Introduction: Beyond Aesthetics—A Commitment to Performance

For wholesale buyers, architects, and contractors sourcing high-performance stainless steel trim in bulk, material selection is more than a technical choice—it’s a decision that affects long-term durability, project profitability, and client satisfaction. An incorrect grade of stainless trim can trigger costly warranty claims, while inconsistent tolerances may lead to installation delays and reputational risks.

This guide is engineered for procurement professionals who require more than surface-level answers. It delivers verifiable technical data, field-proven fabrication methods, and installation protocols—empowering you to specify, source, and apply custom stainless steel trim profiles with absolute confidence.

Part 1: The Science of Specification—Mitigating Risk Through Material Intelligence

Understanding stainless steel at the material science level gives B2B buyers a competitive edge in both project performance and lifecycle cost. Below, we unpack how to select the right grade, surface finish, and coating system to meet environmental and operational realities.

304 vs. 316 Stainless Steel: Which Grade Is Right for Your Project?

The most critical choice begins with grade selection. Although 304 and 316 stainless steel may appear identical, their corrosion resistance, especially in chloride-rich environments, differs significantly due to alloy composition—primarily molybdenum in 316.

| Element | Grade 304 | Grade 316 | Role in Performance |

|---|---|---|---|

| Chromium (Cr) | 18.0–20.0 | 16.0–18.0 | Forms the passive protective oxide layer |

| Nickel (Ni) | 8.0–10.5 | 10.0–14.0 | Improves ductility and corrosion resistance |

| Molybdenum (Mo) | – | 2.0–3.0 | Critical for chloride resistance |

| Carbon (C) | ≤ 0.08 | ≤ 0.08 | Affects weldability |

| Property | Grade 304 | Grade 316 |

|---|---|---|

| Tensile Strength (psi) | ~73,200 | ~79,800 |

| Yield Strength (psi) | ~31,200 | ~34,800 |

| Hardness (HRB) | 70 | 80 |

Use 316 stainless steel for:

- Coastal construction within 5 km of shorelines

- Locations exposed to road salt or de-icing agents

- Food-grade and chemical industrial settings

Use 304 stainless steel for:

- Interior or low-humidity zones

- Budget-conscious, low-exposure environments

💡 Tip: Always specify 316L for welded applications to minimize carbon-induced corrosion.

Does Surface Finish Affect Durability? Yes—and Here’s How

Beyond visual appeal, finish roughness (Ra value) directly influences a surface’s susceptibility to corrosion. Polished stainless surfaces allow fewer chloride deposits to adhere.

| Finish Type | Typical Ra (µm) | Corrosion Performance | Application Note |

|---|---|---|---|

| Mirror (No. 8) | ≤ 0.2 | Excellent | Ideal for coastal, marine, and public spaces |

| Brushed (No. 4) | 0.5–0.8 | Moderate | Common for interiors and non-critical zones |

| Bead-Blasted | ≥ 1.0 | Fair | Aesthetic only, requires sealing or coating |

✅ Recommended: For all exterior projects within marine zones, specify an Ra ≤ 0.5µm with passivated welds to meet ISO 9223 corrosion categories.

PVD Coating for Stainless Steel Trim: Pros, Limitations, and Applications

Physical Vapor Deposition (PVD) is a vacuum-based technique that applies a microscopically thin, color-stable coating to stainless steel. It’s more durable than painting or powder coating, making it suitable for decorative trims in commercial interiors, hotels, elevators, and branded retail fixtures.

- ✅ Scratch-resistant, fingerprint-tolerant

- ✅ 10x harder than conventional coatings

- ⚠️ Not suitable for exterior marine environments

🧼 Maintenance Tip: Clean only with soft cloths and pH-neutral detergent—abrasives degrade the PVD layer.

Part 2: Installation and Fabrication—Where Projects Are Won or Lost

Your trim is only as good as its cut and install. YISHANG’s ISO 9001 and RoHS-compliant manufacturing process ensures consistent output, while our engineering team provides OEM support for edge profile customization, adhesive compatibility testing, and project-specific tooling.

How to Cut Stainless Steel Trim Without Losing Corrosion Resistance

Improper cutting generates heat-affected zones (HAZ) that weaken corrosion resistance. Avoid high-friction tools.

| Method | Recommended? | Notes |

|---|---|---|

| Cold Saw (Cermet) | ✅ Yes | Clean, burr-free, no HAZ |

| Laser Cutting | ✅ Yes | Ideal for precise, intricate designs |

| Angle Grinder | ⚠️ Use with caution | Use INOX disc, multiple shallow passes |

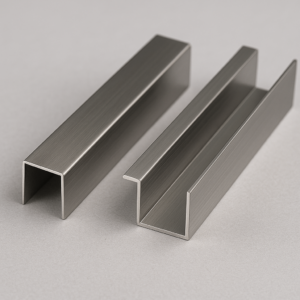

Stainless Trim Profiles: L, T, U and Where to Use Them

| Profile Type | Use Case | Installation Note |

|---|---|---|

| L-Profile | Tile edge trim, wall corners | Set in tile adhesive, leave grout gap |

| T-Profile | Floor-to-floor expansion joints | Use construction adhesive or track mounting |

| U-Channel | Securing fixed glass panels or signage | Seal with silicone, use setting blocks to cushion glass |

🔧 Field Insight: Always apply with fully compatible adhesive for substrate and loading type. YISHANG can assist with adhesive performance verification upon request.

Adhesive Compatibility Matrix for OEM Stainless Trim Installations

| Substrate | Adhesive Type | Note |

|---|---|---|

| Wood | Polyurethane adhesive | Flexible bond, tolerates thermal movement |

| Glass | Two-part epoxy (clear) | High strength, visually clean |

| Tile / Masonry | PU construction adhesive | Excellent grab, weather-tolerant |

| Plastic | Two-part epoxy | Will not bond to PE or PP without specialized primer |

Part 3: Life Cycle ROI—Stainless Steel as a Long-Term Asset

How to Prevent Tea Staining in Coastal Applications

Tea staining (surface discoloration from chlorides) is common in improperly specified coastal trims. Prevention protocol:

- Use Grade 316 or 316L exclusively

- Ensure Ra ≤ 0.5 µm polished finish

- Pickle & passivate all welds (ASTM A967 recommended)

- Design for drainage and minimal water retention

- Establish a rinse-maintenance schedule (every 6–12 weeks depending on location)

Real-World Example: Stainless Trim in a Commercial Restaurant

Case: Ninyas Restaurant, Mexico City

Polished stainless steel wall panels were used in high-contact dining areas. Indirect lighting reflected off the surface to create ambiance. Designers paired U-channel trims with custom LED lighting for edge highlights.

Stainless steel trim was chosen for both its hygienic profile and branding flexibility—an architectural and commercial win.

Stainless Steel vs. Aluminum or Wood Trim: Lifetime Cost Comparison

| Criteria | Stainless Steel | Aluminum / Wood |

|---|---|---|

| Initial Cost | Moderate-High | Low |

| Maintenance | Minimal | Requires sealing/painting |

| Service Life | 30–50+ years | 5–15 years |

| Residual Value | High (recyclable) | Low to none |

Conclusion: Stainless steel may cost more upfront, but for procurement teams managing lifecycle ROI, it delivers unmatched economic performance.

Conclusion: Why Wholesale Buyers Prefer OEM Stainless Steel Trim from YISHANG

YISHANG has over 26 years of fabrication experience across 50+ countries, offering OEM and ODM stainless steel trim solutions for architecture, construction, vending equipment, and commercial interiors. Our factory supports custom profiles, bulk orders, ISO 9001 quality control, and precision CNC fabrication.

📩 Ready to Specify or Source Stainless Trim?

Contact our engineering team to request:

- Free technical consultation

- Custom trim drawings and specifications

- Bulk quote and lead time

👉 Contact YISHANG’s Stainless Fabrication Team Now

Frequently Asked Questions (FAQ)

Q1: What’s the best stainless steel trim for humid environments?

A: Use 316 or 316L grade with a polished surface finish (Ra ≤ 0.5 µm).

Q2: Can I request custom shapes for edge profiles?

A: Yes. YISHANG offers OEM support including custom forming, punching, and cutting.

Q3: Does stainless trim discolor over time?

A: Only in aggressive chloride environments without proper specification. Use marine-grade and perform regular rinsing.

Q4: Do you ship internationally?

A: Yes, we export to over 50 countries and can provide international logistics support.

Q5: What’s your MOQ for OEM trim?

A: Minimum order quantity varies by profile complexity, but typically starts from 300 linear meters.