Key takeaways for overseas volume buyers

- Titanium CNC machining success depends on system stability, not machine capability alone.

- Heat accumulation and elastic deformation are the primary drivers of batch-to-batch drift.

- Prototype success does not guarantee production readiness.

- Predictable tooling, controlled fixturing, and correct inspection timing reduce sourcing risk.

- RFQs that clarify volume, critical dimensions, and inspection intent lead to more reliable quotes.

Titanium CNC machining is often described as “difficult” or “expensive.” For overseas wholesale buyers, those labels are not the real decision criteria. What matters is whether a supplier can deliver repeatable quality, predictable lead times, and controlled risk when an order moves from first samples to ongoing batch production.

If you source CNC titanium parts for equipment, industrial assemblies, or product platforms, you already know the stakes: a single unstable dimension can disrupt assembly, trigger rework, or delay shipments. The challenge is not whether titanium can be cut—it is whether the process remains stable as heat accumulates, tools wear, and fixtures cycle through repeated clamping.

This article is written for professional buyers who evaluate titanium machining services based on production outcomes. It focuses on production behavior, common failure patterns, and supplier evaluation signals that matter in real sourcing decisions—without relying on marketing language.

Titanium CNC Machining Is a Production System, Not a Single Capability

From a procurement standpoint, titanium CNC machining should be evaluated as a manufacturing system rather than a standalone operation. Most CNC machines can cut titanium alloys, but consistent production requires the entire system—tooling, fixturing, thermal control, inspection timing, and process discipline—to behave predictably over time.

What makes titanium different is how small variations accumulate. A slight change in cutting temperature, a gradual shift in tool edge condition, or a minor difference in clamping force may have no obvious impact on the first few parts. Over dozens or hundreds of cycles, those same differences can compound into measurable drift: hole position changes, flatness shifts, and surface integrity varies even when the CNC program stays identical.

For volume buyers, this explains a common sourcing trap: a prototype can look perfect while the process is still fragile. In early runs, tools are fresh, machines are cool, and operators pay unusually close attention. The outcome looks convincing, but it does not prove production readiness.

To evaluate titanium machining capability realistically, buyers should focus on how a supplier controls the system across time. That includes how they manage heat accumulation, how they define tool-life strategy, how they design workholding for thin sections, and how they validate results after stress is released. When those controls are in place, titanium machining becomes manageable and predictable. When they are not, cost and lead time become volatile.

How Titanium Behaves Differently During CNC Machining

Titanium’s machining behavior is driven by physical properties that have direct implications for stability. Two characteristics matter most in day-to-day production: thermal behavior and elastic response. Understanding these helps buyers interpret why titanium projects can “look fine” in early inspection yet fail in assembly or later batches.

Heat Concentration and Thermal Load

Titanium has low thermal conductivity, typically around 6–7 W/m·K. For context, carbon steel is roughly ~50 W/m·K, and aluminum is 200+ W/m·K. In titanium CNC machining, this means the heat generated at the cutting zone is not carried away efficiently by chips. Instead, heat stays concentrated near the tool–workpiece interface.

That localized heat changes the economics and stability of the process. Tool edges see higher temperature, which accelerates wear and increases friction. As friction increases, even more heat is generated—creating a feedback loop. This is why titanium milling and turning can drift over long runs even with consistent parameters.

The practical buyer takeaway is straightforward: if a supplier can only show short-run sample success, you still do not know how their process behaves after the machine reaches thermal equilibrium. Production-grade capability requires thermal management that remains stable across cycle time, fixture cycles, and tool changes.

Elastic Deformation and Stress Storage

Titanium also has a lower elastic modulus than many steels, which means it can deform elastically under cutting and clamping forces. During machining, fixtures and clamps restrain the part, and the part appears stable. But elastic energy can remain stored within the component.

Once the part is unclamped, that stored energy is released. Distortion, twist, or dimensional shift may happen after machining rather than during it. This is especially common in thin-wall titanium machining, open frames, asymmetrical brackets, and deep pocket geometries.

For buyers, elastic behavior explains why “in-fixture inspection” can be misleading. A part may measure within tolerance while restrained, then move outside tolerance after release. Suppliers who understand titanium’s elastic response adjust sequencing, workholding, and inspection timing to make final measurements reflect the true free-state geometry.

Why Titanium Parts Pass Inspection but Fail After Unclamping

Many titanium sourcing issues show up at a frustrating moment: parts pass inspection, ship on time, and then fail during assembly. When this happens, it is tempting to treat the problem as random. In reality, post-unclamping distortion is a predictable effect of how stress is introduced and released during machining.

During cutting, titanium parts experience a combination of mechanical and thermal loading. Cutting forces create stress gradients, and localized heat creates uneven expansion. Clamping forces then restrain the part, which can mask elastic deformation and hold the part in an “artificially correct” shape.

Once the part is unclamped, the constraint is removed. Stress redistributes and the part moves toward a free-state equilibrium. Thin walls, long unsupported features, and parts with uneven wall thickness are particularly sensitive. This is why certain designs remain stable in steel but distort in titanium under the same fixture style.

For overseas buyers, this point matters because it changes how you evaluate supplier competence. A supplier that measures only in-fixture, or measures immediately after machining, may report acceptable results while still shipping unstable parts. In contrast, a production-ready supplier will define inspection timing based on stress release and thermal stabilization.

A practical approach many buyers request is a staged inspection plan:

| Inspection stage | Purpose | Typical timing (example) |

|---|---|---|

| In-process checks | Detect tool breakage or gross offsets | During run, at defined intervals |

| Post-unclamp measurement | Validate free-state geometry | After unclamping and short stabilization |

| Final inspection / FAI | Confirm full drawing compliance | After full process sequence |

The exact timing depends on geometry and process, but the principle is stable: final quality should be verified after constraints are removed. This single change often prevents downstream surprises.

Heat Accumulation as the Primary Driver of Instability

Among the variables that affect titanium machining services, heat accumulation is the most influential—and the hardest to detect from short runs. Because titanium does not dissipate heat efficiently, thermal load builds gradually. A process can appear stable early in a shift and then drift as equilibrium changes.

As heat accumulates, tool wear accelerates and cutting forces increase. This changes effective tool geometry and raises deflection risk on thin features. Surface integrity may also degrade, introducing residual stress that later contributes to distortion or fatigue issues. These effects typically emerge over time rather than immediately.

For buyers, this explains why sample approval alone is not enough. Production stability depends on how the supplier manages thermal behavior across full batches. Suppliers with experience in cnc titanium production can usually explain how they control chip evacuation, cutting engagement, and tool change timing as the machine warms up.

Production example (simplified):

A thin-wall titanium bracket may hold tolerance on the first 10–15 pieces. As heat accumulates, a critical hole position can drift by several microns due to combined tool wear and elastic deflection. A stable process anticipates this behavior and controls it through staged machining, defined tool life, and post-unclamp inspection—rather than reacting after parts fail.

When buyers compare quotes, heat management often explains price differences. Lower-cost offers may assume aggressive cutting and minimal monitoring, accepting higher scrap risk. A disciplined process may cost more per part but delivers lower total cost by avoiding rework, delays, and functional failures.

Suppliers who manage heat effectively often track:

- Tool wear trends across a run

- Dimensional drift on critical features

- Scrap or rework rate by batch

- Process capability (e.g., Cpk) on key dimensions

These indicators align directly with what overseas buyers value: predictable supply and consistent quality.

Tooling Strategy Focused on Predictability and Risk Control

In volume procurement, tooling strategy should prioritize predictable output rather than peak speed. In titanium, aggressive optimization can reduce cycle time on the first parts but often increases variability as heat and wear accumulate. For buyers, this shows up as unstable dimensions, inconsistent surface condition, or sudden quality shifts mid-batch.

A production-grade tooling strategy is designed around repeatability. Tool geometry is selected to reduce friction and keep chip formation stable. Coatings can help maintain edge performance at elevated temperatures, but coatings do not “solve” titanium if the cutting mechanics are unstable.

What matters most in supplier discussions is not whether they use a famous tool brand, but whether they can explain how they control tool behavior. Buyers can often learn more from the supplier’s wear strategy than from their speed-and-feed claims.

Here is a practical example of how a predictable strategy is different from a fast strategy:

| Objective | Fast strategy (riskier) | Predictable strategy (production-ready) |

|---|---|---|

| Tool life approach | Push limits, change after failure signs | Planned change intervals based on trend |

| Thermal behavior | Peaks and swings | Controlled, stable heat generation |

| Quality result | Good early parts, drift later | Consistent dimensions across batch |

| Procurement outcome | Higher risk of delays and rework | More stable lead time and yield |

For buyers sourcing cnc titanium components, predictable tool wear is often more valuable than maximum tool life. Consistent wear enables scheduled tool changes, stable tolerances, and fewer unexpected stops. Unpredictable wear introduces delivery risk and increases total cost even if the quoted unit price is lower.

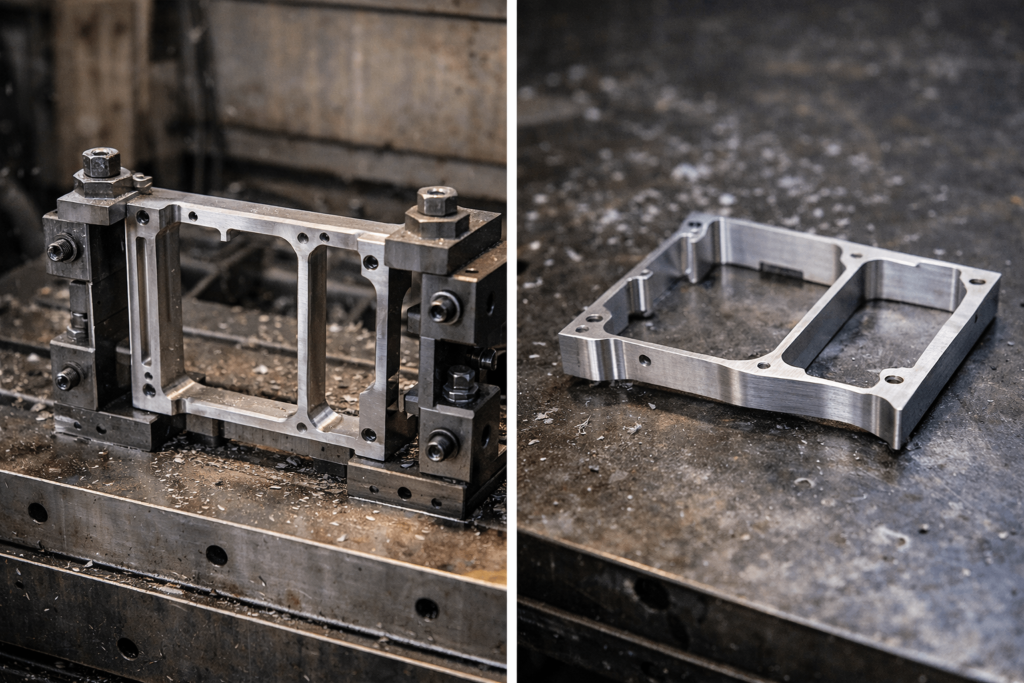

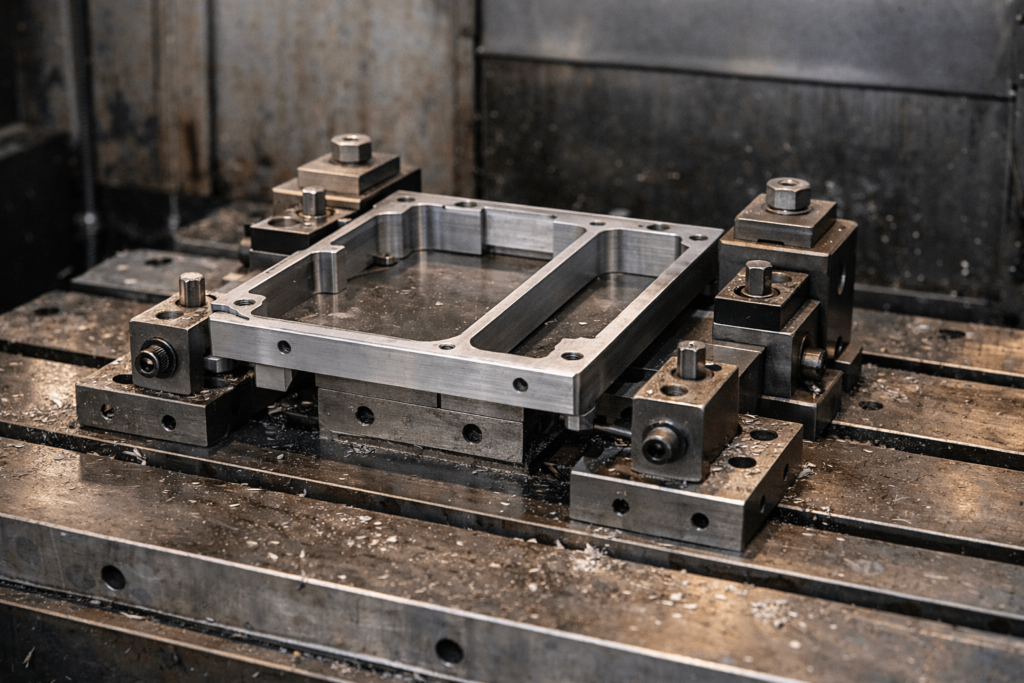

Fixturing as a Control Mechanism, Not a Setup Detail

Fixturing is one of the most underestimated drivers of success in titanium CNC machining, especially for thin sections, frames, and parts with large pockets. A fixture is not just a setup item—it is part of the machining system that determines how stress is introduced and how the part behaves after release.

Traditional workholding logic for steel often relies on high clamping force to maximize rigidity. In titanium, excessive clamping force can introduce hidden distortion. The part may look stable during machining and measurement, then move after unclamping as elastic energy is released.

Production-ready fixturing distributes support rather than forcing restraint. Multi-point support and controlled clamping force reduce localized stress and limit post-release movement. The goal is not to eliminate all deflection—every setup deflects—but to keep deflection predictable and repeatable.

For overseas buyers, fixture strategy is a strong supplier capability signal. A supplier with real titanium experience will typically discuss how they:

- Support thin walls without over-clamping

- Control datum strategy across multiple operations

- Minimize stress concentration near critical features

- Validate free-state geometry after unclamping

These are not “nice-to-have” details. They are directly tied to yield, assembly success, and repeatability.

Titanium Grades and Their Role in Production Stability

Titanium grades matter, but not in the way many generic articles imply. Grade selection influences cutting forces and heat behavior, yet it cannot compensate for an unstable process. In titanium CNC machining, grade choice becomes most meaningful after the process is stable and repeatable.

Ti‑6Al‑4V (Grade 5) is widely used for its balance of strength and corrosion resistance. Its microstructure maintains strength at elevated temperatures, which increases cutting force and heat retention. That is one reason machining Ti‑6Al‑4V can be less forgiving than machining commercially pure grades.

For procurement teams, grade discussion should include material form and specification control, not only the grade number. Buyers often use standards such as ASTM B348 (titanium and titanium alloy bars and billets) for material traceability in industrial supply chains, and specific medical or aerospace standards where applicable. While a material certificate supports traceability, it does not guarantee machining repeatability on its own.

A practical sourcing takeaway is that “same grade” does not always behave the same. Material condition, batch variability, and heat treatment state can influence machining response. A supplier who can manage those variables through process control and incoming material handling typically delivers more stable results.

From Prototype to Batch: Where Titanium CNC Machining Often Breaks Down

Prototype success is a weak predictor of production success in titanium machining. Prototypes benefit from fresh tools, low cumulative heat, and extra attention. Batch production exposes the process to sustained thermal load, progressive wear, and repeated fixture cycling.

As volume increases, small variations compound. Heat accumulation shifts cutting conditions. Tool wear changes effective geometry. Fixture stress cycles repeat, sometimes introducing slight changes in part restraint. A process that is marginally stable in prototyping can drift outside tolerance in production.

For wholesale buyers, this is the most important evaluation lesson: sample photos and first-article dimensions are not enough. The supplier must demonstrate production readiness—how they maintain stability after dozens or hundreds of parts.

If you want to evaluate readiness without adding heavy bureaucracy, one useful approach is to align on a small set of critical dimensions and request trend data across a run. Even a simple trend chart across a batch provides more insight than a perfect single report.

This is also where buyer and supplier expectations should match. If tolerances are extremely tight, thin-wall geometry is aggressive, or surface integrity is critical, the process window becomes narrower. Stable suppliers typically handle that by investing in controlled sequencing, defined tool change intervals, and measurement timing that reflects free-state geometry.

How Wholesale Buyers Should Evaluate Titanium Machining Capability

Capability vs. Control: The Core Evaluation Lens

For overseas procurement teams, evaluating titanium machining capability is less about marketing claims and more about the supplier’s process discipline. Equipment lists, certificates, and surface-finish photos can be useful, but they do not reveal long-run stability. Buyers with experience sourcing titanium quickly learn that the key distinction is not whether a supplier can make the part once, but whether they can keep making it the same way.

A practical evaluation framework separates capability from control. Capability answers the question, “Can you machine this titanium part at all?” Control answers, “Can you repeat the same outcome across batches, operators, and shipment windows?” In titanium CNC machining, control is what protects lead time, assembly yield, and total landed cost.

What Process Explanations Reveal About Supplier Maturity

One of the strongest indicators of control is how a supplier explains their process. Experienced titanium machining suppliers tend to describe heat behavior, tooling wear, workholding, and inspection timing as a connected system. They can explain what changes between prototype runs and batch production, and why those changes matter.

When explanations remain superficial—focused mainly on machine specifications, generic experience claims, or isolated sample success—buyers should assume additional risk exists beneath the surface. Clear, process-based explanations usually signal that the supplier has already managed similar challenges in production.

Evidence That Matters More Than One-Time Reports

Another effective evaluation method is to ask for trend evidence, not just a single inspection report. A single FAI or dimensional report can look perfect while the process itself remains fragile. Trend evidence, such as how a critical dimension behaves across a production run, reveals whether the process is stable or drifting.

Buyers do not always need full statistical process control to gain insight. Even a simple comparison of early-run versus later-run measurements on a key feature can highlight whether heat accumulation, tool wear, or fixturing effects are being controlled.

Aligning Evaluation With Long-Term Supply Goals

Long-tail search behavior reflects this evaluation mindset. Buyers often search for phrases such as “titanium machining supplier for production,” “thin wall titanium machining stability,” “machining Ti-6Al-4V repeatability,” or “titanium machining services with inspection report.” Addressing these concerns directly aligns content with real procurement intent.

At YISHANG, we support buyers who prioritize repeatability and long-term supply stability. Our focus is on disciplined production execution—consistent process control, practical workholding design, and inspection timing that reflects free-state geometry. When geometry or tolerance targets create unnecessary risk, we provide DFM feedback early so procurement and engineering teams can make informed decisions before cost and lead time escalate.

What to Specify in an RFQ for Titanium Machining Services

For overseas buyers, RFQ clarity has a direct impact on pricing accuracy and production stability. Many titanium RFQs omit information that drives machining risk, leading suppliers to make assumptions that only surface during DFM or production.

Drawings should clearly identify critical features. In most assemblies, only a small number of dimensions control function—such as hole location to datums, flatness on sealing faces, or concentricity on rotating parts. Marking all dimensions as equally tight increases cost and reduces process margin.

Material definition should include grade and standard where applicable. For industrial supply chains, specifications such as ASTM B348 are commonly used for bars and billets. If traceability or batch separation is required, stating this early helps suppliers plan inspection and documentation.

Surface requirements should be tied to function. Cosmetic finishes and functional finishes are not processed the same way. For fatigue-sensitive parts, surface integrity matters more than a single Ra value.

Finally, volume expectations and delivery rhythm are essential. Titanium machining behavior changes with production planning. Knowing whether demand is a one-time batch or a repeating program allows suppliers to design tooling, inspection, and scheduling for stability.

Practical RFQ Information Buyers Commonly Include

| RFQ item | Why it matters in cnc titanium sourcing |

|---|---|

| Annual or batch volume | Drives tool-life strategy, fixture investment, and scheduling |

| Critical dimensions / datums | Focuses inspection and stability control where it matters |

| Material grade + standard | Supports traceability and reduces variation assumptions |

| Surface requirement intent | Prevents over-processing and unnecessary cost |

| Inspection expectations | Aligns measurement timing and reporting format |

Quality Evidence Buyers Can Ask For Without Slowing the Program

Wholesale buyers often want confidence without turning procurement into an audit project. The most effective evidence is typically lightweight: enough to confirm control, not enough to create friction. One example is first-article inspection (FAI) with clear datum strategy and measurement method. Another is a short-run capability snapshot on a critical feature, especially when tolerance is tight.

For recurring programs, buyers may also ask how the supplier handles traceability: batch labeling, material certificates, and separation of lots. These practices matter more for titanium than many buyers expect because titanium machining outcomes can be sensitive to material condition and batch variation.

When parts are distortion-sensitive, one of the most valuable pieces of evidence is the supplier’s approach to post-unclamp verification. A supplier who measures only while the part is constrained is not providing the information a buyer needs. A supplier who measures free-state geometry after stabilization is showing that they understand production reality.

Frequently Asked Questions Relevant to Volume Buyers

Why do titanium parts deform after machining even when inspected in tolerance?

Deformation usually comes from residual stress released after unclamping. Titanium can store elastic energy during machining, and the part may shift once constraints are removed.

Why are titanium machining prices inconsistent between suppliers?

Price gaps often reflect different assumptions about risk—tooling strategy, thermal control, monitoring, and scrap tolerance. Lower unit price can correlate with higher variability, which raises total cost after rework and delays.

Can titanium CNC machining be stable in long-term production?

Yes, when heat accumulation, tooling behavior, fixturing strategy, and inspection timing are managed as an integrated system.

What should I provide for an RFQ to get a realistic quote?

Clear drawings, tolerance priorities, surface requirements, material specification (e.g., grade and standard), and expected order volume help suppliers quote with realistic risk assumptions.

Conclusion

For overseas wholesale buyers, titanium CNC machining should be evaluated through the lens of stability, repeatability, and risk control. The practical question is not whether titanium can be machined, but whether it can be machined consistently across batches.

When heat accumulation, tooling behavior, fixturing strategy, and inspection timing are controlled as a system, titanium machining becomes predictable rather than risky. This system-level understanding separates suppliers who can deliver stable production from those who only succeed at the sample stage.

If you are sourcing titanium parts for ongoing production, sharing drawings, volume expectations, and critical requirements early will lead to more reliable outcomes. YISHANG supports overseas buyers with production-focused machining strategies designed to reduce risk and support long-term supply stability. We welcome inquiries to review feasibility and discuss a production-ready approach.