What Makes Tube Laser a Game-Changer in Metal Fabrication?

For many wholesale buyers, tube laser cutting has shifted from an idea to a necessity. It isn’t just a fabrication tool—it’s a system for precision, scalability, and cost control.

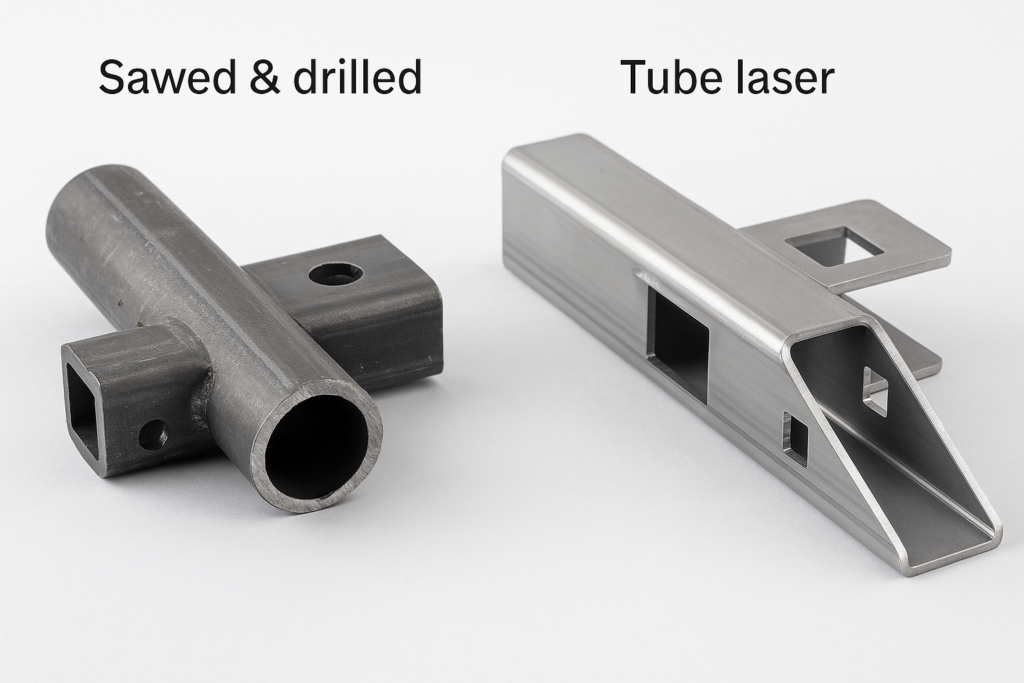

Traditional workflows like sawing, drilling, and punching introduce variability and slow down production. Precision tube laser cutting replaces these steps with a single pass, delivering tighter tolerances and alignment-ready parts with minimal finishing.

This directly impacts ready-to-assemble structures—like vending frames or custom laser cut metal signs—by enabling faster builds, fewer downstream errors, and more predictable delivery outcomes.

Why Global Buyers Prefer Fiber Laser Over CO2

A common question is: fiber laser vs CO2—what’s better for industrial pipe and tubing?

For buyers sourcing steel or aluminum components, fiber laser offers faster speeds, lower energy use, and better cutting accuracy for thin to mid-range materials. It’s ideal for laser cutting for metal tubes or aluminum laser cutting service—especially when dealing with tight tolerances or complex geometries.

And because Our system uses CNC-guided fiber laser cutting machines, we deliver superior cut-edge quality, minimal burrs, and consistent repeatability across batches.

A Clear Transformation: Before and After Tube Laser Integration

Consider a real case: A buyer sourcing support frames for commercial shelving. Previously, each frame required 12 minutes of assembly due to multiple setup steps: sawing, drilling, welding jigs, and hole alignment.

After converting to precision tube laser:

Tab-and-slot cuts reduced fixture needs

Weld points dropped by 60%

Assembly time fell to 4 minutes

| Metric | Pre-Laser Fabrication | Our Tube Laser System |

|---|---|---|

| Assembly Time | ~12 min/frame | ~4 min/frame |

| Weld Points | 6–8 | 2–3 |

| Rework Rate | 6.5% | <1% |

| Batch Deviation | Frequent | Nearly Zero |

The change wasn’t just about speed—it was about standardizing process steps, reducing reliance on skilled labor, and eliminating cross-stage inconsistencies.

Engineered for Assembly: From Laser Cut to Fit-Ready

Tube laser cutting isn’t just about slicing profiles—it’s about designing for frictionless assembly.

Using a Design for Laser Fabrication (DFLF) approach, our engineering team integrates bolt holes, interlock features, and etch marks into the laser path. This eliminates guesswork and makes field installation intuitive—even without skilled labor.

For OEMs outsourcing across borders, this minimizes installation variation and accelerates completion timelines.

Lowering Total Cost with Laser Accuracy

Often buyers ask: how does laser cutting work to cut costs?

It eliminates rework. Through ±0.1 mm precision and stable output, you reduce returns, avoid mismatched parts, and shorten QA inspection cycles.

It also increases packing efficiency. With identical parts and fewer weld brackets, units stack and ship tighter—cutting container costs and improving last-mile delivery.

Designing Stronger Connections with Less Welding

Smart geometry enables faster, stronger connections. Instead of welding every joint, laser-cut tabs and notches allow self-aligning assembly.

We use:

Saddle cuts for curved joins

Slot-and-tab joints for accurate box framing

Etched markings for intuitive alignment (great for cross-border kits)

It’s not just precision—it’s process intelligence embedded in the part itself.

Can It Cut Aluminum Pipe? And Other Buyer Questions

Yes. We offer an aluminum laser cutting service compatible with square and round profiles.

✓ Copper Cutting Capability

Whether cutting copper, stainless steel, or galvanized pipe, Our team handles profiles from 16 mm up to 120 mm diameter. Cutting copper on laser systems requires precise power calibration—our fiber machines are optimized for this.

✓ Stainless Steel Tube Bending

Need bending stainless steel tubing? We provide post-cut processing including mandrel bending for smooth, distortion-free curves. This is critical in applications like display frames, medical carts, or architectural tubing.

✓ Custom Laser Cut Sign Frames

Custom metal signs laser cut from aluminum and stainless? Absolutely. We process signage frames and support tubes for retail, commercial and architectural environments.

As for wall thickness, our fiber systems handle 1.0 mm to 5.0 mm smoothly, maintaining a clean edge and zero warping.

Predictability That Pays Off: ROI You Can Measure

Let’s put numbers to it:

Traditional method: 200 units = 40 hours assembly

Laser-cut with slots: 200 units = 13 hours

Saving: 27 hours + 5% material waste reduction

Assuming labor at $30/hour, that’s $810 in savings per 200 units—excluding shipping improvements from tighter packing. If you scale that to 2,000 units per month, the labor savings alone exceed $8,000.

This precision also enables predictive costing and fast quoting—essential for buyers managing tight POs and multi-country supply chains.

Whether for furniture kits, enclosure frames, or laser cut steel signs, repeatability ensures global compatibility.

FAQ: Practical Buyer Considerations

Q: Is laser tube cutting better than welding for light frames?

A: Yes, especially for aluminum or stainless tubing. Pre-cut tabs minimize welding and boost assembly speed.

Q: What materials can your team process?

A: 304/316 stainless steel, mild steel, aluminum, galvanized pipe, and copper.

Q: Can you offer aluminum laser cutting service?

A: Absolutely. Our fiber lasers excel in aluminum profiles with clean, oxide-free edges.

Q: Can you cut copper tubes or sheets?

A: Yes. Cutting copper on laser systems is supported through fine-tuned power and nozzle control.

Q: Do you provide stainless steel bending or tubing services?

A: Yes, including bending stainless steel tubing post-laser cutting for seamless structural parts.

Q: Is laser cutting cost-effective for small-to-mid runs?

A: Yes, particularly when including reduced rework, faster builds, and easier kitting.

Q: Can it cut both tubes and flat sheets?

A: Yes. Our CNC laser systems support both tube laser services and sheet metal components.

Q: Do you offer value-added services?

A: Coating, labeling, laser cut box packaging, sub-assembly, and palletized shipping are all available.

Final Word: Smoother Builds, Smarter Sourcing

Tube laser cutting isn’t just about precision—it’s about taking friction out of your sourcing workflow. When every hour saved on the shop floor translates into dollars saved on labor, freight, or turnaround time, consistency matters.

That’s what our tube laser system delivers: measurable results, faster builds, and fewer surprises.

Ready to explore a faster, cleaner way to source precision-cut tubing? Contact YISHANG today—we speak production fluently.