The Engineer’s Dilemma: Why “Through-Hardening” Isn’t Always the Answer

In mechanical engineering, a key challenge is achieving the right balance between hardness and toughness. A component’s surface often demands extreme hardness to withstand wear, while the core must retain enough toughness to absorb impact and resist fracture. This challenge is at the heart of what is surface hardening.

Through-hardening, which uniformly hardens a part, forces engineers into a compromise. High hardness increases brittleness, risking fractures under stress. This makes the surface hardening vs through hardening decision a strategic design and sourcing choice.

A Composite by Design: The Genius of Surface Hardening

Surface hardening, or case hardening, offers an elegant solution. It’s a metallurgical approach that transforms a single part into a high-performance composite. The outer “case” is selectively hardened, while the inner “core” remains ductile and shock-absorbent.

This dual-property structure—hard exterior, tough interior—is what makes surface hardening indispensable in mission-critical parts like gears, bearings, and camshafts across sectors.

More Than Performance: The Economic and Manufacturing Drivers

For wholesale buyers and procurement engineers, surface hardening delivers cost and production advantages. It allows manufacturers to use cost-effective low-carbon steels as the base material, enhancing only the surfaces exposed to wear.

Crucially, this method avoids the dimensional distortion and cracking risks seen in through-hardening thick parts. By reducing the need for corrective grinding and lowering scrap rates, it contributes to leaner, more predictable supply chains.

The Core Benefits: Key Advantages for Your Supply Chain

Understanding the advantages of surface hardening provides insight into its strategic importance.

- Increased Wear Resistance Surface hardening significantly improves resistance to abrasion and friction. A hardened outer shell—often >60 HRC—acts as a long-lasting barrier, lowering in-field failure risk.

- Enhanced Fatigue Strength Surface treatments often create residual compressive stress, which counters the tensile forces that lead to fatigue failure. This increases component lifespan in applications with cyclic loads—key for automotive and aerospace components.

- Maintained Core Toughness While the outer layer becomes extremely hard, the inner structure remains ductile. This unique combination prevents brittle failure, which is critical for dynamic-load parts.

- Dimensional Stability and Cost Reduction Techniques like nitriding and laser hardening operate at lower temperatures, minimizing distortion. This makes them ideal for precision parts and can eliminate the need for secondary machining, reducing total cost.

The Engineer’s Toolkit: A Deep Dive into Hardening Techniques

The field of metal finishing solutions is broad. Understanding the differences between surface hardening processes is key for sourcing and engineering teams seeking performance, reliability, and value.

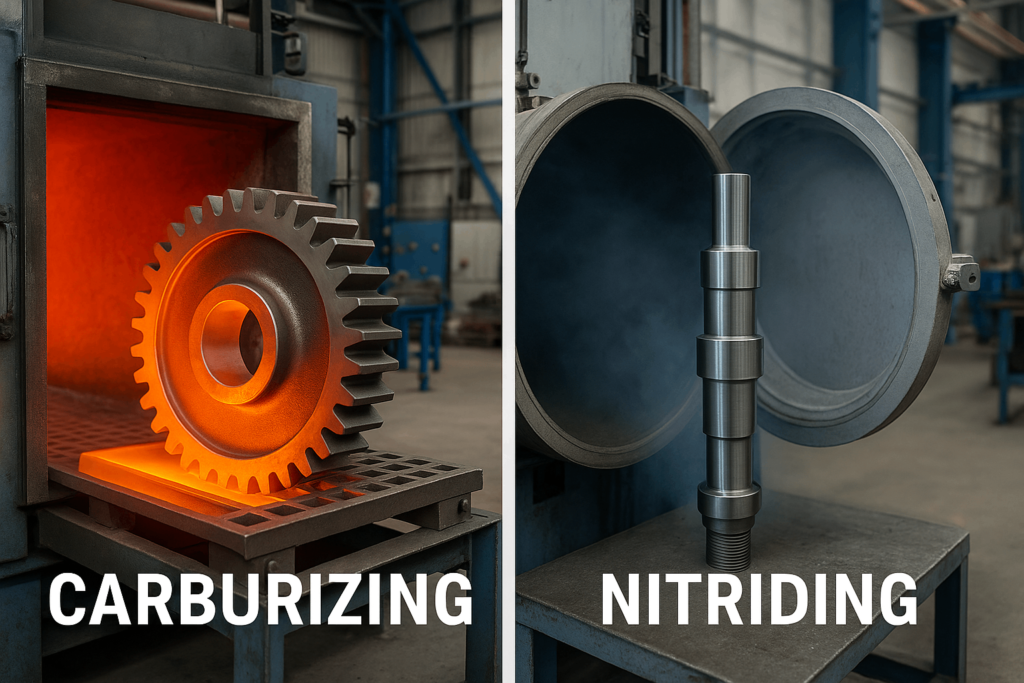

Chemical Alchemy: Carburizing vs. Nitriding

These thermochemical processes modify the steel surface’s composition to enhance hardness.

- Carburizing: Ideal for applications demanding deep, tough surface layers. Parts are heated in carbon-rich environments at 850°C–950°C. It’s widely used in gear manufacturing. However, the quenching step increases distortion risk, requiring precise post-machining.

- Nitriding: This low-temperature (500°C–550°C) process diffuses nitrogen into the metal to create nitrides—extremely hard, wear-resistant compounds. It involves no quenching, minimizing distortion. Plasma nitriding, a modern variant, offers precision and sustainability benefits.

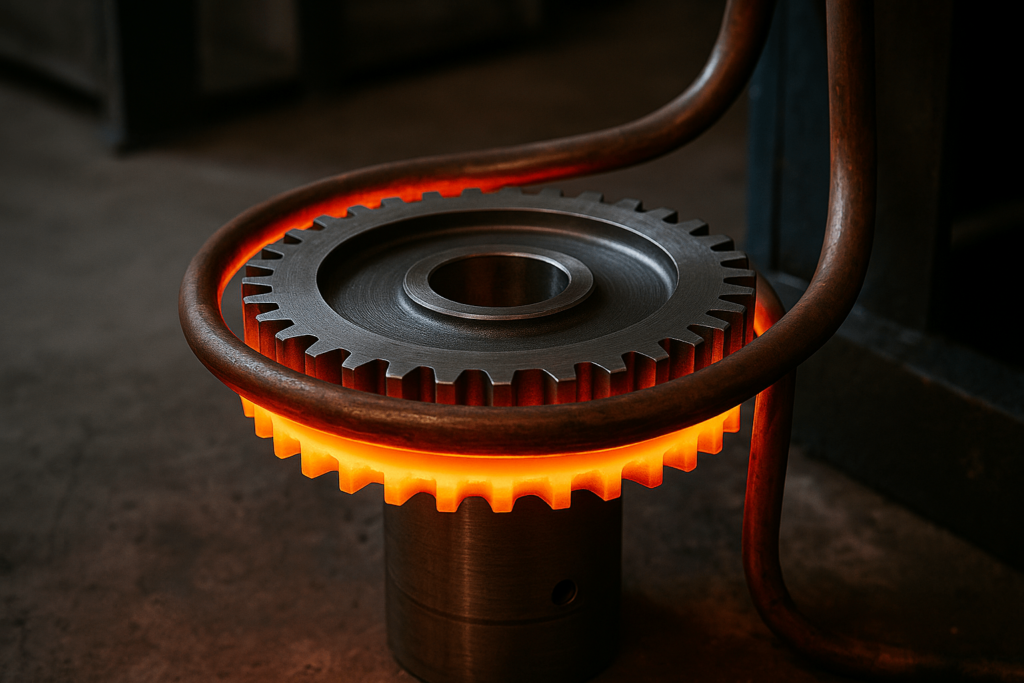

Precision Heating: Induction vs. Flame Hardening

These surface hardening methods apply rapid, localized heating and controlled cooling.

- Induction Hardening: Uses electromagnetic induction to heat specific areas precisely. Highly repeatable, this process is ideal for shafts, pins, and other standardized parts in high-volume runs.

- Flame Hardening: Uses gas flame to heat targeted areas before quenching. Cost-effective for low-volume or large, asymmetrical components. Less suited to applications requiring strict consistency.

The Ultimate Precision: Laser Hardening

The laser hardening process enables pinpoint accuracy with minimal thermal impact. A laser heats a localized area, and the surrounding material acts as a heat sink for self-quenching. The result is a hardened surface with minimal distortion—ideal for high-value, tolerance-critical components.

Mechanical Strengthening: Shot Peening vs. Roller Burnishing

These processes induce surface compressive stress through mechanical deformation.

- Shot Peening: Bombards the surface with steel or ceramic media, enhancing fatigue strength through controlled micro-deformation. It’s commonly used in aircraft and automotive components.

- Roller Burnishing: A polished roller compresses and smooths the surface, improving finish and inducing compressive stress. A 32 microinch surface finish or better is achievable, often eliminating polishing steps and lowering cost.

The Decision Matrix: How to Select the Right Surface Hardening Method

Selecting the optimal surface hardening process requires a balance of material properties, part geometry, performance needs, and cost control.

A 7-Point Checklist for Process Selection

- Material Compatibility & Cost: Does the base material support specific processes? This impacts both feasibility and cost.

- Case Depth Requirement: Heavy-duty parts may need deep cases (carburizing), while precision parts need shallow, uniform layers (nitriding).

- Distortion Tolerance: If tight tolerances are required, consider low-distortion methods like laser or nitriding.

- Part Geometry: Simple geometries suit induction hardening. Complex shapes might favor flame hardening.

- Production Volume & Scalability: For high volumes, automated processes like induction are cost-effective.

- Primary Failure Mode: If fatigue is the concern, opt for peening or nitriding. For abrasive wear, carburizing or laser hardening may be better.

- Overall Cost & Lead Time: Consider all costs—including post-processing and time—to choose the most efficient option.

The Ultimate Comparison Matrix

| Process | Material Applicability | Typical Case Depth | Distortion Risk | Relative Cost/Efficiency | Key Advantage for Procurement |

|---|---|---|---|---|---|

| Carburizing | Low-Carbon & Alloy Steels | Deep (0.5 – 6.5 mm) | High | Medium Cost / Long Cycle | Deep, tough case for heavy loads; cost-effective at scale |

| Nitriding | Alloy Steels (Cr, Mo, Al) | Shallow (0.1 – 0.5 mm) | Very Low | Medium Cost / Very Long Cycle | Minimal distortion reduces post-processing; high precision |

| Induction Hardening | Medium/High-Carbon Steels | Medium (0.5 – 5.0 mm) | Low | High Initial Cost / Very Fast Cycle | Fast, repeatable, ideal for high-volume automation |

| Flame Hardening | Medium/High-Carbon Steels | Deep (1.5 – 6.0 mm) | Medium-High | Low Initial Cost / Fast Cycle | Flexible for large/irregular parts and small batches |

| Laser Hardening | Medium/High-Carbon Steels | Shallow (0.1 – 2.0 mm) | Very Low | Very High Cost / Fast Cycle | Ultimate precision, minimal heat input, ideal for high-value parts |

| Shot Peening | Most Metals | N/A (Stress Layer ~1mm) | Low | Low Cost / Fast Cycle | Excellent fatigue life improvement for critical components |

| Roller Burnishing | Most Ductile Metals | N/A (Stress Layer <1mm) | Very Low | Medium Cost / Fast Cycle | Improves fatigue & surface finish simultaneously |

Surface Hardening in Action: Demonstrating Experience in Demanding Industries

Application examples help validate process capability for discerning buyers.

- Automotive: Transmission gears are typically carburized to provide the case strength needed to endure extreme torque without internal failure.

- Aerospace & Defense: Aircraft landing gear components are shot peened to increase fatigue resistance, critical for safety during repeated high-load landings.

- Tool & Die: Injection molds and stamping dies require extreme dimensional stability. Plasma nitriding delivers hardness with negligible distortion, preserving tool precision.

Ensuring Specification Compliance: Our Approach to Quality Control

Each part undergoes rigorous surface hardening quality control before delivery. We combine destructive and non-destructive testing to verify compliance.

Destructive Analysis for Process Validation

- Metallographic Analysis: Examines grain structure and case depth via cross-section.

- Microhardness Profiling: Maps hardness from surface inward to confirm gradient and depth compliance.

100% Non-Destructive Testing (NDT)

- Hardness Verification (HRC): Confirms surface hardness quickly.

- Magnetic Particle Inspection (MPI): Detects surface/subsurface flaws in ferromagnetic parts.

- Liquid Penetrant Inspection (LPI): Highlights cracks or porosity in non-ferrous parts.

The Future of Surface Engineering: Innovations for Your Supply Chain

As new technologies emerge, we continuously evolve our metal finishing services.

1+1 > 2: Combining Plasma Nitriding + PVD Coating

Duplex treatment strategies are gaining ground. For example, plasma nitriding followed by PVD creates a robust surface that resists cracking and delamination, ideal for high-load applications.

Meeting the Industry’s Next Challenges

- Sustainability: Low-emission technologies like vacuum carburizing gain favor.

- Smart Manufacturing: AI-based simulations cut lead times and reduce process variability.

- Additive Manufacturing: As 3D-printed metals grow, we adapt our processes to serve new microstructures.

Conclusion: Surface Design as a Competitive Advantage

Surface hardening bridges the gap between material cost and high performance. It transforms commodity metals into engineered components capable of excelling in extreme conditions.

For OEM buyers and engineers, the takeaway is clear: Think beyond base metal. Prioritize surface design early in the sourcing or R&D phase to achieve performance, durability, and cost-efficiency.

Our team is here to support with tailored surface hardening solutions that meet your exact specifications. Connect with YISHANG to discuss how we can help you deliver reliable, hardened components at scale.

Frequently Asked Questions (FAQ)

What is the best surface hardening method for CNC parts?

For CNC-machined components requiring minimal distortion and high surface hardness, plasma nitriding or laser hardening is often ideal. These methods provide precision hardening without compromising dimensional accuracy.

How deep is case hardening typically?

The depth depends on the process: carburizing can reach 0.5–6.5 mm, while nitriding typically produces a case depth of 0.1–0.5 mm. Induction and flame hardening offer customizable depth depending on frequency and duration.

Is surface hardening suitable for stainless steel (e.g., 304 or 316)?

Yes, but with limitations. Traditional hardening methods are not effective on austenitic stainless steels. However, plasma nitriding or low-temperature nitriding can harden 304/316 without affecting corrosion resistance.

Can surface hardening be applied to aluminum or non-ferrous alloys?

Most traditional surface hardening methods are not effective on aluminum. Instead, anodizing or thermal spray coatings may be used depending on application. For copper/brass, mechanical burnishing may help improve surface resistance.

Does YISHANG offer custom surface hardening services for OEM and bulk orders?

Absolutely. We specialize in OEM surface hardening for auto parts, low-distortion heat treatment for aerospace shafts, and precision case hardening for mold and tooling components. Our services support high-volume B2B sourcing across over 50 countries.