Introduction

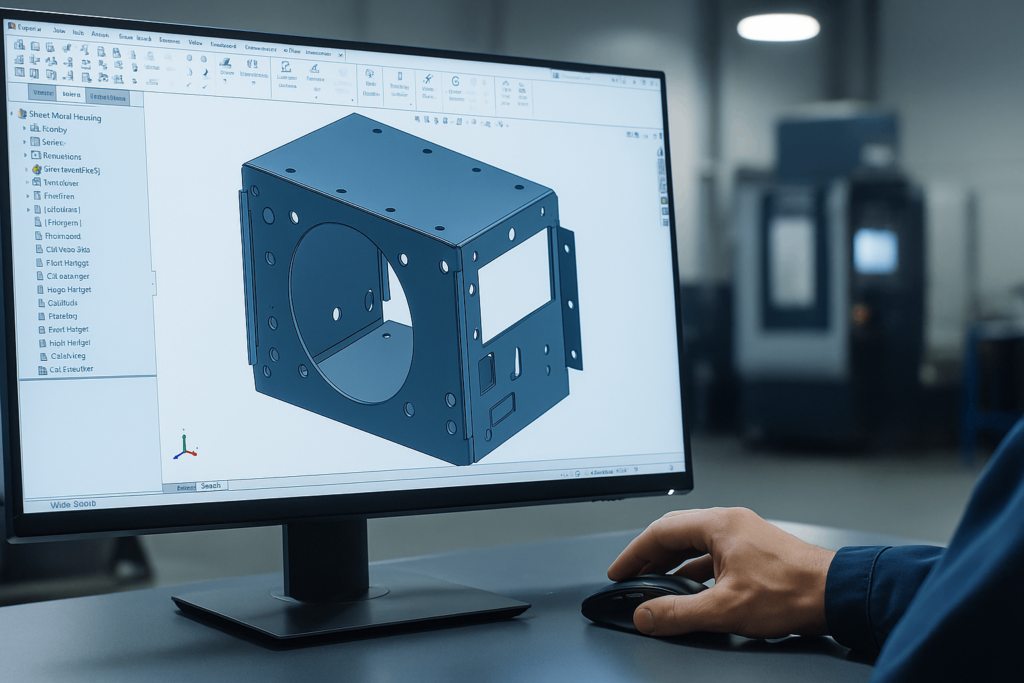

For industrial buyers, accurate drawings and efficient design communication are key to seamless manufacturing. This is where Computer-Aided Design (CAD) becomes a vital component in global sourcing and production.

This guide focuses on CAD tools and modeling technologies, their role in industrial manufacturing, and how understanding technical drawing capabilities can help procurement professionals source smarter, reduce production risks, and ensure design-to-delivery consistency.

Whether you’re reviewing STEP files from your engineering team or looking to validate a supplier’s infrastructure, knowledge of design platforms gives you leverage. The right questions at the RFQ stage can save thousands in misalignment, scrap, or lead time.

Understanding CAD – From Technical Drawing to Strategic Sourcing

So, what exactly is CAD? In the most functional sense, CAD software is used to create digital models—2D or 3D—of components or products. These models are rich in data: dimensions, tolerances, materials, and even simulated stress results.

A technical drawing, then, is more than a sketch. It’s a controlled, shareable, and editable document that speaks directly to machines—via formats like DXF, IGES, or STEP. For buyers, the value is clear: reduce interpretation errors and ensure exact replication across batches.

Modern engineering tools also integrate with manufacturing software, allowing the same file to instruct CNC machines, laser cutters, or press brakes. This synergy is central to manufacturing consistency. When you partner with a vendor like YISHANG who supports CAD-CAM alignment, you’re securing repeatability.

From a procurement perspective, these systems bring benefits such as reduced quoting time, faster DFM feedback, and the ability to request small adjustments without full redesigns. These advantages of CAD translate directly to smoother procurement cycles and higher fulfillment confidence.

Types of CAD Tools – What Procurement Needs to Clarify

Which design systems are used, and how do they impact your sourcing strategy? While engineers distinguish between parametric and direct modeling, buyers should focus on what formats suppliers support and how designs translate to production.

2D design software—used in simpler components or flat profiles—still matters for stamping, bracket layouts, and laser-cut plates. But its limitations become obvious in assemblies. For custom enclosures, bent panels, or load-bearing structures, 3D modeling becomes essential.

Popular platforms like SolidWorks or Fusion 360 allow vendors to simulate stress, motion, and compatibility. Buyers should confirm that their suppliers are using up-to-date drafting programs with features like unfolding for sheet metal. This is critical to reduce distortion risk and speed up fabrication.

Also consider if suppliers use industry-specific solutions, such as those supporting piping or electrical layouts. Even in sheet metal, having access to smart modules that support nesting for material optimization is a direct cost-saving factor.

Ask vendors directly: Do you run design feasibility checks? Do you accept STEP files without conversion? These aren’t just IT questions—they affect your lead time and consistency.

CAD in Manufacturing – A Buyer’s Workflow Perspective

From RFQ to mass production, design files shape each step of the workflow. Understanding how your supplier uses these tools ensures that design integrity is preserved throughout the process.

When YISHANG receives your 3D models or technical drawings, we validate them using internal design rules. Features like hole-to-edge distances or bend radii are checked against our capabilities. This step—often overlooked by less mature factories—prevents last-minute redesigns and costly fabrication errors.

In advanced workflows, digital models integrate with CAM systems, allowing tool paths to be generated automatically. This eliminates manual data reentry, one of the biggest causes of errors in overseas manufacturing. It also ensures your part gets made exactly as intended.

CAD-CAM integration is also vital for prototyping and low-volume runs. Because everything is digital, changes can be implemented quickly, quotes are generated faster, and no information is lost between engineering and machining.

Evaluating Vendor Readiness – Sourcing Questions That Matter

From a procurement standpoint, one of the most underestimated advantages of CAD is vendor transparency. A supplier who accepts your 3D files, maintains revision control, and outputs CAM-ready drawings is operationally ahead.

When qualifying vendors, ask:

What CAD software do you use, and is it compatible with ours?

Do you provide design-for-manufacturing (DFM) suggestions?

Can you run simulations or digital assembly previews?

Do you store and version-control our project files securely?

A supplier who says “Send us your PDF” versus one who says “Upload your STEP and we’ll validate bend allowances and nesting layouts” shows two different maturity levels.

The advantages of CAD/CAM integration are not only in production—but also in how a vendor collaborates with your engineering team. Clarifying these details early reduces downstream RFQs, quality disputes, and material waste.

Strategic Value – Why Procurement Should Care

Let’s move from technicalities to strategy. The benefits of CAD can help buyers:

Cut quoting time by 30–50% through clean file exchange

Reduce non-conformance issues caused by translation errors

Speed up change management during prototyping or ECO cycles

Buyers can also evaluate multiple vendors more efficiently. Those who support CAD standards tend to offer more accurate lead time estimates and more realistic tolerances. This matters especially in high-mix, low-volume (HMLV) runs common in global sourcing.

The main challenge? Onboarding. But this is your supplier’s job. You just need to ensure they have the setup and skills to read, process, and execute based on your CAD files.

Technology Trends – What Global Buyers Should Watch

The CAD industry isn’t standing still. Emerging tools make sourcing even more efficient for buyers who are CAD-aware.

Cloud-based design platforms now support real-time collaboration between design teams in Europe and fabrication partners in Asia. Software like Onshape or Fusion 360 allows file access, annotation, and live editing. For buyers, this means fewer misunderstandings and faster design confirmation cycles.

AI is also entering the picture. Smart drafting tools now flag potential interference or manufacturability issues before files are even exported. This predictive capacity is invaluable when you’re balancing cost, time, and feasibility.

Another area: Generative design. While not every buyer uses it, knowing that your supplier can work with optimized, software-generated models means you’re open to more cost-effective and performance-optimized parts.

Understanding CAD/CAM innovations helps you select a vendor that’s ready for the next era of digital manufacturing.

Conclusion

CAD is no longer a niche engineering term. For procurement professionals, understanding what is CAD translates directly to more accurate quotes, shorter timelines, and fewer production errors.

A supplier’s CAD capabilities are a strong predictor of how reliable they’ll be when deadlines are tight and tolerances are critical. YISHANG has invested in both tools and expertise to serve this exact need.

FAQ

Q1: What is CAD used for in industrial manufacturing?

CAD helps manufacturers create precise technical drawings and 3D models. These files are used for design validation, quoting, tooling, and even directly driving CNC machinery.

Q2: What file formats should I send to suppliers like YISHANG?

Preferred formats include STEP (.step, .stp), DXF, and IGES. These are widely supported by CAD/CAM systems and help reduce translation errors.

Q3: Is CAD relevant even if I only order stamped or bent sheet metal parts?

Yes. Even flat profiles require accurate 2D CAD files for laser cutting or stamping. If bending is involved, 3D models help avoid tolerance errors.

Q4: Can I request design changes or DFM support from my supplier?

Definitely. Suppliers like YISHANG offer DFM suggestions based on your CAD files to improve manufacturability, reduce cost, and avoid defects.

Q5: What are the advantages of CAD for global sourcing?

CAD ensures consistency across borders. With the same design file, you can source from multiple vendors and still maintain accuracy, save time, and reduce the risk of miscommunication.