Why Stainless Steel Isn’t a One-Size-Fits-All Material (And Why That Matters)

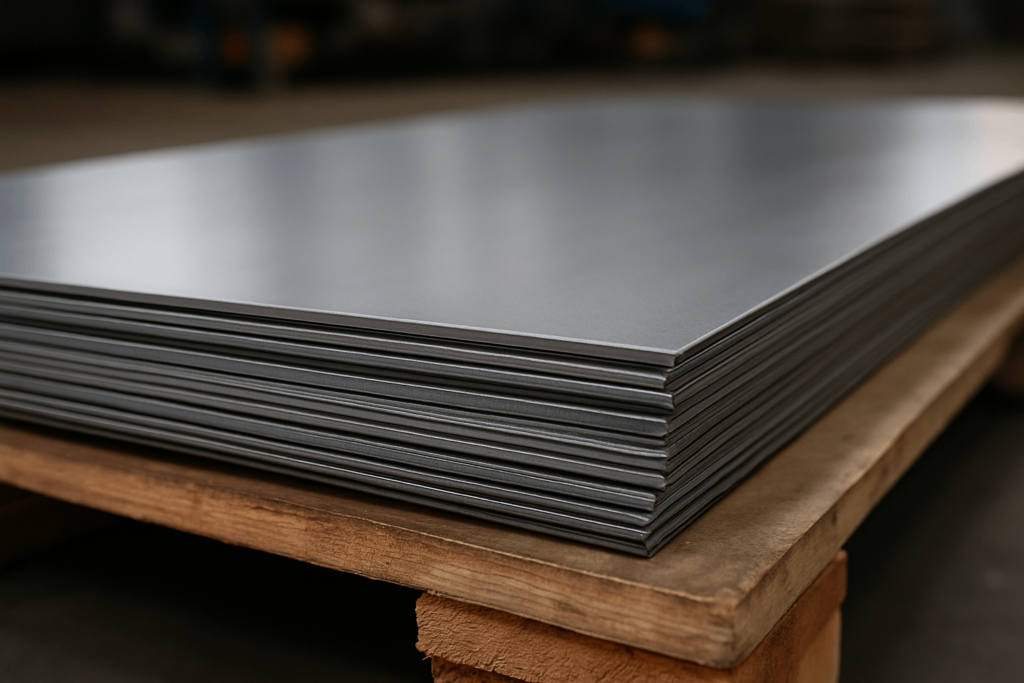

Stainless steel is a versatile material, but not all types perform the same in real-world environments. For wholesale buyers sourcing custom parts, the wrong material choice can result in surface degradation, premature failure, and inflated warranty claims.

At YISHANG, we’ve helped global buyers across 50+ countries minimize risk by choosing the right stainless steel for specific environments, industries, and cost structures. We are certified by ISO 9001 and RoHS, ensuring sourcing traceability across international markets. All materials comply with major international standards such as ASTM, EN, and JIS.

This guide is not just about grades—it’s about procurement logic, practical application, and decision-making efficiency.

From Alloy to Application: What Really Defines a Stainless Steel Type

The stainless steel market isn’t just about price—it’s about performance tied to composition. Every alloying element plays a role:

| Element | Function | Affected Properties | Typical Grades |

|---|---|---|---|

| Chromium | Forms passive layer | Corrosion resistance | All grades (≥10.5%) |

| Nickel | Stabilizes austenite | Ductility, weldability | 304, 316, 310 |

| Molybdenum | Chloride resistance | Pitting strength | 316, 2205 |

| Carbon | Increases hardness | Reduced corrosion resistance | 420, 440C |

| Nitrogen | Strength enhancer | Yield strength | Duplex grades |

This matters for procurement: a project requiring pressed sheet steel for coastal enclosures may need molybdenum-rich alloys, while low-cost indoor housings may perform well with ferritic alternatives and powder coating steel finishes.

We support both small-volume MOQ sampling and full-scale production, with consistent lead time control based on your delivery expectations.

Now that we’ve covered the chemistry and mechanical implications of alloy selection, let’s explore how these differences influence performance in real-world product categories.

Choosing Stainless Steel for Specific Applications

➤ Vending Machine Panels

Outdoor vending enclosures require stainless steel that resists fingerprinting, graffiti cleaning solvents, and UV damage. In most cases, 430-grade with a powder coat finish meets budget and environmental needs. For urban transit zones, 304 with a No. 4 finish or bead-blasted stainless steel works well for wear resistance and visual appeal.

YISHANG supplies custom sheet metal parts for OEM projects in the vending sector, helping buyers optimize between price, durability, and surface quality. All components are designed for long-life use with fast replenishment cycles.

➤ Food Equipment

Food-grade equipment must comply with sanitary standards, which makes 304 and 316L stainless steels essential. For applications like sink bowls, food contact panels, or enclosed prep stations, YISHANG offers brushed and electropolished finishes with full surface Ra compliance.

We provide wholesale stainless steel components engineered for food safety, easy cleaning, and NSF-compliant design support.

➤ Outdoor Housing Structures

Outdoor enclosures, lockers, and public-facing kiosk frames often suffer from climate-related wear. For these environments, YISHANG recommends duplex 2205 or specially coated 316 stainless steel. While 316 is known for its chloride resistance, duplex grades offer higher strength for wind-exposed or vandal-prone structures.

Clients working on public infrastructure in coastal or desert environments often choose powder-coated duplex stainless, ensuring extended outdoor performance with reduced touch-up frequency. These grades also offer excellent compatibility with forming, welding, and powder coating, making them suitable for complex housings and bracket assemblies.

YISHANG’s construction-sector partners value not only corrosion resistance, but also how these materials behave in fabrication. Our in-house team considers factors like laser cutting edge integrity, weld response, and bend radius variation across grades.

We provide both design consultation and quick-turn prototyping to help customers move faster from concept to delivery.

Understanding the Impact of Grade Selection on Cost and Durability

Making the right stainless steel choice has long-term implications for product durability and cost-efficiency. In many OEM projects, buyers must strike a balance between initial material cost, lifecycle performance, and post-processing compatibility.

For example, 304 stainless offers excellent overall resistance but may fall short in high-salinity zones—leading to increased maintenance or replacement costs. In contrast, 316 stainless delivers better long-term value for outdoor or marine-grade units despite a higher upfront price. YISHANG often supports clients in evaluating these trade-offs using application-based TCO (Total Cost of Ownership) comparisons.

We help clients assess alternatives that align with functional requirements while considering formability, powder coating potential, corrosion index (e.g., PREN value), and global compliance.

Additional Procurement Considerations: Fabrication, Lead Time & MOQ

Stainless steel is not just about performance—it’s also about process compatibility and supply chain reliability. Different grades behave differently during fabrication:

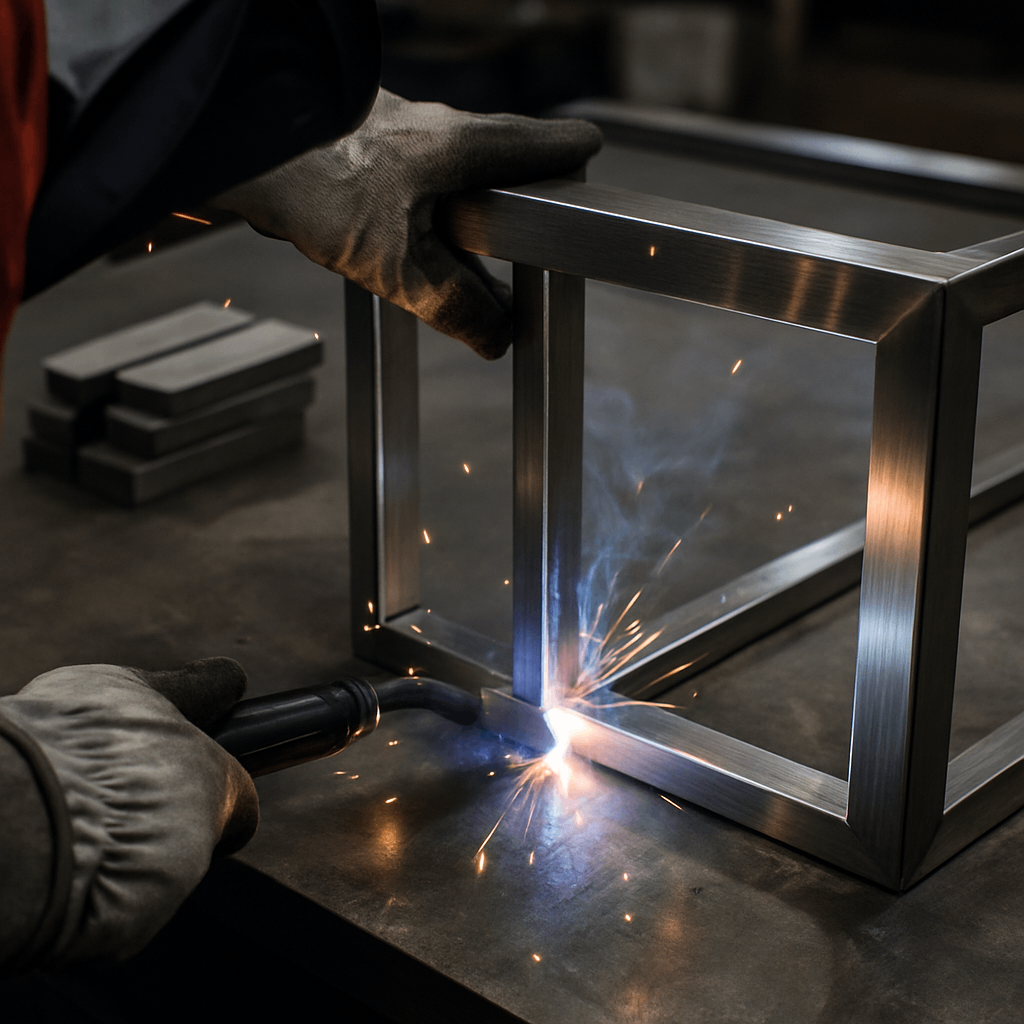

Austenitic grades like 304 and 316 offer excellent weldability and bending response, ideal for laser cutting and CNC punching.

Ferritic types like 430 may require slower feed rates during cutting and tighter bend radii.

Duplex stainless steels provide high strength but demand more controlled heat input during welding to prevent embrittlement.

At YISHANG, all materials are vetted for compatibility with laser cutting, bending, TIG/MIG welding, polishing, and powder coating. Our experienced team ensures your chosen material won’t create downstream problems during production.

We also support:

Low minimum order quantities (MOQs) for prototyping or new product development

Fast lead time options for time-sensitive procurement

Certification traceability for all materials, upon request

FAQ (Structured Data Recommendations)

Q: What’s the difference between 304 and 316 in marine use?

A: 304 stainless steel has general corrosion resistance but may pit in saltwater. 316 contains molybdenum, which increases chloride resistance and makes it suitable for coastal or marine exposure.

Q: Can stainless steel be powder coated for outdoor use?

A: Yes. With proper surface preparation and primer, powder coating for stainless steel provides an effective barrier for UV and moisture, extending durability.

Q: Do you support OEM/ODM orders with flexible volume?

A: Absolutely. YISHANG handles bulk orders and trial production with support in material selection, prototyping, and certification traceability.

Q: Are all your stainless steels compliant with global standards?

A: Yes. We work with materials that meet ASTM, EN, and JIS standards, and provide mill test certificates on request.

Whether you’re sourcing 304 stainless steel parts for retail display systems, or need duplex-grade structures for rugged environments, we provide a transparent path from prototype to mass production.

We’re ready to support your stainless steel selection. Contact YISHANG today to discuss your project requirements.