In today’s global industrial supply chains, precision is not a luxury—it’s a necessity. For wholesale stainless steel tube buyers, even a slight misstep in dimensional specifications can lead to serious consequences: rejected shipments, unusable inventory, or costly project delays. These problems often originate from a basic yet common confusion between two seemingly similar terms: pipe vs tube.

Understanding this distinction is the first—and arguably most critical—step in correctly sourcing stainless steel tubing. This guide is built for engineering buyers, project managers, and technical procurement professionals who want more than definitions. It’s a project-oriented blueprint that shows you how to select tubing dimensions based on actual performance needs, whether your application involves structural integrity, pressure containment, precision fit, or sanitary use.

We’ll walk through the logic used by experienced sourcing teams and engineers. Along the way, you’ll gain practical insights and tools to ensure that your tubing not only meets technical drawings but also supports the functionality, durability, and compliance standards required in real-world applications.

Whether you’re purchasing for OEM fabrication, industrial automation, or cleanroom assembly, this guide will help you avoid costly mistakes—and specify stainless steel tubing right the first time.

I. Start Here: The One Decision That Defines Your Entire Project

Before diving into charts or catalogs, there’s one essential question that will guide all your stainless steel tubing decisions: Is your application transporting something (like fluids or gases) or constructing something (like frames or components)? This single distinction sets the course for how you’ll measure, specify, and source tubing.

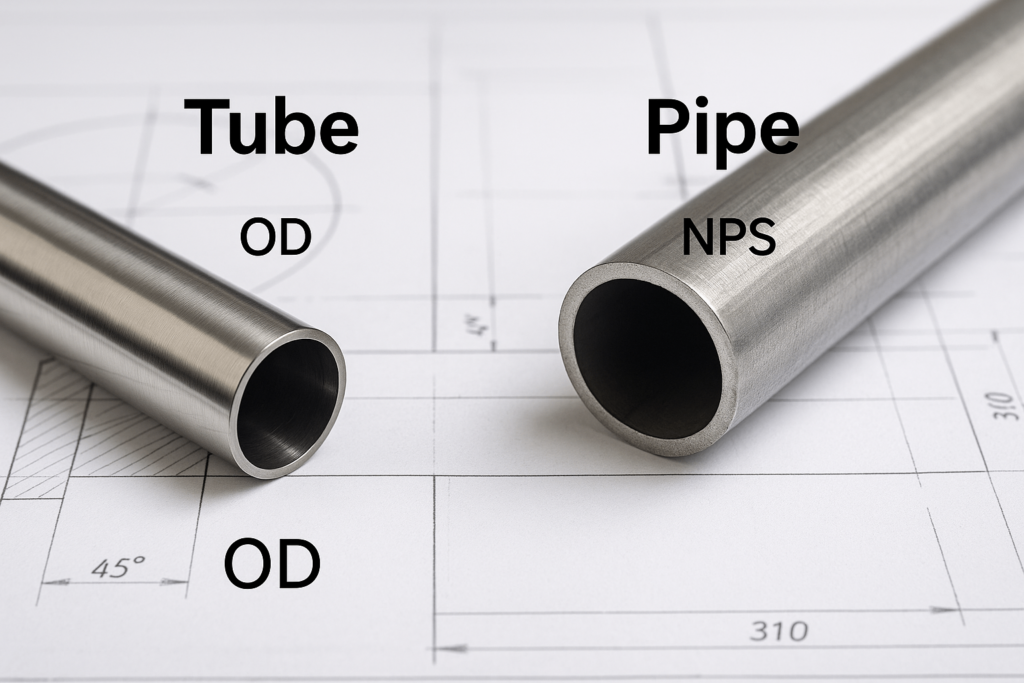

The critical difference between pipe and tube lies in how they are measured, which is inherently tied to their intended function. Pipes are used for transporting fluids, so their sizing revolves around internal capacity. That’s why they follow the Nominal Pipe Size (NPS) standard—an approximate system based on inside diameter (ID).

Tubes, by contrast, are used for structural and mechanical purposes. For these applications, outside dimensions are what matter—and they’re measured precisely. Stainless steel tubes are specified by their exact Outside Diameter (OD), making them suitable for load-bearing, frame-building, and precision fittings.

Choosing between pipe and tube isn’t just semantics. It influences the measurement standard (NPS vs OD) you’ll use, the tolerance levels you’ll require, the fittings and connections involved, and even the project budget and compliance risks.

💡 Long-Tail Tip: This distinction is one of the most searched questions by engineering procurement professionals. Phrases like “OD vs ID in stainless tubing” or “pipe vs tube for industrial applications” are great anchors for organic traffic and should appear naturally in your copy or linked FAQs.

Ultimately, deciding between pipe and tube is the foundation of a successful stainless steel sourcing strategy. Get this right, and every downstream decision—from wall thickness to surface finish—will align with your project goals.

II. The Application-Driven Sizing Matrix: Match Your Goal to the Right Dimensions

Once you’ve identified that tubing—not piping—is the right choice, the next step is to align your size selection with the functional goal of the application. Rather than choosing dimensions arbitrarily, savvy B2B buyers consider the primary performance requirement of the end use. This helps prevent underperformance or overengineering—and reduces waste in both cost and material.

Goal 1: Structural Integrity — “I need it to be strong and not bend.”

When building frames, racks, or architectural features, structural stiffness is critical. Here, stainless steel tubing strength—especially resistance to bending—takes center stage.

While wall thickness plays a role, the driving factor is the Moment of Inertia (MOI), an engineering principle that quantifies bending resistance. Tubes with different shapes (round, square, rectangular) perform differently under load—even at the same weight.

This is why rectangular and square tubes often outperform round tubes in static structures. A rectangular tube, properly oriented, can exhibit a “strong axis” that significantly resists deflection.

💡 Pro Tip: Recommend rectangular tubing in place of heavier square tubes where appropriate. They can offer equal or better performance with lower weight and cost.

For structural goals, prioritize the following specs:

- Shape: Square or rectangular

- Height and width: For moment arm calculations

- Wall thickness: Commonly listed by gauge or mm

Always verify load capacity through engineering support when used in safety-critical systems.

Goal 2: Pressure Containment — “I need it to hold pressure without failing.”

In fluid transport, chemical injection, or hydraulic systems, pressure rating is paramount. Stainless tubing’s ability to resist internal pressure depends on:

- Wall thickness (t)

- Outside diameter (D)

- Material strength (S)

Use Barlow’s Formula to estimate burst pressure:

$P = (2 × S × t) / D$

Where:

- P = Internal pressure in PSI

- S = Allowable stress of material (e.g., 30,000 PSI for 304 stainless)

- t = Wall thickness (inches)

- D = Outside diameter (inches)

✅ Example: A 1.000″ OD tube with 0.065″ wall in 304 stainless has a burst pressure of ~3,900 PSI. Applying a safety factor of 4 yields a working pressure of ~975 PSI.

When pressure containment is the goal, focus on:

- OD and wall thickness pairings

- Material grade and its stress limits

- Safety factors mandated by the application

Goal 3: Precision Fit & Mechanical Function — “I need it to fit perfectly with other parts.”

When tubing is part of a moving system, such as telescoping arms, shafts, or precision-guided assemblies, dimensional accuracy becomes essential.

Unlike pipe, stainless tubing is manufactured to precise OD values, often within ±0.005″ or tighter. This ensures a proper press-fit, slip-fit, or welded assembly, especially in automation or mechanical engineering applications.

Why does this matter for you as a buyer? Because tight tolerances reduce rework, improve system performance, and lower defect rates.

Key considerations:

- Exact OD tolerance class (e.g., ASTM A554 H tolerance)

- Roundness and straightness specifications

- Surface finish, if mating with other components

🔧 Sourcing Note: Always request certified tolerance specs or inspection reports if the tube plays a mechanical role in the final product.

Goal 4: Purity & Cleanability — “I need it for a sanitary or high-purity environment.”

In food processing, pharmaceuticals, and biotech, the most critical aspect isn’t dimension—it’s surface hygiene. For these applications, tubes must comply with specific surface finish and cleanliness standards.

Key specifiers include:

- Ra value (surface roughness average)

- Material grade (typically 316L)

- Applicable standards (e.g., ASTM A270, ASME BPE)

Sanitary tubing must be free from surface pits, crevices, or weld contamination, which could harbor bacteria. Electropolished surfaces (e.g., SF4 in BPE) are often required.

📌 Example: A dairy line may call for ASTM A270 tubing with 180-grit finish; a biotech system may need ASME BPE SF1 or SF4.

When hygiene is key, specify:

- Finish designation (e.g., SF1, SF4)

- Ra requirement (in µm)

- Certifications or documentation of compliance

Each application goal defines what dimensions and characteristics should be prioritized. This functional mindset helps B2B buyers provide more accurate quotes, better technical advice, and stronger supply reliability.

III. The Expert’s Playbook: Avoiding Costly Mistakes When Sourcing Tubing

Matching dimensions to project goals is foundational—but experienced sourcing professionals go further. They proactively identify potential risks that could lead to product failures, project delays, or increased costs. This section reveals key considerations that distinguish expert-level sourcing from basic specification.

Seamless vs. Welded: Know When It Matters

One of the most impactful—yet often misunderstood—choices is between seamless and welded stainless steel tubing:

- Welded tubing is formed by rolling stainless steel into a tube and welding the seam. It’s cost-effective and generally sufficient for structural or decorative uses.

- Seamless tubing is produced by extrusion from a solid billet, resulting in no weld seam. It offers superior uniformity, corrosion resistance, and pressure performance.

However, many buyers over-specify seamless tubing when it’s not necessary. This can double costs without adding meaningful benefit.

✅ Expert Insight: Unless the application involves high-pressure fluid systems, extreme environments, or stringent purity requirements, welded tubing with tested weld integrity is usually sufficient.

💡 Long-Tail SEO Tip: Search terms like “is seamless tubing better” or “welded vs seamless stainless steel tube” are frequently used by engineers—ideal to address in linked blog FAQs.

When choosing:

- Ask for non-destructive weld testing (e.g., eddy current, ultrasonic) for welded tubes

- Specify seamless only when demanded by pressure, purity, or regulatory codes

Understand Tolerance Classes: Prevent Costly Assembly Issues

Tolerances define how closely the tubing dimensions match the nominal specs. In assemblies involving machined or fitted parts, even slight deviations can cause major issues—misalignment, friction, or weld defects.

Tubing standards like ASTM A269 (general) and ASTM A554 (mechanical) define several tolerance classes.

🔧 Sourcing Tip: Avoid vague terms like “tight tolerance.” Instead, specify:

- OD tolerance (e.g., ±0.005″)

- Straightness limits (e.g., max deviation per meter)

- Roundness criteria (especially for precision or telescoping assemblies)

Also, request dimensional inspection reports if the tubing interfaces with other critical components.

Surface Finish Isn’t Just Cosmetic

While surface finish is often viewed as a hygiene factor, it also affects corrosion resistance, weldability, and product aesthetics—especially in exposed or consumer-facing applications.

Polished or buffed tubing resists contamination, improves cleaning, and enhances brand perception in industries like architecture, food equipment, or furniture.

📌 Example: A 180-grit finish is common in decorative use, while a mirror-polish finish (e.g., Ra ≤ 0.5 µm) might be required for biotech or laboratory systems.

When surface quality matters, define:

- Finish level (e.g., No. 4, 2B, mirror polish)

- Grit specification or Ra value

- Any post-processing (e.g., electropolishing, passivation)

Think Beyond the Tube: End Processing Adds Real Value

Raw tubing is just the start. Most real-world projects require secondary processing—and failure to plan for this early can lead to high labor costs or compatibility issues later.

Common processing needs include:

- Laser or precision cutting

- CNC bending

- End forming (swaging, flaring)

- Drilling or slotting

- Welding and sub-assembly

✅ Procurement Strategy: Work with suppliers that offer in-house processing. This ensures better dimensional control, shorter lead times, and fewer coordination errors compared to managing multiple vendors.

Also, consider packaging and labeling options—especially if the tubing ships to multiple facilities or partners.

Incorporating these expert-level practices into your procurement workflow can reduce delays, minimize rework, and deliver higher satisfaction to your clients. The result isn’t just a better tube—it’s a better sourcing experience.

IV. Stainless Steel Tubing Size Reference Table

To support better sourcing decisions, here’s a quick-reference guide to common stainless steel tubing sizes, combining typical OD and wall thickness (WT) pairings. These dimensions reflect industry standards across structural, sanitary, and high-pressure use cases.

| OD (inches) | Wall Thickness (inches) | Typical Applications |

|---|---|---|

| 0.250″ | 0.028″, 0.035″ | Instrument lines, lab systems, sensor housings |

| 0.500″ | 0.035″, 0.049″ | Beverage tubing, clean-in-place systems |

| 0.750″ | 0.049″, 0.065″ | Food equipment, furniture framing |

| 1.000″ | 0.065″, 0.083″, 0.095″ | Structural frames, sanitary processing lines |

| 1.500″ | 0.083″, 0.095″, 0.120″ | General industrial use, handrails, kiosks |

| 2.000″ | 0.095″, 0.120″, 0.154″ | High-flow piping, structural columns |

📌 Sizing Note: Some customers may provide ID-based or NPS references, which do not align directly with tubing standards. Use conversion charts and confirm OD + WT before finalizing orders.

💡 SEO Tip: Keywords like “stainless steel tubing dimensions chart” or “OD vs wall thickness for structural tubing” drive highly targeted traffic—ideal for anchoring product pages.

V. Final Takeaways: Think Like an Engineer, Source Like a Strategist

Sourcing stainless steel tubing isn’t just about reading charts—it’s about applying the right sizing logic for the intended outcome. Let’s recap the smart sourcing mindset that separates quality-focused buyers from guesswork:

✅ Start with application type — Know if you’re solving for structure, pressure, precision, or purity.

✅ Use OD-based sizing logic — Pipes use NPS (approx. ID); tubing uses exact OD and WT.

✅ Factor in tolerances and finishes — These affect performance, cleanability, and compliance.

✅ Don’t overlook secondary processing — Services like cutting, forming, or welding can improve quality and reduce risk.

✅ Know when to specify seamless vs welded — Let application demands, not assumptions, guide your call.

By using performance goals to drive tubing decisions, you reduce rework, ensure fit-for-purpose results, and increase downstream efficiency.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between NPS and OD in tubing?

A: NPS (Nominal Pipe Size) is used for piping and references approximate ID. Tubing uses true OD for precision and fit—especially in structural and mechanical use.

Q2: Can I use pipe specs for tubing applications?

A: Not recommended. Pipes and tubes are designed under different standards and tolerances. Mismatched sizing leads to performance or fitting failures.

Q3: Is seamless tubing always better than welded?

A: No. Seamless is best for high pressure or purity-critical applications. For most structural and decorative uses, welded tubing with tested welds is more economical and reliable.

Q4: What certifications should I ask for with sanitary tubing?

A: Request compliance with ASTM A270 for food-grade and ASME BPE for pharma-grade tubing. Also ask for Ra values or finish designations like SF1 or SF4.

Q5: What if I only have the ID—can I still specify tubing?

A: Yes, but confirm with a supplier. Use OD + WT estimation tools and avoid guessing. Confirm final specs in writing before production or shipment.

Q6: Can stainless tubing be ordered pre-cut or processed?

A: Absolutely. Many suppliers offer laser cutting, bending, or polishing—these services improve precision and save time downstream.

VI. About YISHANG

YISHANG is a precision metal fabrication partner with over 26 years of industry experience, specializing in custom stainless steel products including tubing, racks, enclosures, and frames. Headquartered in China and exporting to over 50 countries, we serve industries ranging from vending and electronics to clean energy and medical devices.

We are ISO 9001 and RoHS certified, and offer full-service capabilities from design support to laser cutting, TIG welding, CNC machining, polishing, assembly, and global logistics. Explore our metal fabrication capabilities to learn how we serve OEMs and engineering buyers worldwide.

📩 Looking for the best stainless steel tubing for food industry, biotech, or structural framing? Contact YISHANG today to explore how we can support your next project—from prototype to volume production.