In global manufacturing, tools that ensure repeatability and accuracy are invaluable. Among these, the jig remains one of the most practical yet powerful solutions—especially for bulk production. While machines and automation systems often attract the spotlight, the reliability and scalability enabled by a well-designed jig are what many procurement professionals ultimately rely on.

This article presents a comprehensive guide to jigs—from what they are and how they work to why they matter for overseas buyers managing complex supply chains. Whether you’re sourcing from Asia or looking to streamline production workflows, understanding the strategic value of jigs is essential.

Foundations — What Is a Jig and Why It’s Indispensable

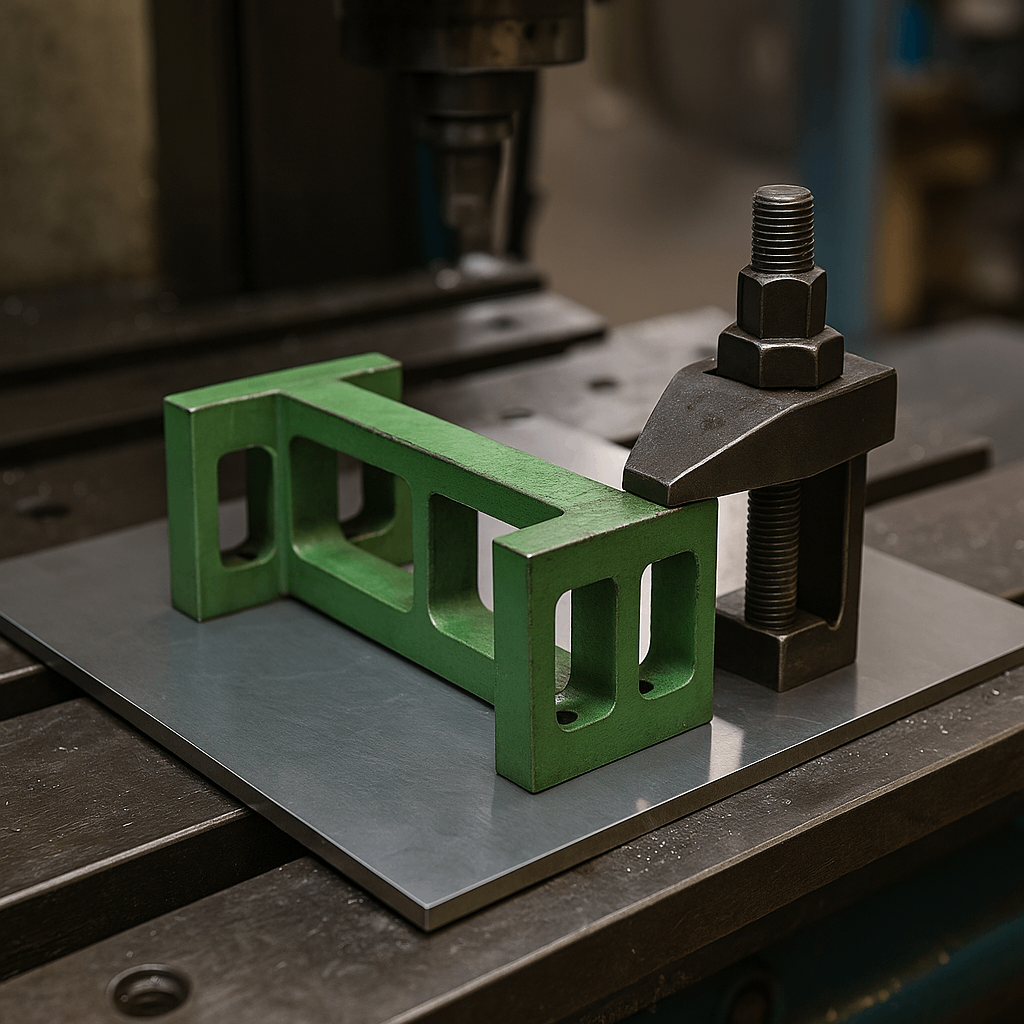

A jig is a type of custom manufacturing tool designed to guide the cutting or positioning of components with precision. In practice, it ensures both the accurate placement of the part and the controlled path of the tool performing the operation. This distinguishes jigs from fixtures, which only hold the workpiece without directing tool movement.

The core purpose of a jig is to minimize variation during repetitive tasks. That’s why high-volume manufacturers across sectors use jigs to maintain consistent quality, even in environments with less-skilled operators. This consistency supports scaled production while safeguarding dimensional tolerances.

Today’s jigs integrate advanced materials and technologies—from aluminum and hardened steel to CNC compatibility and sensor-enabled designs. In fields such as aerospace or battery production, tolerances under ±0.05 mm are expected. Without a jig to enforce this precision, risk to part integrity and compliance increases.

Why Jigs Matter — Strategic Benefits in Manufacturing

For procurement teams sourcing millions of components annually, cost and consistency drive decisions. Jigs support both. By ensuring each workpiece is positioned accurately, they help avoid costly rework, reduce waste, and increase cycle efficiency.

In practical terms, a jig supports quality programs like ISO 9001 and Six Sigma. It helps maintain tolerance stacks, improve first-pass yield, and eliminate human deviation. For clients requiring RoHS-compliant production, jigs also minimize contamination risk in electronic or medical-grade environments.

From an operational standpoint, jigs simplify training and reduce onboarding time. Operators don’t need expert-level machining skills to achieve consistent output. This scalability in labor makes jigs a long-term asset, especially when managing outsourced production.

Types of Jigs — Function-Based Classification

Different operations demand different jig types. Here are five functional categories relevant to most manufacturing lines:

Drill Jigs: Used in automotive and aerospace applications, drill jigs position and guide drills for accurate hole placement. They eliminate the need for manual layout, reducing time and increasing accuracy.

Welding Jigs: Common in chassis and structural fabrication, welding jigs hold parts in alignment and resist heat distortion. Their rigidity ensures precision over long runs.

Assembly Jigs: Designed for component mating or multi-part builds, these jigs help streamline repetitive assembly. Multi-axis clamps and ergonomic design are typical.

Inspection Jigs: For quality control tasks, inspection jigs provide consistent part orientation and can be paired with dial gauges or digital sensors.

CNC Workholding Jigs: Precision is everything in CNC machining. These jigs prevent vibration, ensure flatness, and accommodate vacuum or magnetic clamping systems.

Each type plays a crucial role in enhancing throughput and eliminating uncertainty—two priorities procurement professionals track closely.

Industry Applications — Solving Real Procurement Challenges

Automotive: Large-scale car manufacturers require interchangeable parts with tight tolerances. Jigs are central to welding and assembly lines, especially where daily changeovers occur. Procurement managers benefit from reduced downtime and improved takt time.

Medical Devices: Here, the stakes are regulatory. Jigs made from FDA-compliant materials like PEEK or stainless steel help stabilize ultra-small components. Their use reduces the number of touchpoints and supports cleanroom processing.

Sheet Metal Fabrication: Warping, slippage, and burn marks are common risks. Jigs with non-marring clamps ensure part stability during cutting, punching, and bending. For B2B buyers, that means fewer rejected parts and lower total cost of ownership.

Energy Systems: In battery or storage modules, jigs facilitate thermal gap consistency and prevent short circuits. Use of insulating composites ensures both safety and compliance in assembly. This supports growing procurement demand in the EV sector.

Aerospace: Aerospace buyers demand traceable tooling. Jigs in this space often include RFID tags and digital logs. Their lightweight yet rigid construction ensures parts meet aerospace-grade quality without compromising speed.

Jig Design — From CAD Model to Production Line

Good jig design starts with the application. What’s the material? What are the repeatability requirements? What tooling will interact with the jig? Procurement teams should prioritize partners who offer DFM (design for manufacturability) reviews early.

Modern jig development begins in CAD platforms such as SolidWorks or Fusion 360. Engineers simulate mechanical loads, test virtual clamps, and run ergonomic checks. Prototypes are often CNC-machined or 3D-printed for quick evaluation.

Custom jigs are best for high-volume production. Modular jigs work well in development lines. But either way, smart design reduces changeover time, improves uptime, and prevents injuries. Standards such as ISO 12100 and ANSI B11.19 guide safe and efficient jig ergonomics.

At YISHANG, we often embed quick-release clamps, anti-fatigue handles, and dust shields. These features aren’t “nice-to-haves” for the buyer—they reduce training time, service intervals, and replacement costs.

Operational Integration — How YISHANG Uses Jigs to Deliver Efficiency

YISHANG’s jig systems are built around reliability and precision. In our sheet metal division, custom locator pins and magnetic clamps reduce laser cut misalignment by over 15%. This directly improves delivery consistency for our wholesale clients.

During CNC milling, workholding jigs absorb vibration through internal damping inserts, extending tool life by up to 20%. For clients placing bulk recurring orders, this reduces indirect costs significantly.

Every jig is logged and inspected every 5,000 cycles. Our quality team uses calibrated sensors to detect wear. Drift beyond 0.02 mm triggers preventive maintenance. This ensures consistent output across long-term purchase contracts.

We follow Six Sigma principles and provide documentation upon request. This aligns with enterprise-grade procurement audits, especially from automotive and electronics buyers.

Choosing the Right Jig — A Buyer’s Guide

When selecting a jig, consider your product’s complexity and production volume. For short runs or R&D, modular jigs provide flexibility. For ongoing series production, a custom jig built to your part’s geometry will pay off in time and cost savings.

Key purchase factors include:

Repeatability: Does the jig produce consistent results across thousands of parts?

Setup Time: How fast can it be locked/unlocked for changeovers?

Compatibility: Can it be used with your existing CNCs, presses, or welding robots?

Maintenance: Are materials corrosion-resistant? Are replacement parts standardized?

Avoid overcomplicated designs. A good jig must be easy to operate, easy to clean, and built to last. Talk to suppliers who offer sample trials and DFM feedback.

Jigs in the Smart Factory — Digital, Data-Driven, and Sustainable

Industry 4.0 is changing how we build jigs. Smart jigs at YISHANG now include pressure sensors, RFID tracking, and usage counters. Operators are alerted when misalignment exceeds limits—before any defect occurs.

Digital twins allow us to simulate clamp forces, cycle time, and load distribution. This helps overseas buyers evaluate feasibility before tooling investment. For example, one of our clients reduced tooling revisions by 25% through virtual validation.

Eco-friendly jig designs are also gaining traction. Buyers increasingly request recyclable aluminum bodies or FSC-certified wooden handles. By optimizing materials and reducing tooling waste, we support ESG procurement standards.

Conclusion

Jigs are not just engineering accessories—they are procurement assets. In the hands of a capable manufacturer like YISHANG, they translate to better quality, faster delivery, and lower total cost for clients.

Understanding what is a jig, and selecting the right partner to design and produce it, can have measurable impact on your product success and supply chain resilience. Especially in a global context, precision tooling like jigs becomes a competitive differentiator.