Introduction: Why Laminated Stainless Steel Sheets Are a Strategic Asset for Global Buyers

The role of laminated stainless steel sheets has significantly evolved. Once considered primarily decorative, they now represent a critical material choice in heavy-duty OEM systems, high-spec enclosures, modern infrastructure, and international manufacturing ecosystems. Their appeal lies not only in appearance but in performance, reliability, and regulatory alignment — key concerns for global wholesale procurement professionals.

In this article, we move beyond surface-level definitions. We break down what truly matters to B2B buyers: technical capability, material traceability, compatibility with automation, and supplier dependability. Every section is designed to offer real sourcing value for importers, contractors, and OEMs who require laminated stainless steel products that deliver more than just shine.

The Technical Foundation of Laminated Stainless Steel Sheets

Lamination Technology and Core Construction

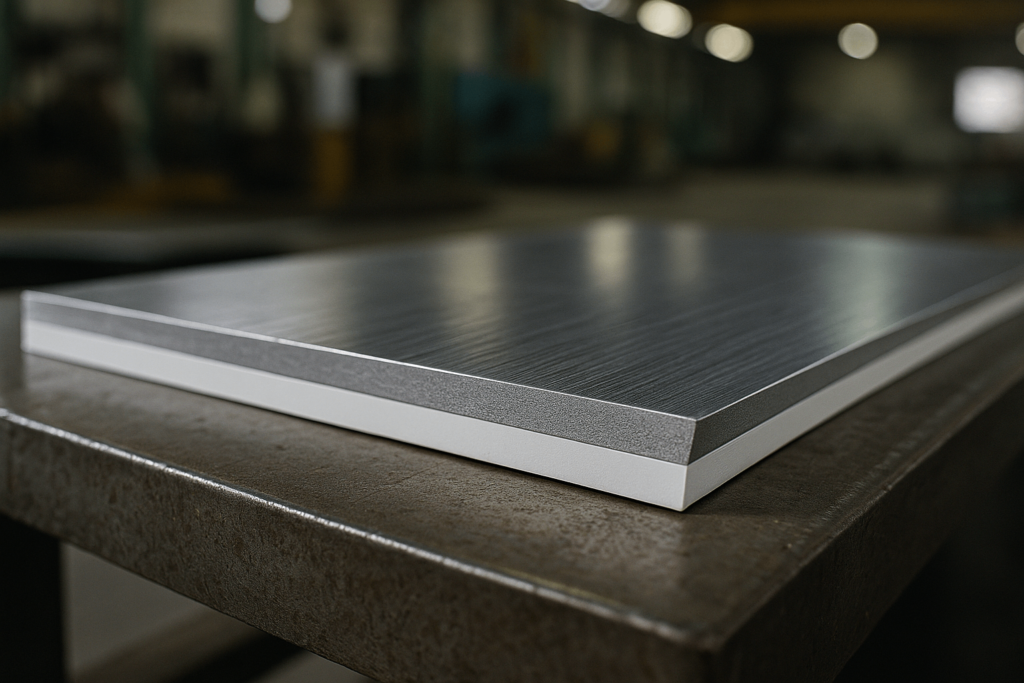

Laminated stainless steel is built from a stainless substrate (typically grades 201, 304, or 316) bonded with functional or aesthetic layers such as PVC film, PVD coatings, or embossed sheets. The lamination process uses high-pressure rollers, thermal fusion, and specialized adhesives — ensuring a strong, uniform bond that resists delamination during cutting, welding, or forming.

Depending on your end application, lamination options vary:

- Decorative film overlays: Enhance branding, mimic wood or stone, or deliver unique textures.

- PVD titanium coatings: Strengthen surface hardness and color retention.

- Functional vinyl layers: Add anti-fingerprint, anti-bacterial, or UV resistance properties.

These layers are not cosmetic—they impact maintenance costs, longevity, and compliance with hygienic or safety regulations in industries such as medical devices and food processing.

Key Stainless Grades and Their Applications

| Grade | Properties | Typical Use Cases |

|---|---|---|

| 201 | Cost-effective, low nickel | Retail panels, signage, indoor décor |

| 304 | High corrosion resistance, good weldability | Transit systems, control boxes, medical equipment |

| 316 | Marine-grade, chloride-resistant | Coastal installations, chemical enclosures |

Procurement Tip: Don’t assume higher grade means better result — material selection should match operating environment and structural load expectations. Over-specifying leads to inflated cost.

Functional Finishes for Industrial Demands

Surface finish is not just aesthetic—it determines durability, cleanability, and reflectivity. Laminated stainless sheets can be:

- Hairline or brushed: Ideal for elevators and kiosks — hides fingerprints, durable for public use.

- Mirror polish: Used in retail, high-end hospitality, and clean rooms.

- Embossed or etched: For slip-resistance in flooring or tactile branding.

Top-tier laminations may combine multiple finishes with nano or ceramic coatings, extending wear cycles and meeting LEED/green building certifications.

Application Scenarios: Why Wholesale Buyers Choose Laminated Stainless Steel

Precision Electronics and Industrial Enclosures

Laminated stainless steel is widely used in manufacturing:

- Battery and energy storage cabinets

- NEMA/IP-rated electronic enclosures

- Electrical distribution boxes for EV charging or solar systems

What matters to these industries:

- Flatness and gauge consistency for CNC cutting

- Heat tolerance for enclosure assembly

- Reliable grounding pathways post-coating

Procurement needs in these sectors often focus on tight tolerances, custom perforations, and third-party inspection availability.

High-Durability Requirements in Public Infrastructure

Subways, airports, hospitals, and public terminals use stainless steel laminates for:

- Wall cladding and elevator wraps

- Wayfinding and signage panels

- Vandal-resistant kiosks and ticket machines

Laminated stainless products used in these areas must pass:

- Flame spread and smoke development ratings

- Anti-graffiti and easy-clean surface tests

- ISO 9227 salt spray and ASTM B117 humidity trials

Custom embossing also allows for ADA tactile compliance or anti-slip flooring in wet zones.

Branding Through Materials in Retail and Hospitality

Retail chains and hotel groups seek consistent finishes across franchises and regions. Laminated stainless steel achieves:

- Visual cohesion across geographies

- Lower refurbishment cost through long-life materials

- Design flexibility (colors, textures, laser etching)

Examples: Gold mirror PVD in luxury boutiques, black etched finishes in automotive showrooms, brushed stainless for commercial furniture.

Our factory provides digital mockups to match your architectural palette and replicates finishes with batch-to-batch consistency.

Streamlining Procurement: Customization and Logistics for Global Buyers

Small MOQ and Pilot Production Compatibility

Whether you’re sourcing for a regional project or testing a product line, we adapt:

- MOQ as low as 30–50 sheets

- Rapid prototyping with finish matching

- Digital pattern proofing for approvals before mass run

Our production system is configured for small-lot precision and large-lot efficiency, ensuring flexibility without compromise on quality.

Efficient Lead Times and Shipping Assurance

Lead times range from 12 to 20 days depending on custom requirements. Export-friendly packing and documentation include:

- PE film + kraft wrapping + metal pallet

- Labeling per destination country

- RoHS/REACH declaration and mill test reports

We offer:

- FOB, CIF, DDP terms

- Support for mixed container load

- End-to-end logistics visibility

Shipping labels can be branded or neutral per your OEM/ODM requirements.

Certifications and Third-Party Readiness: What Buyers Need to Know

Global Certification Alignment

We ensure readiness for international sourcing compliance:

- ISO 9001 quality control system

- RoHS / REACH for electronics and public projects

- CE/UL documentation upon request

Test reports can include:

- Hardness (HV)

- Peel strength of lamination

- Thickness deviation within ±0.03 mm

External Testing and Audit Support

We work with SGS, TÜV, and BV for third-party verifications. Whether it’s salt-spray testing, cross-cut adhesion validation, or material traceability checks — your audits are supported with full documentation.

All documents can be pre-formatted for public tender requirements or vendor portal submission.

Choosing the Right Specification for Your Market

Here’s how to think through sourcing strategy:

| Application Environment | Recommended Grade & Finish | Notes |

|---|---|---|

| Indoor Furniture | 201 + decorative vinyl | Cost-effective, light load |

| Urban Kiosks | 304 hairline + anti-fingerprint | High-touch and outdoor compatible |

| Marine Equipment | 316 + PVD laminate | Chloride exposure resistant |

| Transit Projects | 304 brushed + embossing | Fire and abrasion tested |

We recommend submitting BOMs or DWG files for pre-sourcing evaluation — our engineers will simulate performance with your environment in mind and avoid over-specification.

Conclusion and Next Steps: Strategic Sourcing Starts Here

From industrial enclosures to branded commercial fixtures, laminated stainless steel sheets combine strength, consistency, and aesthetic range. But sourcing them successfully requires more than just choosing a finish — it’s about technical match, documentation readiness, and vendor reliability.

At YISHANG, we align engineering with export logistics and compliance. Our clients across 50+ countries trust us for:

- Controlled lamination consistency

- Flexible MOQ with batch scaling

- Certifications and audit support

Let us support your material strategy — whether you’re prototyping for a new market or standardizing across global sites.

RFQ & Technical Support (Optional CTA)

Contact our team for:

- Technical data sheets and downloadable specs

- Custom pricing by sheet size or project batch

- Finish samples and mockup service