Introduction

In fast-moving global supply chains, control boxes are critical components that enable industrial automation, safety, and system regulation. For procurement professionals sourcing electrical enclosures in bulk, reliability, certification, and scalability are key.

This article provides a practical, supplier-centric overview of control boxes—from real-world functionality and component structure to design considerations and manufacturing capacity. Built on the experience of YISHANG, a certified OEM control box manufacturer with 26+ years of global export expertise, this guide addresses the purchasing concerns of wholesalers and project managers alike.

How long does powder coating last? With the right materials, curing, and prep—20–30+ years. Without them? Failure in months.

Your customers won’t ask about powder paint chemistry—but they’ll notice if their powder coated surface fades or rusts. Make your sourcing decisions based on performance, not just appearance.

YISHANG helps procurement teams lower long-term cost, improve quality metrics, and protect brand trust through certified, engineered coatings.

What Problems Does a Control Box Solve for Procurement Teams?

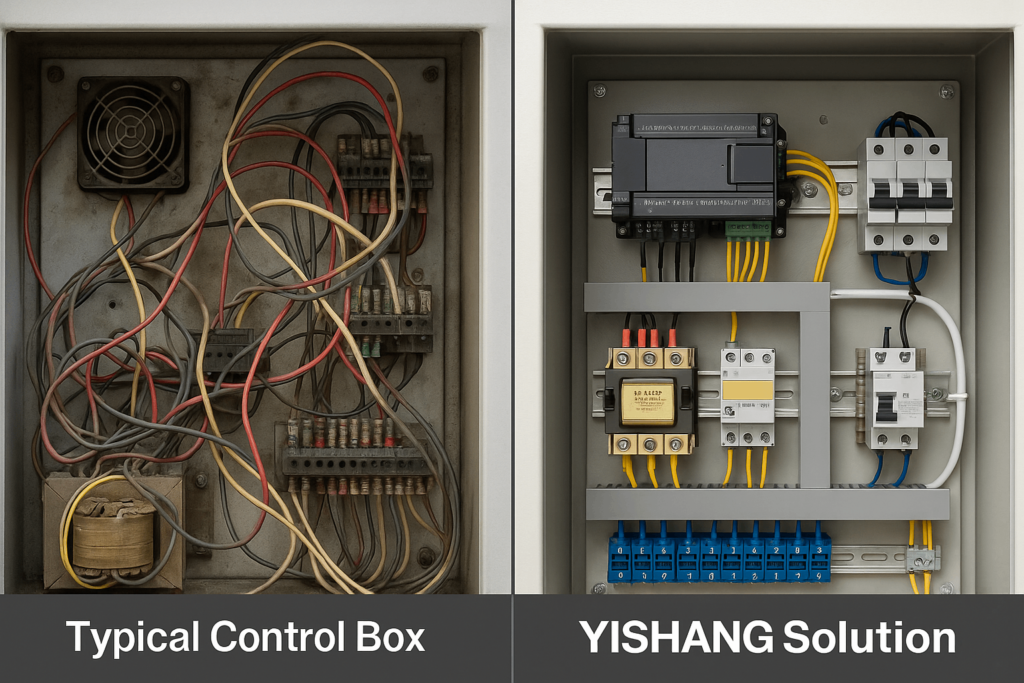

One of the most common issues purchasing managers face is receiving control enclosures that lack IP/NEMA compliance or don’t meet electrical layout standards. These errors cause costly production delays, reworks, and certification failures.

At YISHANG, we solve this early. Our engineers simulate enclosure design using CAD and ensure all outputs comply with UL, CE, and RoHS requirements. This ensures every shipment is installation-ready.

A control box addresses four key system functions:

Power Distribution: Directs and protects electrical circuits with rated isolators, breakers, and connectors.

Control Logic Execution: YISHANG ensures compatibility with PLC brands like Siemens, Omron, and Schneider.

Operator & Network Interface: Supports HMI, SCADA, and Modbus-based feedback loops.

Safety Control: Protects field personnel and equipment with fault isolation and surge suppression.

From production lines to solar fields, control boxes reduce integration risks and operational downtime.

How Control Boxes Operate in Industrial Systems

A control box acts as the central hub where electrical inputs are translated into mechanical or digital actions. For example, in an assembly line, sensor data flows to a PLC. The PLC processes it and triggers outputs—like activating motors or issuing alarms.

YISHANG control boxes are designed to support industrial networking protocols (Modbus RTU, CANopen, Profibus), enabling real-time system monitoring. In one Southeast Asia EV charging deployment, our systems sustained 98% uptime over 12 months under outdoor operation.

Reliable operation is also supported by our fail-safe configurations—breakers, thermal fuses, and grounding protections are integrated to isolate faults without disrupting upstream systems.

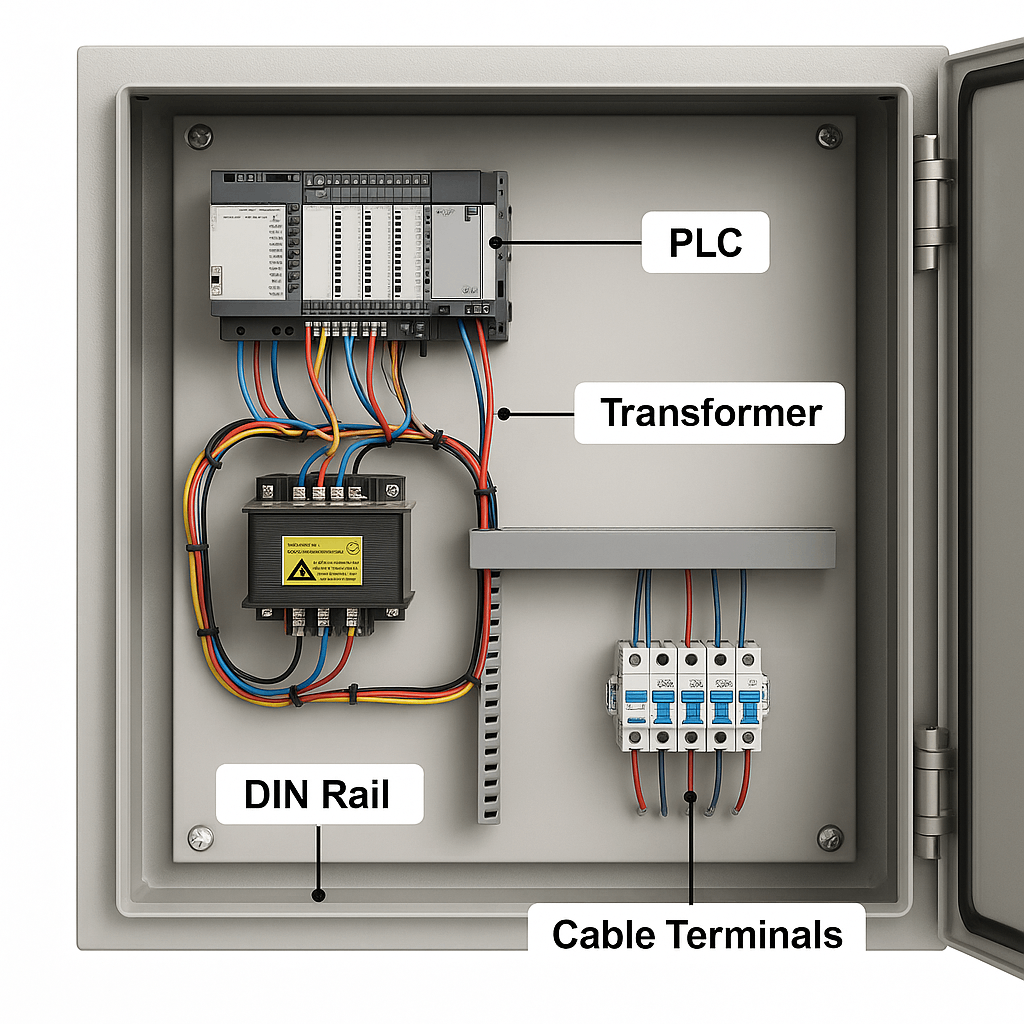

Internal Structure: Core Components With Procurement Relevance

Enclosure: Fabricated using stainless steel 304/316 or powder-coated steel. Salt spray resistance verified up to 720+ hours. IP66/67 protection is standard for outdoor installations.

Power Input & Conversion: AC/DC transformers, terminal blocks, and surge arrestors rated to IEC 60204-1 ensure global voltage compatibility. Our panels are field-tested in solar farms and smart factories.

Control Logic Hardware: PLCs mounted on DIN EN 50022 rails ensure module interchangeability. We preconfigure layouts for Siemens, Delta, and Mitsubishi brands.

Signal I/O Devices: Inputs (pressure, proximity, temperature sensors) and outputs (relays, actuators, alarms) are labeled with laser-marked IDs for easy installation.

Interface Units: HMI panels (IP65+) provide local diagnostics and support RS-485 and Ethernet protocols.

Wiring System: Every terminal and cable route is pre-assembled per your BOM. Modular blocks simplify replacements and reduce technician errors.

Types of Control Boxes Based on Industrial Use Cases

For procurement teams evaluating options, selecting by function is critical:

Industrial Control Box: For conveyors, robotics, and PLC-managed systems.

Electrical Distribution Box: Focuses on routing power, not automation.

Pneumatic & Hydraulic Control Box: Integrated with solenoid valves and fluid sensors.

Automation Cabinet: Includes PLC + I/O + HMI, prewired for machine control.

Form factors:

Wall-Mounted: For compact facilities with limited floor space.

Floor-Standing: For high-power or high-density circuit installations.

YISHANG also customizes for industry-specific needs: vending, energy storage, EV charging, and healthcare. Our retail control boxes integrate coin acceptors, barcode readers, and wireless IoT modules.

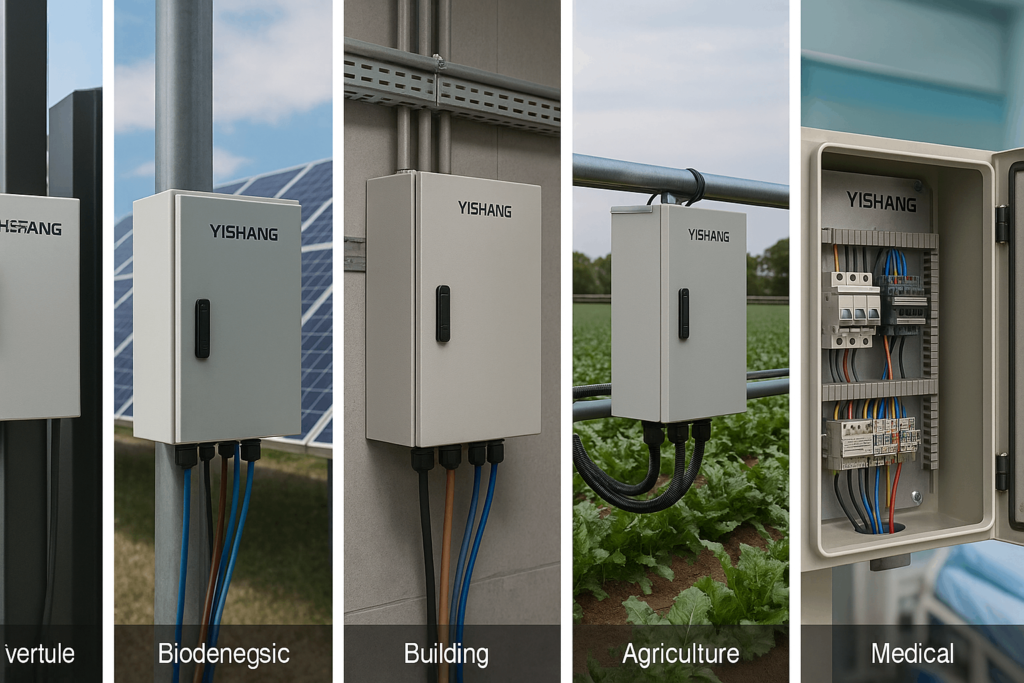

Key Applications That Drive B2B Control Box Procurement

Automotive: Our units are used in 5,000+ robotic welding lines. Each enclosure integrates multiple motor drives and zone isolation switches.

Renewable Energy: We supply IP67-rated boxes for PV systems, integrating battery BMS and grid controllers. All cable entries are sealed to EN 62444.

Building Automation: HVAC, elevator, and lighting panels are supplied prewired and terminal-labeled for plug-and-play integration with BMS systems.

Agriculture: Smart irrigation control enclosures support pH, temperature, and flow sensors. Used in precision farms across Europe.

Medical Devices: Class II-compliant enclosures for sterilizers and analyzers. YISHANG offers RoHS-compliant powder coating for cleanroom compatibility.

Designing for Export: What Procurement Managers Should Prioritize

Material Matching: Use 316 stainless for coastal installations; aluminum or PC-ABS for indoor systems. Our team advises based on local climate specs.

Ventilation Strategy: Natural convection for <100W, forced fans above 300W. We simulate heat maps in SolidWorks.

Standard Compliance:

UL 508A and IEC 60204-1 for electrical control panels

RoHS and REACH for European market access

CE/CB for international approvals

Prewired Flexibility: We pre-design for additional relay slots or Ethernet ports, allowing future expansion.

Labeling & Testing: Laser-etched IDs and color-coded wires reduce field confusion. Each unit is function-tested before shipping.

| Component | Standard | Benefit |

|---|---|---|

| Cable Gland | IP68 / EN 62444 | Sealed, strain-resistant |

| Enclosure Finish | ISO 12944-6 | Corrosion protection |

| PLC Slots | IEC 61131-2 | Brand interchangeability |

Common Design Oversights—and How We Prevent Them

Case Study: Southeast Asian Packaging Line

The plant reported frequent thermal trips. Upon review, their boxes lacked ventilation and had undersized breakers. YISHANG redesigned enclosures with rated ventilation and component spacing. Downtime dropped by 23% in two weeks.

We prevent similar errors with:

Load de-rating per IEC standards

Ventilation placement simulation

Real-time thermal test before delivery

Our standard QC includes:

Visual inspection

Insulation resistance test

Functional circuit verification

Standard vs. Custom: Choosing Based on Volume and Complexity

Standard Boxes suit:

Short timelines

Budget-sensitive projects

Basic distribution needs

Custom Boxes are ideal for:

OEM/ODM branding

Multi-function enclosures

Export compliance

YISHANG supports bulk customization: branding, language labels, modular layouts. All designs verified in CAD prior to production.

Lead Time:

Samples: 7–10 working days

Batches under 1,000 units: 15–20 working days

YISHANG Fabrication Capacity & Process Overview

As a full-service OEM, YISHANG manufactures in-house:

Laser Cutting: Up to 3mm stainless, 6mm aluminum

CNC Bending: ±0.2mm repeatability

Welding: Spot, TIG, or MIG options

Powder Coating: RoHS-compliant, 500+ hour salt spray tested

Assembly: Includes terminals, wire routing, component fitment

QC across four stages:

Raw material

Pre-coating

Post-assembly

Final inspection

We support MOQ 50 units and monthly volumes up to 10,000 pieces.

Final Thoughts

A reliable control box supplier is essential for minimizing procurement risk and ensuring regulatory-ready shipments. YISHANG delivers not only compliance and quality—but also scale, technical guidance, and competitive turnaround.

📩 Reach out to discuss your custom control box requirements.