chemical layering.

Self-healing Coatings: Minimize visual wear for long-lifecycle parts.

Digitally Patterned Surfaces: Combine brand expression with user interactivity.

B2B buyers investing in long-term sourcing benefit from exploring new-generation metal finishing solutions. A well-maintained surface finish comparison chart supports internal audits and helps unify sourcing criteria across regions, especially when balancing aesthetic and environmental requirements.

Conclusion: Source the Right Finish, Not Just the Right Material

In stainless steel sourcing, finish quality impacts certification, durability, and customer satisfaction as much as the base material itself. For bulk buyers, a misaligned surface spec can mean rework, delays, or even regulatory rejection.

Whether you’re referencing 125 rms surface finish or comparing 3.2 ra surface finish equivalents across suppliers, your choices must link directly to downstream usage. Finishes aren’t visual extras—they’re performance enablers.

YISHANG supports global B2B procurement with batch consistency, test data, and custom finishing capabilities. From food-grade housings to branded PVD exteriors, we help you ensure precise, batch-consistent results across high-volume orders.