For businesses involved in large-scale procurement of precision components, understanding machine tools like lathes is crucial. Lathe machines are essential for shaping materials with rotational symmetry, such as shafts and gears. Whether your company needs high-precision custom-machined parts or a supplier capable of meeting bulk procurement deadlines, partnering with a reliable machining service provider ensures efficient manufacturing and superior quality. This article explores the different types of lathes, their operations, and how outsourcing machining services can help businesses optimize production and meet their goals.

What is a Lathe Machine?

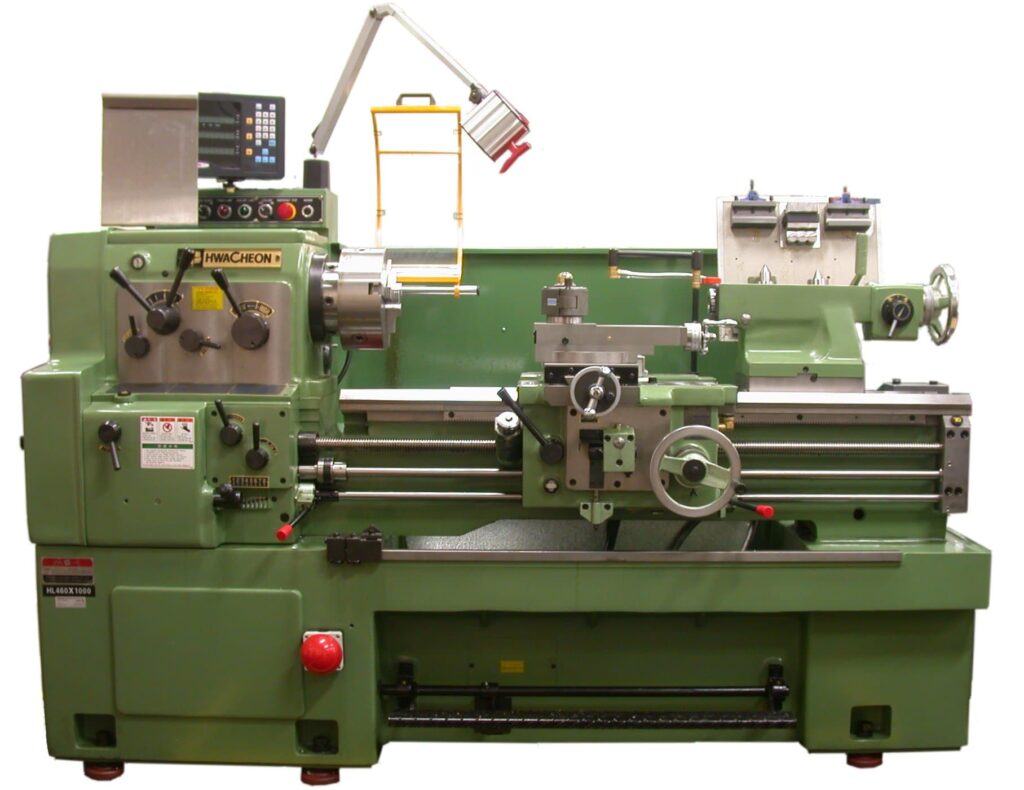

A lathe machine is a versatile machine tool that rotates a workpiece while a cutting tool removes material to shape the object. This process is essential for creating parts like shafts, rods, and other cylindrical components. Lathe machines are employed across various industries, including automotive, aerospace, and medical device manufacturing, where high precision is required.

Basic Working Principle

The principle behind a lathe machine involves rotating the workpiece while the cutting tool shapes it into the desired form. This allows for operations like turning, threading, and boring. CNC (Computer Numerical Control) technology enhances the operation by automating tool movements, which increases production speeds and accuracy.

In CNC-controlled lathes, both the cutting tool and workpiece are controlled by a computer, which reduces human error and ensures consistent results. This is especially important in high-volume production, where precise and repeatable results are crucial.

Key Components of a Lathe Machine

Understanding the components of a lathe is essential for understanding how it performs various machining operations. The primary components include:

| Component | Description |

|---|---|

| Bed | Provides the foundation of the lathe, supporting all components and absorbing vibrations. |

| Headstock | Houses the motor and spindle, responsible for rotating the workpiece. |

| Tailstock | Supports the opposite end of the workpiece, preventing wobbling and ensuring stability. |

| Carriage | Holds and moves the cutting tool along the length of the workpiece. |

| Tool Post | Secures the cutting tool and allows for adjustments during machining. |

These components work in harmony to ensure smooth operation and high precision during machining.

Lathe Operations: Key Processes for High-Precision Parts

Lathe machines are capable of performing a variety of operations, each designed to meet specific manufacturing needs. Understanding these operations can help wholesale buyers and manufacturers select the right machining services provider.

Turning: The most common operation, where the workpiece is rotated while the cutting tool shapes it into a cylindrical form. This process is used to make parts like shafts and rods, common in machinery and automotive applications.

Threading: Lathe machines can cut internal or external threads on a part. This is critical for producing fasteners such as screws, bolts, and nuts, which are necessary for mechanical assemblies.

Boring: Boring enlarges an existing hole in a part with high precision. It is essential when parts require accurately sized and smooth holes.

Drilling: Lathe machines can also perform drilling operations, creating holes for fasteners or material connections.

Facing: Facing involves cutting the end of a workpiece to create a flat, smooth surface, which is often required for further machining or assembly.

Each of these operations plays a crucial role in ensuring that parts are produced with the highest levels of precision and consistency.

Choosing the Right Machine Tool: Types of Lathes

Selecting the appropriate machine tool for your needs is critical for ensuring that parts meet your manufacturing requirements. Different types of lathes are designed for specific tasks, depending on the material, complexity, and precision required.

Common Types of Lathe Machines

| Type of Lathe | Description |

|---|---|

| Engine Lathe | A general-purpose machine tool ideal for turning, facing, and threading. |

| CNC Lathe | A computer-controlled lathe, perfect for high-precision, large-scale production. |

| Turret Lathe | Features a rotating turret with multiple tools, ideal for high-volume production. |

| Bench Lathe | A smaller, benchtop lathe used for light-duty tasks requiring high precision. |

| Special Purpose Lathe | Designed for specific tasks such as pipe threading or specialized production. |

Why CNC Lathes are Ideal for High-Volume, High-Precision Production

For wholesale buyers who need large quantities of identical parts, CNC lathes are often the best option. These machines offer several key advantages:

Increased Precision: CNC machines produce parts with minimal variation, maintaining consistent quality throughout production.

Efficiency: Automation speeds up production and reduces the need for manual labor, resulting in lower operational costs.

Complexity: CNC lathe machines can handle intricate designs that may be difficult or impossible to achieve with traditional manual machines.

As CNC machining becomes more widely adopted, it is expected to continue to grow. The global CNC machining market is projected to reach $72 billion by 2030, expanding at a CAGR of 7.3% from 2022 to 2030, according to Grand View Research.

Lathe Safety: Ensuring Safe and Efficient Machining

When working with lathe machines, safety is paramount. Adhering to strict safety guidelines minimizes the risk of accidents and ensures smooth operation.

Lathe Safety Best Practices:

Wear Protective Gear: Always wear safety goggles, gloves, and hearing protection to protect against debris and loud noise.

Check Safety Shields and Guards: Make sure that all safety shields and guards are securely in place before starting the machine.

Keep Tools Sharp: Dull tools can cause accidents and reduce the quality of machining. Regular maintenance and sharp tools are essential.

Power Off for Adjustments: Always power off the machine before making any adjustments to the workpiece or cutting tool to avoid accidents.

Partnering with Professional Machining Service Providers

Partnering with a reliable machining service provider ensures that safety protocols are followed, reducing the risk of injury and ensuring the quality of produced parts.

Lathe Machining Services: Enhancing Manufacturing and Bulk Procurement

Outsourcing lathe machining services offers numerous advantages, including cost savings, scalability, and the ability to meet wholesale procurement needs. These services provide critical support for businesses looking to enhance their manufacturing processes.

Why Lathe Machining Services Matter for Wholesale Buyers:

Customization: Lathe machining services provide tailored solutions to meet specific material, size, and design requirements.

Global Logistics: Reliable service providers ensure on-time deliveries, reducing delays and supply chain bottlenecks.

Quality Assurance: These services adhere to international quality standards, including ISO 9001 and RoHS compliance, ensuring that parts meet the highest specifications.

Key Benefits of Lathe Machining Services:

Cost-Effectiveness: Outsourcing machining services eliminates the need for costly investments in machinery, reducing overhead costs for businesses.

Scalability: Lathe machining services can scale to meet both small and large production runs, making them ideal for bulk procurement.

Expertise: Experienced machinists ensure that parts are manufactured to exact specifications, delivering consistent results.

Lathe machines are indispensable tools in precision manufacturing, offering flexibility, accuracy, and efficiency. By understanding the functions of these machines and partnering with a trusted machining service provider, wholesale buyers can streamline their procurement processes and ensure the timely delivery of high-quality components. Whether you require customized parts or high-volume production runs, lathe machining services provide the precision and efficiency needed to meet your manufacturing goals.

Are you ready to optimize your production with high-quality lathe machining services? Contact YISHANG today to discuss how our can help you achieve precision, efficiency, and cost-effective solutions for your bulk procurement needs.