In professional metal fabrication, selecting the right welding process is a critical strategic decision. It’s a choice that directly impacts a product’s final appearance, its structural integrity, production speed, and the total cost of fabrication.

For engineers, designers, and procurement managers making significant supply chain decisions, understanding the core difference between TIG and MIG welding is essential for specifying a product that meets every performance and budget requirement.

This guide provides a clear, business-focused analysis of TIG vs. MIG—exploring what they are, when to use each, and how to align the right method with your production goals.

1.0 The Executive Summary: What You Need to Know Now

For professionals who need a direct answer, the distinction can be summarized by the primary objective of the weld. Is it for absolute precision and aesthetic perfection, or for production speed and manufacturing efficiency?

1.1 Key Takeaways for Your Project

TIG is for Precision & Aesthetics. Gas Tungsten Arc Welding (GTAW), or TIG, is the definitive choice when the final appearance of the weld is a critical design feature. It is the go-to process for thin-gauge metals and non-ferrous materials like aluminum.

Based on 26+ years of production experience, TIG is the required method for “showcase” pieces—where the weld must reflect quality and craftsmanship.

MIG is for Speed & Efficiency. Gas Metal Arc Welding (GMAW), or MIG, is the workhorse of modern manufacturing. It’s selected for projects where production speed and cost-effectiveness are the primary drivers.

MIG is perfectly suited for joining thicker materials, fabricating robust structural components, and executing long, continuous welds in high-volume production runs.

1.2 Quick Comparison Table: The Process vs. The Outcome

To better visualize this TIG vs. MIG welding comparison from a procurement perspective, consider how the process choice directly impacts the final product outcome:

| Decision Factor | TIG (The Surgeon’s Scalpel) | MIG (The Production Engine) |

|---|---|---|

| Best For | Thin-gauge metals, aluminum, stainless steel | Thicker steel, production runs, structural components |

| Final Appearance | Excellent, clean, precise “stack of dimes” bead | Functional, strong bead; post-weld grinding may be required |

| Strength | Superior purity and integrity for critical joints | Strong and reliable for industrial-grade applications |

| Speed & Cost | Slower process, higher labor cost | Faster process, cost-effective for volume |

2.0 The One Fundamental Difference That Changes Everything

The entire difference between MIG and TIG debate, with all its nuances, originates from a single, fundamental distinction in their mechanics: the nature of the electrode.

TIG welding utilizes a non-consumable tungsten electrode, chosen for its high melting point (3,422°C), allowing it to sustain arc heat without melting. Filler metal is added manually, offering extreme control.

MIG welding uses a consumable wire electrode, which feeds automatically through the welding gun—serving both as arc conductor and filler metal source. This integration supports speed and scalability.

3.0 How the Welding Process Impacts Your Final Product

For B2B clients, the technical choice directly affects appearance, strength, metal compatibility, and production cost.

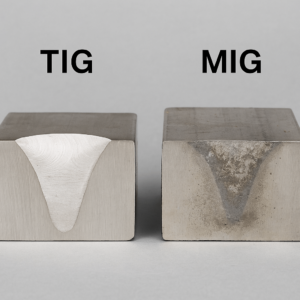

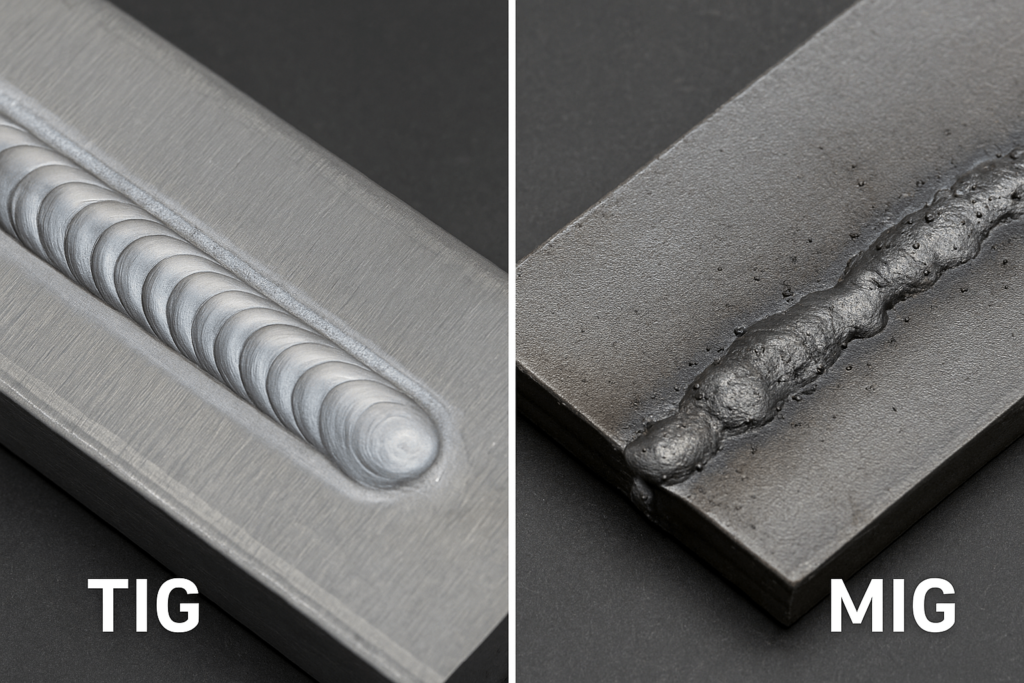

3.1 Aesthetics & Final Finish: The Look of the Weld

For industries like architecture, medical devices, or premium consumer hardware, visual weld quality matters as much as strength.

TIG allows unmatched control, producing clean, uniform welds. Its hallmark ripple finish reflects craftsmanship and often requires no grinding or cleanup.

MIG, while functional, may result in more raised beads and surface spatter. Where finish isn’t exposed—or is powder-coated—MIG is a practical solution.

3.2 Strength & Structural Integrity: Beyond the Surface

TIG offers higher metallurgical purity and tighter control over the Heat-Affected Zone (HAZ), reducing material distortion and enhancing fatigue life—ideal for aerospace or critical load-bearing parts.

MIG provides excellent strength and fusion, and is globally adopted in automotive frames and industrial equipment. Proper settings and inspection mitigate the risk of cold lap or incomplete fusion.

3.3 Material Compatibility & Limitations

TIG handles thin-gauge and non-ferrous metals best—especially aluminum and magnesium, where AC TIG removes oxide layers through its cleaning cycle.

MIG works best on ferrous metals like mild or carbon steel. While MIG aluminum welding is possible with spool guns and argon gas, it lacks TIG’s oxide-cleaning efficiency.

3.4 Production Speed, Scale, and Total Cost of Fabrication

TIG has a lower deposition rate (0.5–2 lbs/hr), ideal for small-batch, premium work.

MIG reaches 2–12 lbs/hr or more, making it optimal for high-throughput production. Its faster speed minimizes labor cost and maximizes ROI in batch orders.

4.0 Industry Applications: Where Each Process Excels

Understanding practical use cases helps clarify the strategic benefits.

4.1 TIG Welding Applications

- Aerospace: Engine parts, tubing, precision joints

- Medical: Cleanroom tools, surgical-grade welds

- Architectural: High-finish handrails, display elements

- Food Equipment: Sanitary stainless tanks and piping

4.2 MIG Welding Applications

- Automotive: Chassis, exhaust, brackets

- Industrial Machinery: Enclosures, structural arms

- Construction: Beams, platforms, reinforcements

- Retail Fixtures: Metal cabinets, display racks, vending frames

5.0 Debunking Common Misconceptions

5.1 “MIG Is Low Quality”

False. When properly applied, MIG welds are strong and industrial-grade. Aesthetic difference does not mean functional inferiority.

5.2 “TIG Is Always Better”

Not necessarily. TIG is ideal when finish or tight tolerances matter. For high volume, MIG is often the smarter option.

6.0 The Skill Factor: Operator Expertise Required

TIG requires fine motor control, pedal modulation, and dual-hand coordination—making it labor-intensive and harder to scale.

MIG allows easier adoption for less experienced operators. It’s the preferred method for large teams with mixed experience levels.

Both methods benefit from qualified procedures and consistent quality checks.

7.0 Evolution of Welding Technology: Modern Adaptations

7.1 Pulsed MIG & TIG

Pulse modes in both systems improve control and reduce heat distortion, expanding their use on thinner or more delicate metals.

7.2 Robotic Integration

MIG leads in automated production lines, especially for batch manufacturing. TIG robotics, while complex, is emerging in aerospace and high-precision fields.

8.0 Decision Framework: How to Choose the Right Process

- Metal Type & Thickness: Thin/non-ferrous → TIG; Thick/steel → MIG

- Appearance Requirement: Exposed welds → TIG

- Volume & Lead Time: High output → MIG

- Operator Skill Level: Limited expertise → MIG

- Post-Finishing Tolerance: Minimal finishing → TIG

Our engineering team routinely guides buyers through these exact variables to ensure a match between performance, cost, and manufacturability.

9.0 Final Thoughts: Precision or Productivity?

TIG is unmatched for detail, non-ferrous metals, and visible joints.

MIG delivers speed, consistency, and volume at scale.

Choosing the right welding method isn’t about “better”—it’s about what aligns with your operational priorities.

📩 Still unsure which process fits your application best?

Get a free welding method evaluation from our engineering team—no commitment, just clarity. [Request Evaluation →]