In the domain of electrical engineering and industrial automation, the integrity of a connection is paramount. It dictates the safety, reliability, and operational lifespan of the entire system.

While significant focus is placed on active components, the enclosures housing the wiring are equally critical. Therefore, the decision between a terminal box vs junction box is not a trivial choice; it is a strategic engineering decision with profound implications on installation efficiency, long-term maintainability, and the Total Cost of Ownership (TCO).

This guide is written for professionals who specify and procure components for large-scale projects. We will move beyond superficial definitions to provide a definitive technical comparison, helping you make the optimal choice for your applications, every time. Based on decades of experience manufacturing custom electrical enclosures for OEMs, this analysis incorporates real-world use cases and design standards.

Part 1: The Executive Summary — Terminal Box or Junction Box?

For professionals needing a high-level answer for a bill of materials, the decision hinges on a single factor: are you managing simple power distribution or a complex control system?

This quick decision matrix provides an at-a-glance terminal box vs junction box comparison tailored for project evaluation.

| Attribute | Junction Box | Terminal Box |

|---|---|---|

| Primary Engineering Function | Simple power distribution and circuit branching | Structured wiring interface for control systems |

| System Complexity | Low (e.g., 1 input, 3 outputs) | High (e.g., dozens or hundreds of I/O points) |

| Initial Procurement Cost | Very Low | High |

| Long-Term Maintainability & TCO | High maintenance cost in complex setups | Low TCO in complex systems due to reliability |

| Core Technology | Wire connectors (e.g., wire nuts, lever nuts) | Modular DIN rail system with terminal blocks |

When Should You Use a Junction Box?

A junction box is the correct specification when the primary goal is to safely enclose a limited number of wire splices for simple electrical connections.

Its application is ideal for residential wiring, commercial power distribution for lighting, and scenarios where a single circuit is branched to multiple static loads. As a result, its function is fundamental: containment and protection at a low unit cost.

When Is a Terminal Box the Better Choice?

A terminal box is the preferred specification for any complex electrical system where organization, serviceability, and long-term connection integrity are required.

It is the industry standard for industrial terminal enclosures and automation wiring, representing an investment in reliability and operational uptime.

Part 2: What’s Inside? Comparing Junction and Terminal Box Design

To make an informed specification, one must understand the fundamental design philosophies that differentiate these enclosures.

What Are Junction Boxes Used For — And Why Are They Still Relevant?

Their primary purpose is to house and protect electrical wire connections, ensuring operational electrical safety and preventing short circuits. It is the ubiquitous workhorse of residential and light commercial wiring.

It’s important to distinguish between a standard junction box and a pull box. While both house connections, a junction box vs pull box comparison shows a pull box is typically larger and used in long conduit runs to make pulling wires easier, rather than for complex splicing.

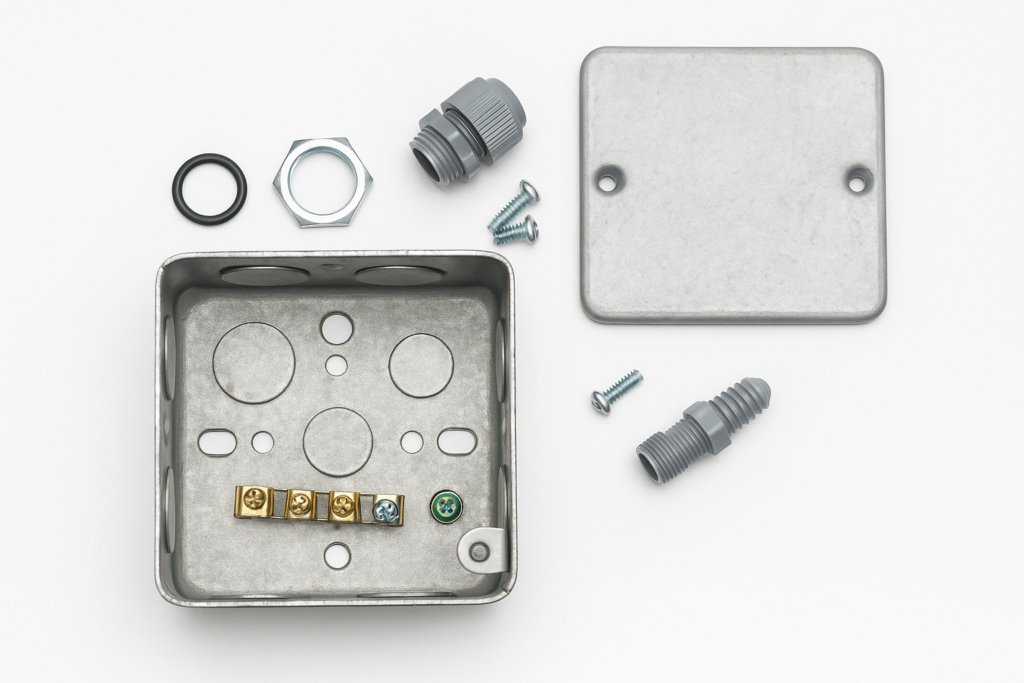

Inside a Metal Junction Box: Key Components That Matter

A standard junction box is a minimalist enclosure, typically fabricated from plastic or metal materials such as galvanized steel or stainless steel. Its key junction box components include the outer shell, knockouts for cable entry, a cover plate, and a threaded grounding screw in metallic boxes.

How Do Splice Methods Impact Junction Box Reliability?

The long-term reliability of any junction box installation depends entirely on the quality of the connections within. For a procurement specialist, understanding the trade-offs is key to evaluating long-term performance versus initial cost.

- Wire Nuts (Twist-on Connectors)

- Lever Nuts (Wago-style)

- Crimp Connectors

Each of these has its own strengths, and choosing the right one enhances overall reliability.

Why Terminal Boxes Excel in Industrial Applications

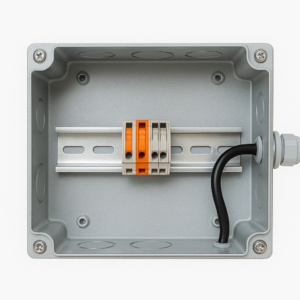

A terminal box is not merely a container; instead, it is a sophisticated, modular interface designed for the organized wiring and management of complex systems.

Its core function is to serve as a clean, serviceable transition point between field devices and the central control panel interface, directly addressing the industrial demands for organization, reliability, and ease of maintenance.

What Is a DIN Rail System — and Why Should You Care?

The DIN rail system inside an industrial terminal box allows electrical components to be mounted securely and efficiently. Moreover, this standardized mounting solution dramatically reduces panel wiring time, simplifies layout, and enables efficient space usage.

Terminal Block Types and Connection Technologies You Should Know

- Screw Terminals

- Spring-Clamp Terminals

- Push-in Terminals

Each technology affects installation time, vibration resistance, and maintenance intervals—key factors for buyers of metal terminal boxes and control cabinets.

Part 3: Which Box Works Best in Real-World Use Cases?

Case 1: Agricultural Irrigation Systems — Why Terminal Boxes Matter

A terminal box provides the structured interface between sensors, valves, and PLCs across long irrigation systems. These custom electrical enclosures simplify cable routing and reduce downtime.

Case 2: Outdoor Lighting Projects — The Role of Junction Boxes

In pole lighting projects, outdoor waterproof junction boxes offer basic protection and quick installation with minimal wiring complexity. Therefore, they remain a cost-effective solution in low-complexity environments.

Part 4: Environmental & Standards Guide — What Should You Look For?

IP Ratings and Outdoor Suitability

For external or dusty environments, selecting the right IP-rated junction box or terminal enclosure is critical. Typically, IP66 and above are preferred for heavy-duty applications.

What Metal Is Best for Your Enclosure?

Material choice affects lifespan, corrosion resistance, and cost.

- Stainless Steel: Best for marine or hygiene-critical industries

- Galvanized Steel: Economical and rugged

- Aluminum: Lightweight and moderately corrosion resistant

Certifications and International Compliance

Always look for UL, CE, RoHS, and ISO 9001 marks when choosing an OEM junction box supplier, since these standards ensure product safety and quality.

Part 5: How to Avoid Common Selection Mistakes

Avoid these errors when choosing between terminal and junction boxes:

- Using a junction box where a terminal box is needed

- Overlooking service space and cable clearance

- Ignoring IP ratings for harsh environments

- Not grounding your metal enclosures properly

Being mindful of these points helps reduce failure rates and enhances long-term system performance.

Part 6: What’s Next — Are Smart Enclosures the Future?

Terminal boxes are evolving with the integration of:

- Industrial Ethernet modules

- Smart I/O systems

- Remote signal conditioning

Clearly, your custom metal enclosure manufacturer should provide flexibility for emerging control technologies.

Conclusion: Ready to Specify the Right Box?

While the junction box and terminal box may seem interchangeable, their applications, functionality, and system value differ significantly. As a result, making the correct selection is a strategic investment in reliability and safety.

Partner with a manufacturer who understands your project complexity. YISHANG delivers metal terminal and junction boxes engineered for durability, tailored to meet international requirements. Contact our team to discuss your OEM enclosure requirements today.