Introduction | Why B2B Metal Buyers Should Understand Vapor Polishing

In today’s B2B manufacturing landscape, metal enclosures often feature transparent plastic inserts—used for displays, monitoring panels, and access windows. These aren’t aesthetic flourishes; they’re mission-critical. Whether in EV chargers, telecom cabinets, or smart industrial systems, poor visibility can compromise both performance and user trust.

Vapor polishing—a controlled solvent-based process—restores optical clarity in CNC-machined plastics such as polycarbonate (PC) and acrylic (PMMA). For procurement teams sourcing metal assemblies with optical components, understanding this process is essential. It directly impacts compliance, field performance, and customer satisfaction.

This article outlines how vapor polishing works, when it’s required, and what wholesale buyers should evaluate when sourcing from suppliers like YISHANG.

Surface Quality as a Functional Specification

When Optical Clarity Becomes a Procurement Requirement

In B2B applications—especially for display enclosures in solar inverters, energy storage units, and control cabinets—optical plastic isn’t a design choice; it’s a performance specification. Glare, haze, or uneven polish can reduce readability, cause misinterpretation of data, or breach user interface safety standards.

That’s why many RFQs now specify haze levels below 5%, and light transmittance above 92%. If your enclosure window fogs or diffuses light poorly, the whole assembly can fail functional review—even if mechanical tolerances pass.

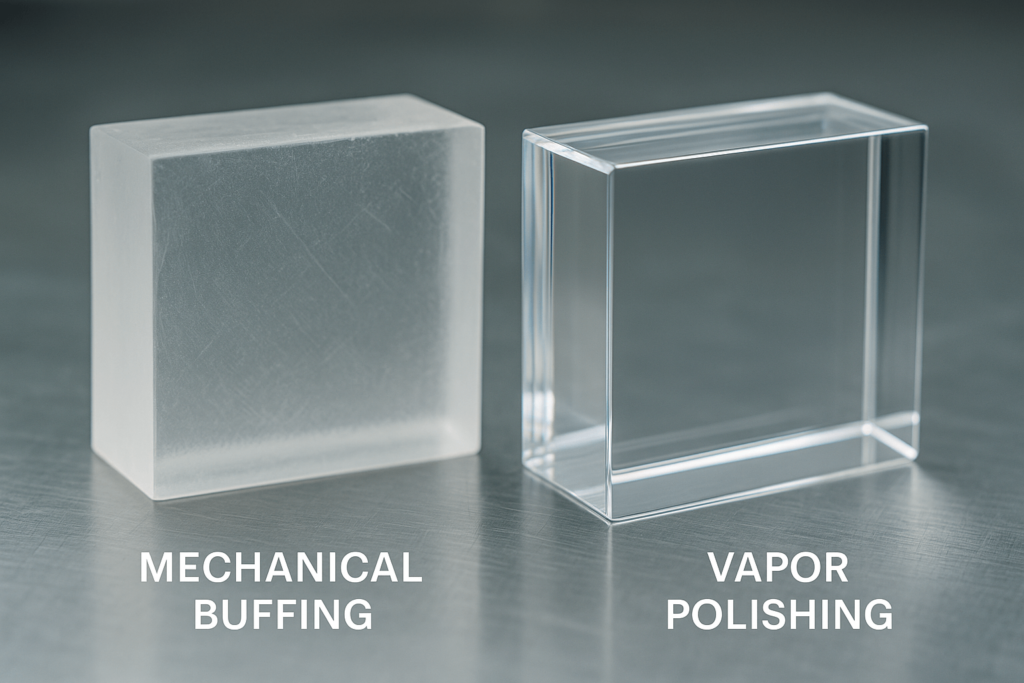

Vapor Polishing vs. Mechanical Buffing

While traditional mechanical polishing may suffice for basic edge finishing, it often fails with intricate geometries or parts requiring dimensional stability. Vapor polishing, in contrast, softens and reflows the plastic’s surface with solvent vapor—eliminating micro-scratches and tool marks.

It’s ideal for gasket-sealed, high-IP enclosures where clear visibility is vital and precision is non-negotiable.

Why CNC-Machined Plastics Appear Cloudy

Surface Damage from Milling

CNC processes leave behind machining lines, molecular stresses, and tool-induced haze on transparent plastics like PC or PMMA. Even if a part meets ±0.1 mm tolerance, poor light diffusion can result in a frosted appearance.

Such clarity issues are unacceptable in applications requiring LCD display visibility or barcode scanning.

Vapor Polishing as a Surface Reflow Solution

Vapor polishing exposes the plastic to a controlled solvent vapor (e.g., trichloroethylene). This relaxes the top molecular layer without melting the substrate, allowing it to reflow into a smooth, glass-like finish.

Unlike coatings or manual polishing, it doesn’t introduce foreign layers—ensuring long-term stability even under thermal cycling or UV exposure.

Vapor Polishing Process, Step-by-Step

Cleaning and Fixturing

Before vapor contact, parts must undergo ultrasonic cleaning to remove oils and static-bound particles. Fixturing then holds each part in position, ensuring uniform vapor flow across complex contours.

Any uneven exposure can result in cloud patches or inconsistent gloss. Buyers should confirm the supplier uses anti-static wipes and fixturing jigs compatible with the enclosure geometry.

Solvent Selection and Exposure Control

Commonly used solvents include methylene chloride and newer RoHS-compliant blends. Solvent choice depends on resin type, enclosure geometry, and surface area.

Exposure typically lasts under 10 seconds, but it must be consistent. Suppliers should control chamber temperature, humidity, and saturation levels to avoid over-processing.

Chamber Geometry and Polishing Consistency

Enclosures with deep cavities or thin ribs require vapor distribution modeling. If vapor is obstructed or stagnant, internal features may remain unpolished.

Ask your supplier if multi-surface polishing is validated using haze meter testing or LED spot checks. At YISHANG, all transparent parts undergo a 3-point QA check.

Post-Polishing Cooling and QA

After exposure, parts must cool in a cleanroom environment—typically under 40% RH. Warping or solvent retention can distort enclosure fitment or affect electrical sealing.

Procurement teams should request optical test reports, solvent compliance documentation, and dimensional re-check data.

Common Failures and Their Procurement Implications

Incompatible Plastics

Materials like PA66, glass-filled polymers, or high-impact blends may blister or crack under vapor polishing. Always validate the resin grade with your enclosure supplier.

At YISHANG, we provide resin verification certificates and simulate vapor impact in pre-production batches.

Dimensional Fitment Problems

In hybrid assemblies, a slight dimensional shift can block gasket compression or misalign sensor cutouts. This is especially true for IP65/IP66 enclosures with tight sealing margins.

Ensure your CAD model allows for post-polish expansion (typically +0.1 mm) or include a test iteration before mass production.

Variability Between Batches

Without process automation, results may vary across batches. Differences in operator timing, chamber loading, or solvent freshness can introduce visual defects.

Always ask whether the vendor uses automated vapor delivery and tracks polishing parameters per part ID.

When to Specify Vapor Polishing in Enclosure Projects

Use-Cases That Justify It

Vapor polishing is warranted when:

- The plastic part functions as a display window or status panel

- Light transmission >90% is required for user interaction

- The product targets export-grade or high-visibility applications

Applications like EV charging stations, public kiosks, or HMI modules are common use cases.

Simulation Before Tooling Lock-in

Before mass production, run a simulated fit check post-polishing. Your CAD team can offset critical dimensions or define buffer zones.

Some buyers request a 3D-printed prototype + vapor polish sample for QA baseline definition.

ROI Justification

Although vapor polishing adds 2–5% to enclosure cost, it reduces field failures, inspection rejects, and cosmetic returns. This makes it a cost-effective investment in premium assemblies.

Design and Supplier Coordination Tips

Design Guidelines for Polished Inserts

- Avoid tight mechanical press fits post-polish

- Add at least +0.1 mm clearance in clamping zones

- Use silicone or foam gaskets compatible with reflowed surfaces

This reduces assembly stress and maintains enclosure IP ratings.

What to Ask Your Supplier

Key questions to include in RFQs:

- What polishing solvents do you use?

- Are RoHS or REACH certifications available?

- Do you have haze or transmittance test reports?

- How do you ensure cavity consistency in multi-surface parts?

At YISHANG, we provide batch-level QA reports and optical data upon request.

Integrated QA and Packaging

Ensure your supplier performs post-polish QA before shipping. Also, request soft-touch packaging and scratch-free handling for polished surfaces.

Industry Trends and Engineering Shifts

Sustainability Regulations and Solvent Recovery

Stricter EU/US regulations have forced a shift to enclosed polishing systems with >90% solvent recovery. This supports ESG goals and reduces VOC emissions.

Suppliers using closed-loop chambers also report higher finish consistency.

Process Automation and Inline Inspection

Leading vendors now implement robotic polishing arms and haze meters on the production line. This reduces operator dependency and supports full QA traceability.

At YISHANG, we’re upgrading to inline LED clarity verification by Q2 2026.

Composite Surface Finishes

In ruggedized products like telecom junction boxes, vapor polishing is combined with hard coats or anti-UV films. This extends clarity in high-sunlight or scratch-prone deployments.

Quick Procurement Checklist for Vapor-Polished Enclosure Buyers

- Confirm material compatibility with vapor solvents

- Request RoHS-compliant solvent documentation

- Ask for haze/transmittance test reports

- Validate fixturing plans for complex enclosures

- Simulate fit post-polish in CAD

- Confirm batch-level QA and visual inspections

Conclusion | Strategic Use of Vapor Polishing in Metal Assemblies

Vapor polishing isn’t just about aesthetics—it’s a functional step in precision enclosure design. It enhances display visibility, strengthens product credibility, and reduces post-shipment QA friction.

For buyers working with plastic-integrated metal assemblies, especially in smart devices or export-grade systems, vapor polishing is a value-adding option.

At YISHANG, we engineer metal enclosures to accommodate vapor-polished plastics with precision. Our team supports resin selection, fixture design, and optical QA.

Send your inquiry today and reduce your failure rate before your next shipment leaves port.

FAQ

Q1. Is vapor polishing suitable for polycarbonate enclosures?

Yes. PC and PMMA both respond well. Ensure part geometry allows full vapor access.

Q2. Will polishing affect metal part fitment?

Yes. Expect minor expansion—design with clearance and validate with test runs.

Q3. What’s the MOQ for polished enclosures?

At YISHANG, we offer low-volume trials and flexible order runs.

Q4. Can internal cavities be vapor polished?

Yes, if fixturing and chamber airflow permit consistent vapor contact.

Q5. Can I get haze/clarity data for compliance audits?

Yes. We provide haze %, transmittance, and LED readability reports for OEM buyers.