Why 18/10 Stainless Steel Matters for High-Volume Overseas Procurement

In global manufacturing, the difference between a successful procurement and costly rework often comes down to one detail: material grade. For many international bulk buyers, 18/10 stainless steel represents the benchmark for corrosion resistance, aesthetic quality, and processing reliability. But what does 18/10 stainless steel actually mean in real-world production? And how does it stack up against alternatives like 18/10 stainless steel vs 18/8 or standard 304 stainless steel?

18/10 stainless steel contains 18% chromium and 10% nickel. The chromium provides corrosion protection; the nickel adds formability and a bright finish. On paper, it’s a variant of 304 stainless steel—but in procurement terms, the specific composition impacts everything from polishing quality to international compliance.

For purchasing teams handling tens of thousands of fabricated components annually, these percentages aren’t just numbers. They directly affect pass rates, surface uniformity, and weld distortion.

💡 Procurement Pitfall Snapshot

Not all 304 stainless is 18/10. In 2023, a buyer failed QC when a supplier delivered 304-grade material with only 7.5% nickel content. The result: early corrosion and a failed EU food-contact audit.

Composition and Classification: What Is 18/10 Stainless Steel?

Breaking Down the Alloy

While often used as a shorthand for “premium stainless,” 18/10 is technically a high-nickel form of AISI 304 stainless steel. Its composition generally aligns with international standards:

| Element | Percentage Range |

|---|---|

| Chromium | 17.5–19.5% |

| Nickel | 8.0–10.5% (compare nickel content in 304 vs 18/10 for fabrication-grade selection) |

| Carbon | ≤ 0.08% |

| Manganese | ≤ 2.0% |

| Iron | Balance |

Global Standards Alignment

ASTM A240 / AISI 304 (U.S.)

EN 1.4301 (Europe)

GB/T 3280 / 06Cr19Ni10 (China)

So, what is 18/10 stainless steel from a buyer’s perspective? It’s a signal of higher polish, better formability, and often tighter quality tolerances. In simple terms, 18/10 stainless steel means the alloy contains around 18% chromium and 10% nickel, giving it superior corrosion resistance and appearance compared with 18/8 stainless or generic 304.It’s frequently compared to:

18/8 stainless steel vs 18/10: The 2% nickel difference improves corrosion resistance and deep draw performance.

304 stainless steel vs 18/10: All 18/10 falls under 304 grade, but offers better weldability and post-processing finish.

Fabrication Realities: Why 18/10 Excels in Production (Ideal for OEM Stainless Steel Fabrication)

Procurement teams often compare 18/10 stainless steel vs 304. While all 18/10 is technically part of 304, the extra nickel provides better weldability, smoother polishing, and more reliable performance in food-grade equipment.

In large-scale sheet metal manufacturing, material choice affects efficiency. At YISHANG, we’ve fabricated over 500,000 OEM units using various stainless grades. 18/10 continues to outperform its counterparts in three key ways:

Cutting and Shaping

Laser Cutting: Smoother, cleaner edges with fewer burrs.

Deep Drawing & Bending: Higher ductility reduces tearing, even at tight radii.

Punching: Longer tool life due to reduced work-hardening.

Welding & Assembly

18/10 offers a wider welding window and better post-weld appearance than lower-nickel 304 or 201 steel. It’s compatible with:

TIG/MIG welding

Spot welding for frames and cabinets

Laser welding in clean-edge applications

Finishing Consistency

Whether brushed, mirror-polished, or powder-coated, 18/10 maintains a uniform grain and color. This is especially valuable for buyers ordering modular product lines where color or texture mismatch across batches can be a deal-breaker.

Sanitary-Grade Equipment: Where 18/10 Truly Excels

18/10 stainless steel’s smooth finish, high corrosion resistance, and cleanability make it ideal for all sanitary environments, including foodservice, medical, and high-hygiene retail infrastructure.

Unified Hygienic Applications

Whether in a hospital, commercial kitchen, or customer-facing retail environment, 18/10 offers the same core benefit: non-contaminating, easy-to-sterilize surfaces that maintain structural integrity under aggressive cleaning cycles.

Common use cases:

Sinks, surgical carts, and food-prep tables

Sterile cabinets and cleanroom-compatible shelving

Outdoor lockers and vending machine frames in humid climates—making it ideal stainless steel for vending machines

All are compliant with FDA, LFGB, EN food-contact regulations and deliver superior lifecycle value.

This is why food-service buyers often ask: what is the best stainless steel for food use? The answer is usually 18/10, because it is durable, hygienic, and easy to sterilize.

Common Buyer Risks and How to Avoid Them

Material Substitution

Some overseas suppliers may deliver low-nickel alternatives under the 18/10 label—often not maliciously, but due to local grade interpretation differences. Still, the consequences can be serious:

Increased corrosion

Lower weld quality

Shortened lifespan

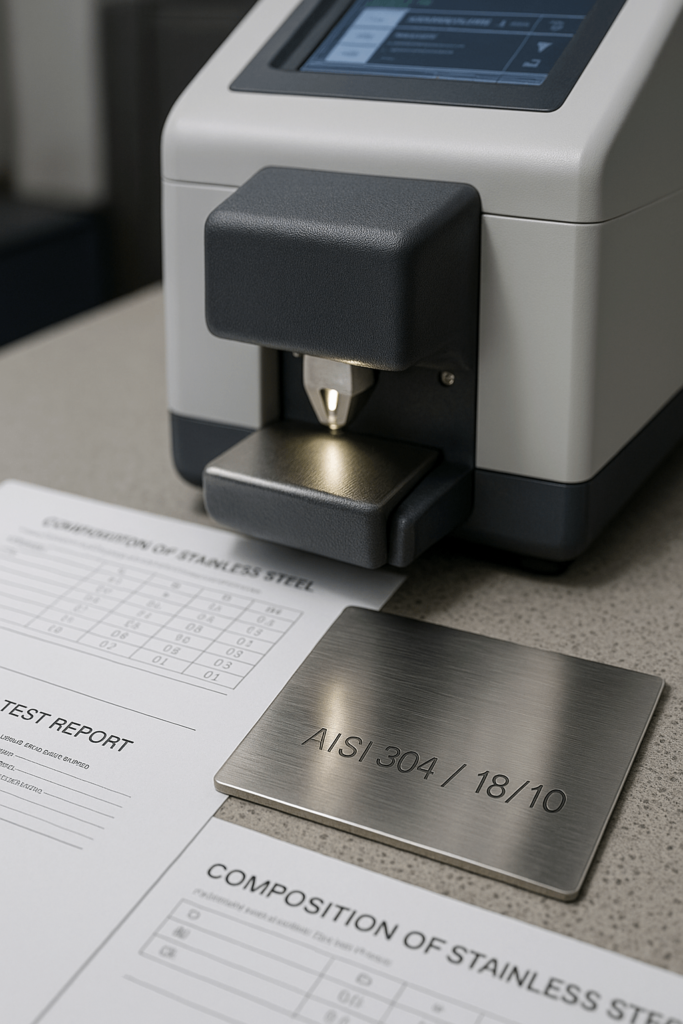

Mitigation: Always request mill test certificates (MTCs) and perform spectrometry sampling.

Surface Finish Inconsistency

Across large orders, uncontrolled polishing and passivation lead to uneven textures.

Procurement Tip: Define surface finish specs in POs. At YISHANG, we track roughness (Ra), gloss levels, and finish type.

Compliance Failure

Lack of RoHS/REACH/FDA documentation can cause customs delays or even market rejection.

Mitigation: Partner with manufacturers experienced in cross-border documentation. Don’t rely on verbal assurance.

Choosing Between Grades: Strategic Procurement Guidance

| Grade | Best For | Key Advantage |

| 18/10 | Food, medical, architecture | High polish, excellent weldability |

| 18/8 | General enclosures, indoor frames | Lower cost, decent corrosion |

| 316 | Marine, high-chloride environments | Molybdenum-enhanced corrosion |

| 201 | Low-cost fixtures (non-exposed) | Budget, but prone to rust |

When corrosion control or surface finish consistency are key KPIs, many OEM buyers find 18/10 to be a strategic upgrade worth considering. If your customers are price-sensitive and operating in low-risk environments, 18/8 may suffice.

Avoid side detours like 4140 vs 1018 unless you’re comparing structural carbon steels (not stainless). And for questions like how thick is 18 gauge aluminum, use ≈1.2mm as a rule of thumb in comparative planning.

Why YISHANG Recommends and Supplies Verified 18/10 Stainless Steel

As a factory with 26+ years of experience exporting to 50+ countries, YISHANG has built procurement processes that ensure buyers receive what they ordered—consistently.

We provide:

Batch-level spectrometry reports

Weld process compatibility assessments

Surface finish validation per order

Compliance kits: RoHS, REACH, FDA, ASTM, EN, GB/T

We assist OEM buyers with reliable stainless sourcing every step of the way.

Final Considerations: Making Smart, Scalable Procurement Choices

18/10 stainless steel offers significant advantages—but only if you know how to source, validate, and apply it correctly. For procurement teams managing international fabrication, it minimizes long-term costs through:

Lower defect rates

Stronger client satisfaction

Fewer warranty issues

If you’re scaling production or entering regulated markets, 18/10 stainless steel is a strategic material—not just a spec line. For global procurement teams, understanding the meaning of 18/10 stainless steel, and how it compares with 18/8 and 304, ensures better sourcing decisions and compliance in regulated industries.

Let us help you make the right stainless steel choice—efficiently and confidently.

FAQ: What B2B Buyers Ask Before Sourcing 18/10 Stainless Steel

How can I ensure the material is truly 18/10 when sourcing from overseas?

Request mill test certificates and validate chemical composition, especially nickel content. Third-party spectrometry testing before batch production is highly recommended.

What are the signs that a project requires 18/10 rather than 18/8?

Look for demands involving repeated sterilization, long-term exposure to moisture, or a requirement for uniform finish across large quantities. For example, foodservice teams often ask: what’s the best stainless steel grade for food equipment?—the answer is frequently 18/10.

Among all grades, 18/10 stainless steel is widely recognized as the best stainless steel for food use, balancing corrosion resistance, hygiene, and long-term durability.

Is 18/10 stainless reliable for semi-outdoor or retail infrastructure?

Yes. In environments like malls, transport hubs, and vending enclosures, 18/10 resists corrosion and maintains finish longer than 201 or low-nickel 304.

It’s also dishwasher safe for commercial-grade food-contact surfaces—is 18/10 stainless dishwasher safe? Absolutely, when processed and certified properly.

What processing issues can occur with substandard 304 marketed as 18/10?

You may experience inconsistent surface finish, weld defects, and faster corrosion, especially in humid or hygienic environments.

Is 18/10 stainless steel dishwasher safe?

Yes. Properly certified 18/10 stainless steel is dishwasher safe, retaining shine and resisting pitting even after repeated cycles. This is why it’s the preferred grade for commercial kitchens and catering equipment.

Let us help you choose the right stainless solution for your high-volume production—reach out to YISHANG today.