What is Forming?

Forming is a metalworking process that reshapes metal using mechanical force without removing or adding material. It plays a vital role in manufacturing by enabling efficient, scalable, and waste-minimizing production. Common forming methods include bending, rolling, stamping, and deep drawing.

For international buyers, particularly OEM/ODM procurement specialists, understanding metal forming is critical to sourcing cost-effective, scalable, and specification-aligned components. Unlike general machining, forming enables mass production with higher material efficiency and faster throughput.

In this guide, YISHANG shares key insights drawn from 26+ years of experience in sheet metal processing. We’ll walk through the main forming types, decision-making factors, technical standards, and real-world procurement applications to help you choose the right supplier and process for your needs.

Understanding Metal Forming in the Procurement Context

Metal forming is the mechanical reshaping of metal—typically steel, aluminum, brass, or copper—achieved through plastic deformation. This means that the material is compressed, bent, or stretched beyond its elastic limit, permanently changing shape without cracking or breaking. For instance, bending forming is widely used to fabricate enclosures, brackets, and frames without seams or welds.

From a sourcing perspective, forming is favored because it minimizes material waste, enables high-throughput production, and maintains dimensional consistency across batches. It also plays a vital role in precision sheet metal forming, where achieving consistent tolerances and surface finishes is essential for quality assurance.

At YISHANG, forming is fully integrated with laser cutting, CNC machining, press brake forming, welding, surface treatment, inspection, and final packaging. This end-to-end production control is critical for overseas buyers looking for speed, reliability, and cost transparency.

Forming in Modern Manufacturing

Metal forming is a core pillar of modern manufacturing workflows. Unlike subtractive processes like CNC machining, forming transforms material using force, making it highly efficient for high-volume production.

Manufacturers rely on forming for:

Lower material waste

Higher part consistency

Reduced post-processing

Seamless integration with welding, coating, and assembly

This is especially true in OEM metal manufacturing, where tight timelines and cost control demand reliable forming processes such as stamping and bending.

Classifying Metal Forming Processes

Understanding how metal forming is categorized helps buyers align part designs with appropriate processes and capabilities. Two primary classification methods are based on deformation mode and processing temperature.

By Deformation Mode

Forming is either classified as bulk forming or sheet metal forming. Bulk forming processes such as rolling, forging, and extrusion are applied to thick or massive metal forms and are typically used for making shafts, beams, or structural bars. On the other hand, sheet forming techniques—such as bending, stamping, and deep drawing—are optimized for flat metal sheets that require shape changes without significantly altering thickness. These are ideal for enclosures, display panels, and structural housings.

When parts demand high surface integrity and tight tolerances, as in precision sheet metal forming, sheet-based processes are often preferred for both function and cost-efficiency.

By Processing Temperature

Metal forming also differs based on the temperature at which the material is processed. In cold forming, deformation occurs at room temperature, producing higher strength due to strain hardening. It is ideal for high-volume parts where dimensional control and surface finish are critical.

Hot forming takes place above the material’s recrystallization point, allowing greater flexibility and reduced forming force. This is useful for parts with complex geometry or thicker cross-sections. Warm forming operates between the two extremes, balancing material ductility with tool life and energy consumption.

For buyers, understanding the temperature window is key to anticipating tooling cost, material selection, and post-processing requirements, all of which impact overall procurement economics.

Key Types of Metal Forming Processes

Bulk Metal Forming Processes

Rolling reshapes large volumes of metal by passing them between rollers, commonly used to produce sheet, bar, and structural profiles. Cold rolling achieves better precision and surface finish, while hot rolling is faster and more energy-efficient.

Forging uses compressive force to deform metal between dies, often yielding parts with superior grain alignment and mechanical strength. This is ideal for automotive, aerospace, or machinery components subjected to high loads.

Extrusion pushes metal through a die to form parts with uniform cross-sections, such as tubes, rails, or heat sinks. It’s commonly applied to aluminum or forming steel sheet, with high efficiency and material utilization.

Wire drawing reduces the diameter of a metal rod by pulling it through a series of dies. It is widely used in producing cables, springs, and electronic connectors, where fine tolerance and tensile strength are critical.

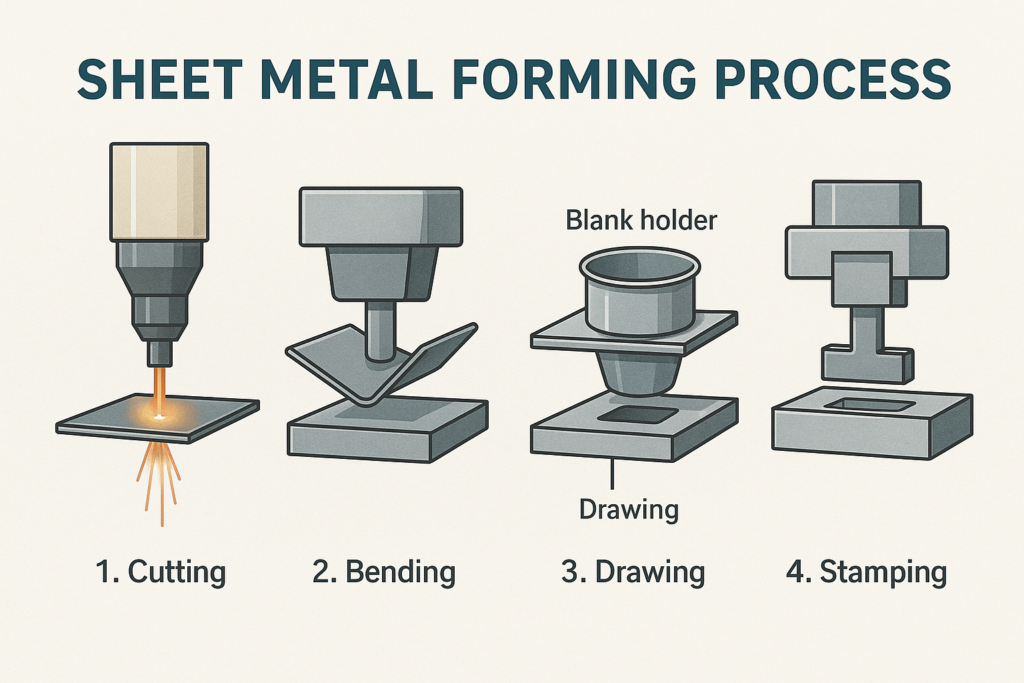

Sheet Metal Forming Processes

Bending involves reshaping flat sheets by applying force along a single axis. Press brake forming is a CNC-controlled method that ensures repeatable, accurate bends, widely used for brackets, chassis, and frames.

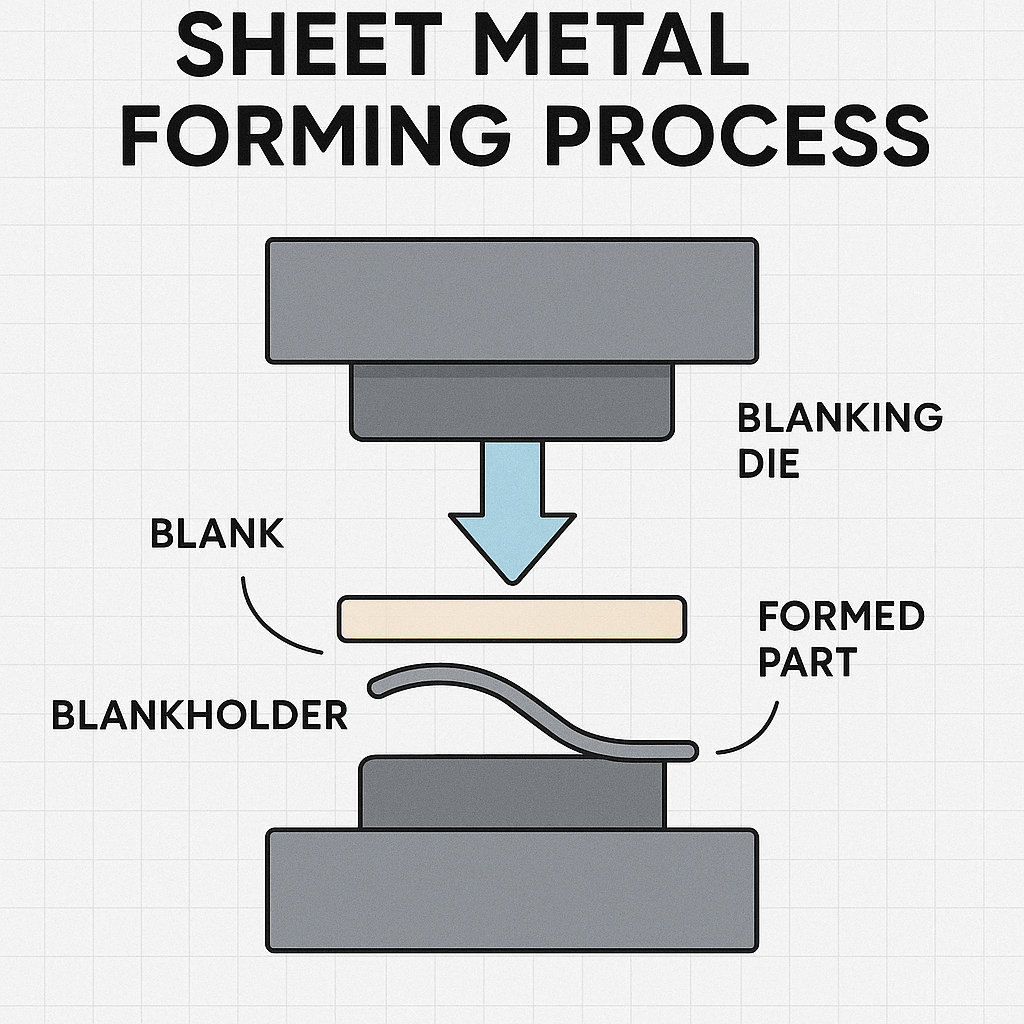

Deep drawing transforms flat sheet blanks into cylindrical or box-like shapes by drawing the material into a die using a punch. It enables the production of seamless enclosures, reducing welding steps. For example, a client from Germany sourced stainless steel deep drawn enclosures for EV charging stations, requiring precise draw ratio control to prevent tearing and ensure dimensional stability.

Stamping is a high-speed process that includes blanking, flanging, and embossing, performed with progressive dies. It’s cost-effective for medium to high-volume production of simple to moderately complex parts.

Hydroforming uses hydraulic pressure to shape ductile metals into complex, lightweight parts without seams or welds. This method is often applied to automotive frames, exhausts, and medical carts, where performance and form are both priorities.

Simulation and Prototyping in Forming Projects

For overseas buyers and technical sourcing specialists, simulation and prototyping are crucial in reducing uncertainty and ensuring accurate outcomes before committing to bulk production.

Finite Element Analysis (FEA) in Practice

At YISHANG, we implement FEA (Finite Element Analysis) software such as AutoForm and Pam-Stamp to simulate forming operations before tooling is fabricated. This step is essential for identifying critical risks including:

Material thinning in complex geometries

Wrinkling or tearing in deep drawing zones

Springback in bending forming processes

Die interference or clearance mismatches

These simulations ensure formability and reduce the need for costly iterations. For components made using forming steel sheet into precise geometries, such virtual validation prevents trial-and-error on production equipment.

Our simulation workflows follow ISO 20482:2013, which standardizes sheet metal formability evaluation.

Prototyping and Validation

After simulation, we manufacture soft tooling or CNC-machined samples for prototyping. This step allows procurement teams to validate part geometry, edge integrity, and post-forming dimensions under actual production-like conditions.

In one North American project, a client sourcing deep drawn powder-coated kiosks required tight flatness (<0.2mm). Our prototyping helped fine-tune corner radii, saving over 15% in post-processing and ensuring final fit with electronic modules.

We advise all new partners to approve pilot runs—especially when transitioning from machined to formed parts. This ensures quicker design sign-off, risk reduction, and smoother production scaling.

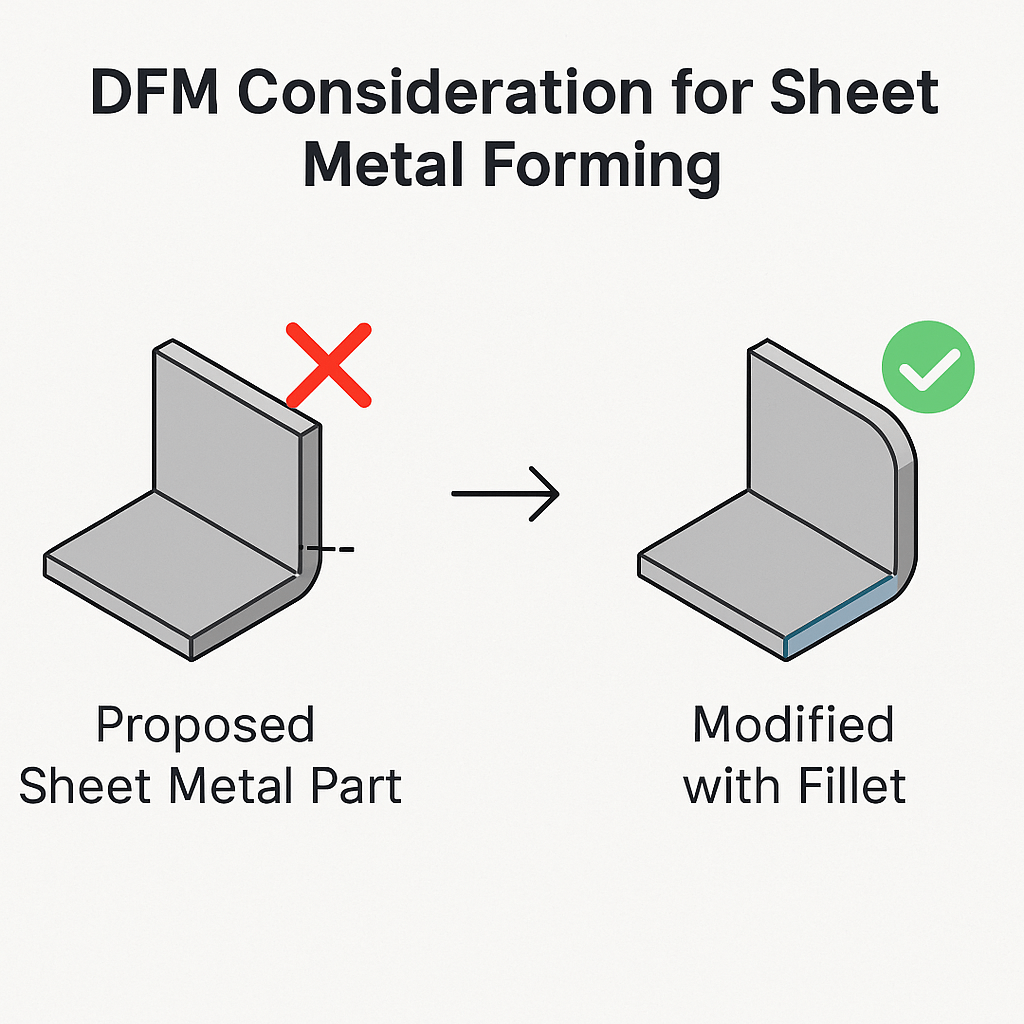

Design for Manufacturability (DFM): Reducing Cost Through Smarter Design

Early DFM feedback can significantly impact downstream efficiency. Our engineering team collaborates directly with clients during the quotation phase to evaluate whether designs are feasible, cost-effective, and scalable.

Key DFM Recommendations from YISHANG

Bend radii should be ≥1x material thickness to prevent cracking.

Hole-to-bend distances must be sufficient to avoid deformation (typically >2x thickness).

Uniform wall thickness ensures even flow, critical for deep drawn parts.

Tolerances must match forming capabilities—avoid applying CNC-level precision to stamping parts.

Grain direction affects bending cracks and should be addressed early.

We also input real-world forming feedback into CAD models, adjusting dimensions based on material springback or tool relief. These insights can reduce tool wear, improve first-pass yield, and lower overall lead time.

Choosing the Right Forming Process for Your Part

Selecting a forming process isn’t just a technical decision—it directly affects tooling investment, lead time, and quality stability.

Our engineering + sales teams at YISHANG help procurement specialists match part requirements with process capability by analyzing:

Part complexity: Flat bends may suit press brake forming, while hollow or contoured shapes demand deep drawing or hydroforming.

Material behavior: Forming aluminum or forming steel sheet requires different press tonnage and die profiles.

Annual volumes: Low volumes favor bending or CNC-based methods; high volumes justify stamping or forging tool investment.

Secondary operations: Welding, powder coating, and assembly impact sequence design and cost.

Below is a reference table we often share during the quoting phase:

| Forming Process | Best For | Tooling Cost | Volume Suitability | Cycle Speed |

|---|---|---|---|---|

| Bending | Panels, Brackets | Low | Low to Medium | Fast |

| Deep Drawing | Enclosures, Tanks | Medium | Medium to High | Moderate |

| Forging | Load Parts | High | High Only | Fast |

| Hydroforming | Tubular Parts | Medium | Medium | Slower |

| Stamping | Flat Complex | High | Very High | Very Fast |

This practical assessment helps our buyers avoid overengineering, reduce total cost of ownership, and keep product launches on schedule.

From Engineering to Mass Production: What Procurement Really Needs to Know

For overseas buyers, a forming process is only as good as the supplier’s ability to deliver consistently and professionally. At YISHANG, we focus not just on shaping metal, but on providing clear communication, predictable schedules, and full export support.

What Sets YISHANG Apart

MOQ Flexibility: We support order volumes from 50 pcs for prototypes up to 100,000+ pcs for production runs.

Reliable Lead Times: Standard prototypes within 7–10 business days, and production delivery in 20–30 days, depending on tooling and complexity.

Certifications You Can Trust: We’re ISO 9001 and RoHS certified, and can provide REACH, CE, or customs documentation as needed.

Comprehensive QC: Our inspection includes 100% visual checks, random dimensional verification, and functional validation as required.

Export-Grade Packaging: We provide anti-rust protection, custom cartons, palletizing, and regional compliance labeling.

Buyers working across multiple production cycles appreciate our ability to maintain tight version control, support reorders, and align delivery with regional warehousing schedules.

Conclusion: Forming Should Work for You—Not Against You

Metal forming is not just a technical process—it’s a strategic enabler for global buyers seeking scalable, high-performance parts. The right forming method, combined with an experienced supplier, leads to better margins, faster market access, and fewer production headaches.

At YISHANG, we don’t just manufacture parts—we work as procurement partners, helping our clients across Europe, North America, Southeast Asia, and beyond achieve smoother launches, higher consistency, and lower landed costs.

Whether you’re launching a new product line or optimizing an existing one, we invite you to leverage our forming expertise and take your supply chain to the next level.

📩 Contact us today to get a quote, submit a design, or request a technical consultation.

Let’s make your forming process simpler, smarter, and globally scalable.

FAQ

1. Do you accept RFQs with multiple item specifications in one order?

Yes. At YISHANG, we frequently handle RFQs involving multi-item projects, including different materials, forming methods, and surface treatments. We consolidate these into a unified quote and delivery schedule, helping procurement teams save time and streamline logistics.

2. What is your typical lead time for OEM sheet metal forming orders?

Standard lead times are:

Prototyping: 7–10 working days

Mass production: 20–30 days based on complexity

Expedited service: Available for time-sensitive requests

We also provide progress tracking, so clients can monitor production milestones.

3. Can I get forming services with customized packaging and international shipping support?

Absolutely. Our export solutions include:

Custom-sized cartons with labels and barcodes

Foam inserts, plastic wraps, or anti-rust coatings

Wooden crates or palletized shipments

International freight coordination and customs documentation

We’ve supported buyers across Europe, North America, and the Middle East with tailored shipping solutions.

4.What is forming in manufacturing?

Forming in manufacturing refers to reshaping metal parts through force without removing material. It includes methods like forging, bending, and stamping to create structural or enclosure parts.

5.How does metal forming compare to machining?

Forming is faster, more material-efficient, and better suited for mass production, while machining allows for higher precision but generates more scrap.