Introduction: The Strategic Sourcing Decision on Your Desk

As a procurement professional, you face critical decisions daily. A new component is on the agenda: one supplier proposes a stamped assembly, promising speed and low unit costs. Another suggests a single-piece casting, highlighting superior strength.

It’s not just a technical choice—it directly affects your project’s total cost of ownership, supply chain efficiency, and long-term performance. In high-stakes industrial sourcing, your decision has ripple effects across inventory, timelines, and lifecycle cost.

This guide provides a decision-making framework based on real manufacturing trade-offs. It moves beyond surface-level comparisons to give you a clearer understanding of how stamping and casting align with practical procurement goals, performance demands, and risk mitigation strategies.

At a Glance: The 30-Second Sourcing Matrix

For quick, high-level comparison, this matrix summarizes the core sourcing factors. It’s tailored for professionals who need to align manufacturing choices with business objectives efficiently.

| Key Sourcing Factor | Stamped Steel | Cast Steel | The Bottom Line for Procurement |

|---|---|---|---|

| Best For | High-volume, standardized parts | Low-to-high volume, highly complex parts | Volume and complexity are the first fork in the road. |

| Geometry | 2D to 3D (from a flat sheet) | True 3D (monolithic, internal features) | If you need internal channels, casting is your only choice. |

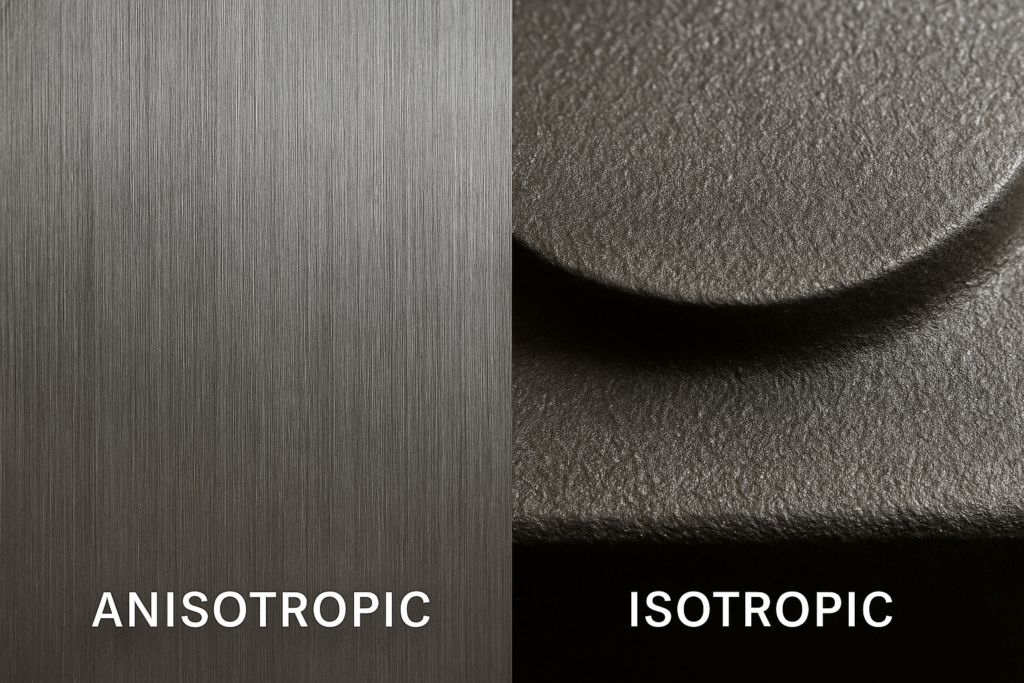

| Strength | Directional (Anisotropic) | Uniform (Isotropic) | Stamping is strong along the grain; casting is strong from any direction. |

| Cost Profile | High initial tooling, very low unit cost | Low-to-high tooling, low-to-medium unit cost | Stamping wins on massive runs; casting can win by replacing assemblies. |

| Speed | Extremely fast production cycles | Slower production cycles | Stamping is built for speed once the tooling is ready. |

The Strategic Case for Stamped Steel: Speed, Scale, and Cost Efficiency

Metal stamping is central to modern mass production. It’s designed for high speed, consistency, and scalability—key drivers of cost reduction in high-volume manufacturing.

This process uses flat sheet metal fed into a press, where tool and die sets shape it into precise parts. It’s a proven method for manufacturing brackets, enclosures, frames, and other components with well-defined 2D-to-3D profiles.

The “Litmus Test”: When Stamping Aligns with Your Sourcing Goals

Stamping is typically ideal when your sourcing priorities include:

- High Volumes with Stable Designs: Die investment pays off when amortized across tens of thousands or millions of units. Once production ramps up, cost-per-piece drops significantly.

- Sheet-Compatible Geometries: If your part can be formed from a flat pattern using punching and bending, stamping is likely the most efficient route.

- Unit Cost Pressure: Sectors like automotive and consumer electronics benefit from the speed and low unit cost stamping delivers.

- Predictable Load Conditions: Stamping leverages rolled steel’s directional grain. When loading direction is known, parts can be oriented to maximize strength without extra expense.

Risk Factors to Consider with Stamping

Despite its advantages, stamping isn’t universally applicable:

- High tooling costs require volume justification.

- Design flexibility is limited post-tooling.

- Material scrap must be planned into cost models, especially for expensive metals.

The Strategic Case for Cast Steel: Complexity, Integrity, and Flexibility

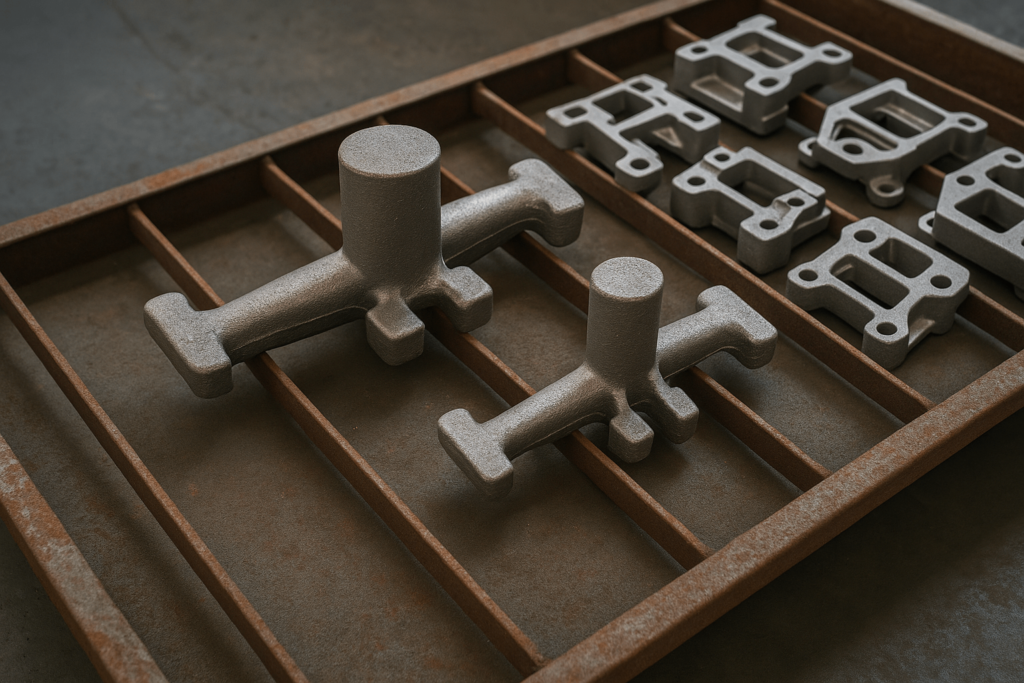

Steel casting offers unmatched design freedom and part consolidation. It excels when 3D geometry, internal passageways, or structural continuity are critical.

By pouring molten steel into molds, casting achieves configurations impossible to fabricate from sheet stock or machining alone. In sourcing terms, it may reduce assembly steps, simplify logistics, and boost long-term durability.

The “Litmus Test”: When Casting Is the Right Fit

Casting is preferred when the following apply:

- Complex Internal Features: Internal channels, gussets, and voids can be cast-in with cores—eliminating secondary machining or assembly.

- Multi-Directional Strength Needed: Cast steel cools without directional grain, giving it isotropic properties—a key advantage when loads are unpredictable or vary across axes.

- Assembly Consolidation: Moving from welded assemblies to cast parts reduces part count, weld fatigue points, and inventory complexity.

- Low-to-Mid Volume or Oversized Parts: Sand casting’s lower tooling cost and scalability make it suitable for prototyping, pilot runs, or very large industrial components.

Key Sourcing Risks Unique to Steel Casting

While casting offers design freedom, it brings its own set of risks procurement teams should account for:

- Shrinkage and Porosity: These defects require experienced gating design and rigorous quality controls.

- Surface Finish: Often rougher than stamped or machined parts, castings may need post-processing.

- Longer Lead Times: Tooling and solidification time affect responsiveness.

Expert Deep Dive: The Procurement-Centric Viewpoint

A technical understanding helps, but procurement professionals win when they grasp the hidden economic levers behind each process.

Yield & Scrap Rate: The Underestimated Cost Drivers

Stamped parts generate predictable waste from offcuts and skeletons, especially in progressive dies. Casting, however, is governed by yield ratio—usable part weight vs. total poured weight.

For example, reducing casting yield from 45% to 30% due to poor gating can increase part cost over 17%. Early supplier discussions should include gating simulations and target yield expectations.

Anisotropic vs. Isotropic: How Strength Really Works

Strength is context-specific:

- Stamped Steel: Strongest along the rolling direction—ideal for chassis or bracketry under planar stress.

- Cast Steel: Equal strength in all directions—suitable for housings, hubs, or dynamically loaded parts.

Don’t ask “which is stronger”—ask which matches the real-world loading.

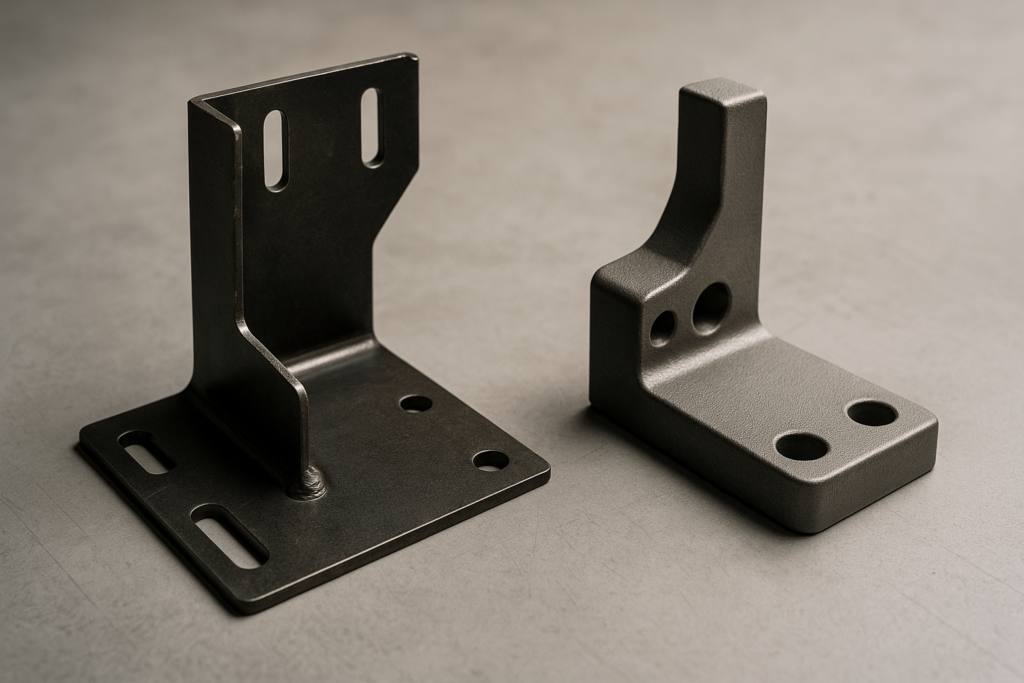

Weldment-to-Casting Conversion: The TCO Shift

One strategic sourcing tactic is converting multi-component weldments into single castings:

- A real-world case reduced 136 stamped and welded parts into just 3 castings.

- Result: 38% cost reduction, improved structural reliability, and faster assembly.

This isn’t just cost-cutting—it’s risk mitigation and quality control.

Frequently Asked Questions (FAQ)

Does Stamped Steel Rust?

Corrosion resistance depends on the alloy. Cold-rolled steel (CRS) needs protective coating. Stainless steel options (304/316) naturally resist corrosion.

Why Is Lubricant Used in Metal Stamping?

Stamping lubricants prevent tearing, reduce die wear, and ensure clean part ejection. They’re critical in deep draw or progressive die operations.

Which Process Offers Better Tolerances?

- Stamping: Tight repeatability (±0.01–0.05 mm) for high-precision operations.

- Casting: Varies by method—sand casting is looser (±0.5–2 mm); investment casting can match stamping precision.

Can Cast Steel Be Welded?

Yes. Most low-carbon cast steels are weldable. Preheating and slow cooling may be required for high-carbon grades to avoid cracking.

The Horizon: What’s Next in Steel Forming?

Anticipating future manufacturing shifts gives procurement leaders a competitive edge. Here are three methods gaining traction:

Hot Stamping (Press Hardening)

Boron steel heated to ~900°C and formed in water-cooled dies delivers ultra-high strength (~1500 MPa). It enables lighter, safer automotive parts.

Additive-Casting Hybrid Manufacturing

Combining 3D printing for complex lattice cores with casting over-molded shells enables strength-to-weight ratios ideal for aerospace and EVs.

Integrated Process Platforms

Some systems now combine die casting for bases with additive modules for internal features. This hybrid model supports localized customization.

Conclusion: Your Strategic Sourcing Framework

Stamped vs. cast steel is more than a manufacturing decision—it’s a sourcing philosophy. To choose effectively:

- Geometry: If it starts flat, consider stamping. If it’s volumetric, casting may win.

- Volume: Stamping shines at scale. Casting thrives in complexity or short runs.

- Mechanical Demand: Know your stress map—grain-aligned strength or uniform load handling?

With these lenses, you’ll move from uncertain options to confident sourcing—and translate design complexity into commercial clarity.

Have a project in motion? Now’s the time to evaluate it through the right process lens. Reach out to discuss how your component design aligns with the best steel forming method.