When procurement managers, engineers, and industrial buyers evaluate materials, they are not simply curious about what aluminum is used for at a basic level. They want to know whether this metal can support structural safety, stable quality in batch production, predictable lead times, and long-term performance in demanding environments. For a metal products company and its customers, aluminum is not just an element on the periodic table. It is a business-critical decision that affects product reliability, warranty risk, logistics cost, and total manufacturing budget.

Many online articles list common aluminum applications or show familiar things made from aluminium, but they rarely go further. They do not explain how aluminum behaves in fabrication, where its limitations appear, or why some projects use it successfully while others fail. For overseas wholesale buyers, this lack of depth makes it hard to judge if aluminum is the right choice for their projects, and whether a supplier truly understands industrial requirements.

This article takes a different approach by looking at aluminum from the perspective of engineers and sourcing managers. We link key aluminum properties to real functional requirements, explain the most common uses of aluminium in industry, and point out where aluminum may not be the best fit. The purpose is practical: to support better decisions when you prepare RFQs, develop drawings, or choose between aluminum, steel, and other materials. The insights reflect YISHANG’s hands-on experience working with aluminum sheet metal, CNC-machined parts, and custom industrial assemblies for global buyers.

Why Aluminum Keeps Winning: The Engineering Logic Behind Its Uses

Before asking what can aluminum be used for in detail, it helps to understand why aluminum keeps appearing in modern industrial designs. Its popularity is not an accident or a temporary trend. It comes from a combination of measurable advantages: weight reduction, corrosion behavior, thermal performance, manufacturability, and sustainability. Each of these links directly to sourcing concerns such as transport cost, lifecycle risk, energy consumption, and process stability.

Lightweight Strength Without Structural Compromise

From an engineering point of view, one of the most important uses of aluminium is in structures that must remain strong but cannot be heavy. Aluminum has an aluminium density of about 2.7 g/cm³, roughly one-third that of carbon steel. At the same time, common alloys such as 6061-T6 offer tensile strengths near 290 MPa, and high-strength grades like 7075-T6 can exceed 500 MPa. For many machine frames, equipment supports, and industrial racks, this ratio of strength to weight is more attractive than either steel or plastic.

For buyers, this means a frame or enclosure made from aluminum will be easier to move, assemble, and install. Shipping costs are reduced, especially for bulky structures. Lighter components also put less load on actuators, bearings, and guide rails in automated systems, which can extend service life and lower maintenance. When you see aluminum structural components in automation lines, modular workstations, or equipment housings, it is usually because the combination of “strong enough” and “light enough” leads to better total cost of ownership than heavier alternatives.

Corrosion Resistance and Predictable Long-Term Behavior

Another key reason aluminum is chosen in industrial projects lies in the chemical properties of aluminum. The metal naturally forms an oxide layer when exposed to air. This layer acts as a barrier, protecting the underlying material from further reaction. In practical terms, that means aluminum can withstand moisture, many chemicals, and outdoor exposure better than uncoated steel.

For buyers sourcing outdoor cabinets, telecom boxes, medical device housings, or equipment used in coastal regions, corrosion is not a small detail; it is a major failure risk. Choosing aluminum instead of standard steel reduces the need for heavy coatings and extends service life. When combined with anodizing or powder coating, aluminum enclosures can run for many years with minimal maintenance. This predictable aging behavior is one of the main uses of the element aluminum in real industrial environments, and a strong reason why aluminum is important in harsh or variable conditions.

Manufacturing Flexibility for Diverse Production Requirements

In procurement, a material is only practical when it works with real manufacturing processes. Aluminum is unusually flexible in this sense. It can be laser-cut, punched, bent, stamped, CNC machined, drilled, tapped, welded, riveted, and extruded with stable results. This makes it ideal for OEM and ODM projects where drawings combine sheet metal, structural profiles, and machined features in a single assembly.

From a factory’s point of view, aluminum bends with controlled springback when the correct inside radius and grain direction are used. CNC machining of aluminum allows faster cutting speeds than steel and produces clean surfaces with less tool wear. Welding requires proper preparation of the oxide layer and careful control of heat input, but once parameters are validated, production can be repeated with good consistency. For industrial buyers, this means aluminum supports a wide range of geometries and volume levels without introducing unnecessary process risk, which is why many aluminum industrial uses are linked to custom, complex assemblies.

Sustainability and Low-Carbon Procurement Alignment

Finally, aluminum supports sustainability goals. Recycled aluminum retains the same metallurgical characteristics as primary aluminum but requires up to about 95% less energy to produce. For buyers serving markets with strict environmental reporting—such as the EU or North America—this makes aluminum an effective material for balancing performance with carbon footprint. When you see specifications referencing recycled content, low-carbon materials, or circular supply chain strategies, aluminum is often part of that discussion and remains a practical way to support both engineering and ESG requirements.

What Aluminum Is Actually Used For — Explained by Function, Not Industry

Most buyers do not think in terms of “aluminum in aircraft” or “aluminum in buildings” when they prepare a project. They think in terms of functions: “I need a frame”, “I need a sealed enclosure”, “I need a heat-dissipating body”, “I need a precise moving part”. A more useful way to understand aluminum applications is by these functional roles. This approach also allows you to compare aluminum fairly against steel, stainless steel, plastics, and composites in each function.

Structural Frameworks and Load-Bearing Assemblies

In structural roles, aluminum is often chosen where loads are moderate but size is large. Typical examples include machine frames, equipment stands, workstations, modular racks, and supporting arms for displays or scanners. In these cases, using steel would make the structure unnecessarily heavy, while using plastic would compromise rigidity.

For buyers, the structural use of aluminum influences cost and logistics in several ways. Lighter assemblies reduce shipping weight; installers can assemble systems more quickly on site; and dynamic equipment experiences less stress during operation. At the same time, aluminum profiles or welded structures still maintain enough stiffness for most industrial loads. When the design is correctly engineered, aluminum frames do not feel “soft” or unstable in use, even though the mass is much lower than a similar steel design.

Aluminum also supports extruded profiles with built-in channels, alignment slots, and mounting features. This allows design engineers to integrate cable routing, panel mounting, and accessory installation into the frame itself. From a procurement perspective, that can reduce part count and simplify assembly, making aluminum attractive not just as a material, but as a design platform for structural systems. These are not consumer-grade aluminum uses in everyday life, but critical industrial uses where structure and efficiency must be balanced.

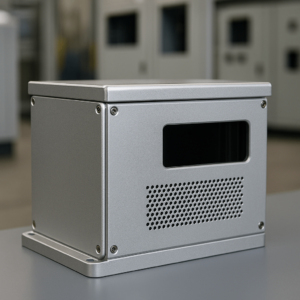

Protective Shells and Mechanical Enclosures

Another major set of uses of aluminum metal lies in protective shells. Enclosures for electrical components, electronics, control panels, medical devices, and vending systems have several conflicting needs. They must be rigid enough to protect internal parts, corrosion-resistant, thermally stable, visually acceptable, and economical to manufacture in batch quantities.

Aluminum meets these needs very well. It is a solid metal with good stiffness, and it does not crack easily if bending parameters are correctly set. The natural oxide layer and optional surface treatments such as anodizing or powder coating provide long-term corrosion protection. This means your enclosure can be used indoors, outdoors, or in semi-harsh environments without critical degradation. At the same time, aluminum can be cut, punched, and bent in standard sheet metal lines, which keeps per-unit cost under control even in mid-volume orders.

From a buyer’s point of view, specifying aluminum for enclosures improves both reliability and brand presentation. A well-designed aluminum box or housing feels more substantial than plastic and ages better in service. For OEM products that carry your customer’s logo, this difference is often worth the slightly higher material cost and explains why so many things made from aluminium in industrial contexts are actually enclosures and housings.

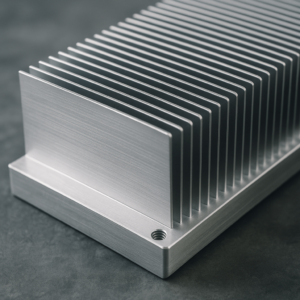

Heat Management Systems and Thermal Structures

As power output rises in electronics, batteries, inverters, and lighting systems, heat becomes a core design constraint. Poor thermal management can shorten component lifespan and trigger preventable failures. Because of this, one of the most valuable uses of aluminium in industry is its role as a reliable heat-spreading material.

Aluminum conducts heat quickly, but its contribution depends on how it integrates into the system. In heat sinks, aluminum allows designers to form dense, lightweight fins that expand surface area without adding unnecessary mass. These fins pull heat away from chips or modules and release it efficiently, which helps stabilize performance even under sustained load.

In EV battery packs and energy-storage platforms, aluminum plays a different role. Here, designers rely on aluminum cooling plates or structural housings to move heat while also handling road vibration, shock, and daily environmental exposure. Its mix of rigidity, conductivity, and corrosion resistance helps these components maintain stable temperatures throughout the duty cycle.

In LED modules, aluminum again adds value. The housing often acts as both the mechanical frame and the thermal path, eliminating the need for separate cooling elements. By pulling heat away from the diodes and releasing it into the surrounding air, aluminum improves reliability and reduces part count—two reasons it remains a preferred choice in modern lighting and electronics.

For buyers, the practical question is not “is aluminum a solid?” or “what type of element is aluminum?” but rather “can this material keep my system within safe temperature limits under real load?” In many cases, aluminum offers the best balance of performance, cost, and manufacturability for that requirement, making it one of the most important uses of aluminium in modern products.

Precision CNC Components and Tight-Tolerance Industrial Parts

CNC-machined aluminum parts are widely used in brackets, fixtures, sensor mounts, camera housings, instrument frames, and motion system components. The reason is simple: aluminum machines quickly and cleanly. It produces consistent chips, allows sharp edges and detailed geometries, and supports tight tolerances when the machining strategy is correct.

For procurement managers, this has several implications. First, cycle time on CNC machines is shorter with aluminum than with many steels, which directly reduces machining cost per part. Second, tool life is usually better, which stabilizes cost in longer-term supply agreements. Third, finished aluminum surfaces are suitable for many applications even before additional finishing, which can simplify processing and shorten lead time.

When buyers request quotes for complex machined parts, suppliers will often recommend 6061 or a similar alloy because it balances strength, machinability, and cost. These practical considerations are part of real-world aluminum industrial uses that do not always appear in generic materials guides but matter a lot in daily sourcing decisions.

Lightweight Moving Parts for Motion-Driven Systems

In systems with sliding, rotating, or reciprocating motion, the mass of moving parts directly affects performance. Heavy components require more energy, produce more wear, and can reduce acceleration and positioning accuracy. Using aluminum for plates, arms, carriers, and guards in motion systems can significantly reduce these loads and improve system efficiency.

From a sourcing point of view, the benefit is long-term. Lighter aluminum parts reduce the stress on motors, gearboxes, and bearings. Over time, this can lower service frequency and reduce unscheduled downtime. For buyers who supply equipment into competitive markets, this kind of reliability is a real selling point—and material choice is part of what makes it possible. In this sense, some of the most valuable uses of aluminium metal are not visible to the end user, but deeply influence how the machine behaves over years of operation.

Aesthetic and Human-Touch Surface Components

Although industrial projects are not primarily about looks, appearance still matters for many applications: operator panels, visible housings, architectural elements, and any surface the end user will touch. Aluminum responds well to brushing, polishing, bead blasting, and anodizing. The result is a surface that looks professional and feels solid in the hand.

For B2B buyers, this offers an option that sits between plastic and stainless steel. Aluminum can provide a high-end finish without the weight or cost associated with full stainless steel construction. As a result, many “front-of-house” covers, bezels, and trims in industrial equipment are now made from aluminum, even when the internal structure uses other materials. This is where what aluminum looks like—a silvery, clean, modern surface—becomes part of the product’s perceived quality.

When Aluminum Is the Wrong Choice — Realistic Limitations Buyers Must Consider

No material is perfect. A supplier that presents aluminum as the answer to every design problem is not being realistic. Knowing where aluminum does not perform well is essential for avoiding redesigns, failures, and hidden costs later in the product lifecycle.

Unsuitable for High-Temperature Environments

Although aluminum is a solid metal at room temperature and performs well in typical industrial conditions, its mechanical strength decreases significantly at elevated temperatures. For components exposed to continuous high heat—such as furnace linings, combustion chambers, or hot process tooling—aluminum cannot provide reliable structural performance. Even well below its melting point, aluminum will lose stiffness and yield strength as temperature rises.

For buyers, this means that any application involving sustained high temperatures or rapid thermal cycling requires careful evaluation. If the design involves direct flame, red-hot surfaces, or heavy thermal shock, alloys specifically designed for high-temperature service will be more appropriate than aluminum. Treating aluminum as a universal solution in such environments can lead to premature failure and safety issues.

Vulnerable to Heavy Abrasion or Repetitive Impact

In abrasive or impact-intensive environments, aluminum’s relatively low hardness becomes a problem. While it is not “soft” in a casual sense, it does wear faster than hardened steel. Applications involving bulk materials, stone, sand, or metallic abrasion will quickly damage aluminum if it is used as the primary wear surface.

This is why chute liners, certain impact plates, and mining or quarry equipment rarely rely on aluminum. Industrial buyers evaluating such applications should treat aluminum as an option for structural parts around the wear zone, not for the wear zone itself. Combining aluminum frames with localized steel wear plates is often a better approach and reflects a realistic understanding of what aluminum does well and where it must be supported by other materials.

Insufficient Stiffness in Certain Structural Scenarios

Although aluminum has good stiffness for its weight, some large machine bases, metrology structures, and heavy load platforms require higher stiffness than aluminum can provide in practical section sizes. In these cases, steel or composite designs may be more appropriate.

For buyers, the key is not to view aluminum as weak, but to recognize its stiffness limits in very demanding structural applications. If a design requires extremely low deflection under heavy load, and weight is not a primary concern, steel will often be the safer choice. A clear understanding of these stiffness constraints enables better decisions on when to use aluminum and when to specify alternative materials.

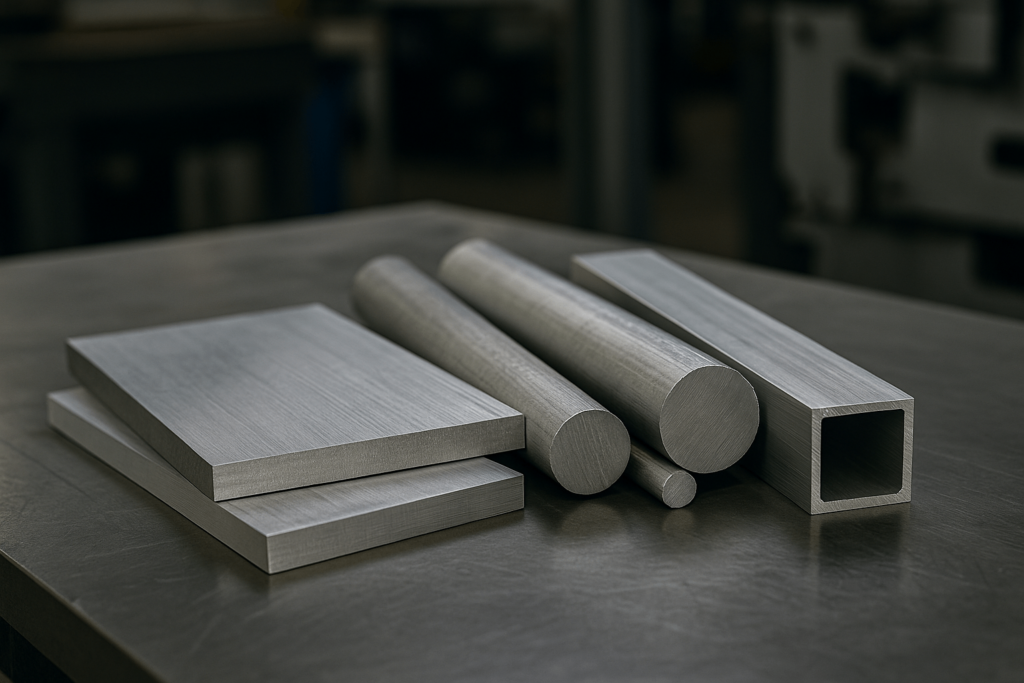

How Engineers and Procurement Teams Choose the Right Aluminum Alloy

Once aluminum has been chosen as a material class, the next question is which alloy and temper should be specified. Many RFQs simply state “aluminum” without further detail, which can lead to misunderstandings and sub-optimal results. A more effective approach is to link alloy selection to function, fabrication method, and required performance.

Mechanical Criteria and Strength Expectations

Different alloys provide different combinations of strength, formability, and toughness. A simplified comparison looks like this:

| AlloyTensile Strength (MPa)Key TraitsTypical Uses | |||

|---|---|---|---|

| 5052 | ~210 | Excellent bending and corrosion resistance | Enclosures, bent panels, covers |

| 6061-T6 | ~290 | Strong, machinable, weldable | Structural parts, CNC machined parts |

| 6063 | ~190 | Highly extrudable, smooth profiles | Architectural and structural profiles |

| 7075-T6 | 500+ | Very high strength, lower weldability | High-load precision components |

Buyers should consider: What loads will the part see? Does the design need extra margin for safety? Will parts be bent or machined more than once? By answering these questions early, you avoid overspecifying expensive alloys or underspecifying in critical locations. This is where practical knowledge of different aluminum specifications and alloy behaviors becomes a direct advantage in sourcing.

Compatibility With Fabrication Processes

The chosen alloy must align with the planned fabrication method. For instance, suppliers often select 5052 for bent sheet parts because it tolerates tight radii without cracking. Many CNC-machined and welded frames use 6061-T6 due to its balanced strength and machinability. For extrusion projects, 6063 remains popular because it forms clean, precise profiles.

Procurement managers can simplify this selection process by sharing the expected fabrication steps with their supplier. When the manufacturer understands whether parts will be laser-cut, bent, machined, or extruded, they can recommend alloys that achieve the required performance while avoiding production issues. This cooperation reduces trial-and-error and helps keep projects running on schedule.

Surface Finish Requirements

Surface finishes are not just cosmetic. They affect corrosion resistance, scratch resistance, and how dirt or fingerprints show over time. Aluminum supports anodizing for hard and decorative coatings, powder coating for thicker protective layers, brushing or polishing for visual effect, and bead blasting for uniform matte finishes.

If your customer requires a particular look or performance standard, that requirement should be discussed early in the sourcing process. It may influence both alloy choice and process sequence. Understanding what aluminum looks like under different finishes helps set realistic expectations for appearance and durability.

Cost, Geometry, and Lifecycle Considerations

Finally, total cost is determined by more than raw material price. Bending radius, tooling needs, machining time, tolerance targets, and finishing steps all add or reduce cost. In many projects, aluminum provides a better balance of ease of fabrication and service life than alternative materials. By reviewing design, alloy, and process together, buyers and manufacturers can arrive at a solution that meets performance requirements without over-engineering the part.

Quick Property and Specification Reference for Industrial Buyers

For buyers who also need to answer basic specification questions, a quick technical summary can be useful. While aluminum’s behavior in real projects is more important than theory, a few fundamentals often appear in documentation and customer questions.

- What is aluminium?

Aluminum is a metallic chemical element with the symbol Al and atomic number 13. It belongs to group 13 of the periodic table, which is why you may see references to the aluminum group number or aluminium group number in technical documents. - Is aluminum a solid? What type of metal is aluminium?

At room temperature, aluminum is a solid, non-ferrous metal. It is generally classified as a lightweight structural metal rather than a heavy or precious metal. - Is aluminium an alloy or pure element?

Pure aluminum exists, but most industrial uses of aluminum involve alloys—combinations of aluminum with small amounts of other elements such as magnesium, silicon, or zinc. These alloys improve strength, hardness, or other properties. - Aluminum chemical formula and appearance

The aluminum chemical formula as an element is simply Al. In appearance, aluminum is typically a silvery-white metal with a relatively bright surface when freshly machined or polished. - Where is the element aluminum found?

In nature, aluminum is mainly found in bauxite and similar ores in the Earth’s crust. Industrial aluminum is produced from these ores and then processed into sheets, plates, extrusions, castings, and other forms before becoming finished parts.

For industrial buyers, these basics are often enough to answer customer questions without turning a sourcing discussion into a chemistry lesson, while still covering key long-tail queries like what type of element is aluminum and where is the element aluminum found.

The Future Roles of Aluminum in Modern Product Design

Looking ahead, aluminum will continue to play an important role in making products lighter, more efficient, and more sustainable. For buyers, understanding these trends can help align sourcing strategies with future market expectations and make sure today’s material choices will still make sense in the next product generation.

Smarter Lightweight Frameworks for Automation and Robotics

Automation and robotics systems are becoming more modular, more compact, and more energy-efficient. Aluminum supports these changes because it offers enough stiffness to keep assemblies precise while keeping mass low. A lighter frame requires smaller motors and actuators, which can reduce cost and simplify control.

Extruded aluminum profiles with built-in slots and channels make it easier to add sensors, route cables, and reconfigure assemblies over time. For OEM designers, this flexibility allows product lines to evolve without redesigning the entire mechanical structure. For procurement, it creates a stable, repeatable material choice that can cover multiple product generations. In this context, the application of aluminium is not limited to single parts but extends to platform-level design strategies.

Aluminum in Battery, Energy, and Thermal-Critical Systems

As electric vehicles, energy storage systems, and high-power electronics grow, the role of aluminum in thermal-critical structures becomes even more important. Aluminum can act as a protective housing, a structural support, and a heat path in the same component. Battery trays, cooling plates, inverter housings, and power distribution enclosures all benefit from this multi-role capability.

For buyers, this means aluminum is no longer just a frame material; it is part of the functional core of many new-energy products. Choosing the right aluminum solution early in a project can simplify certification, improve performance, and support long-term serviceability. These forward-looking aluminum applications will likely become standard expectations rather than special features.

Growth of Recycled and Low-Carbon Aluminum for Sustainable Supply Chains

Finally, as more customers ask for proof of environmental responsibility, recycled aluminum and low-carbon production routes are becoming part of standard procurement specifications. Aluminum’s ability to be recycled without losing core properties gives it a significant advantage over materials that degrade with each reuse.

For global buyers, working with suppliers who understand and can document recycled content levels is becoming a competitive necessity. Aluminum is well positioned to support that shift, combining industrial performance with credible sustainability data. This trend reinforces why aluminum is important beyond immediate engineering performance and connects material choice to brand image and regulatory compliance.

Conclusion — Aluminum Earned Its Place in Modern Manufacturing

Aluminum is used so widely today not because it is fashionable, but because it solves real engineering and sourcing problems. It combines lightweight strength, corrosion resistance, thermal performance, and fabrication flexibility in a way that fits modern industrial requirements. For uses of aluminium metal in frames, enclosures, CNC components, heat-dissipation structures, and motion systems, it often delivers the best balance of performance, manufacturability, and total cost.

For overseas buyers working with metal products and custom assemblies, the key is not just asking “what is aluminum used for?” but asking “does aluminum match the functional and manufacturing needs of this specific project?” When the answer is yes, aluminum can provide stable quality in batch production, lower logistics cost, and long-term reliability in the field.

If you are considering aluminum for your next OEM or industrial fabrication project and want engineering-oriented feedback on material selection and manufacturability, YISHANG can support you from concept to production.

Send us your drawings or requirements, and our team will help you evaluate practical options.