What Is Molding — And Why It Matters to Global Procurement

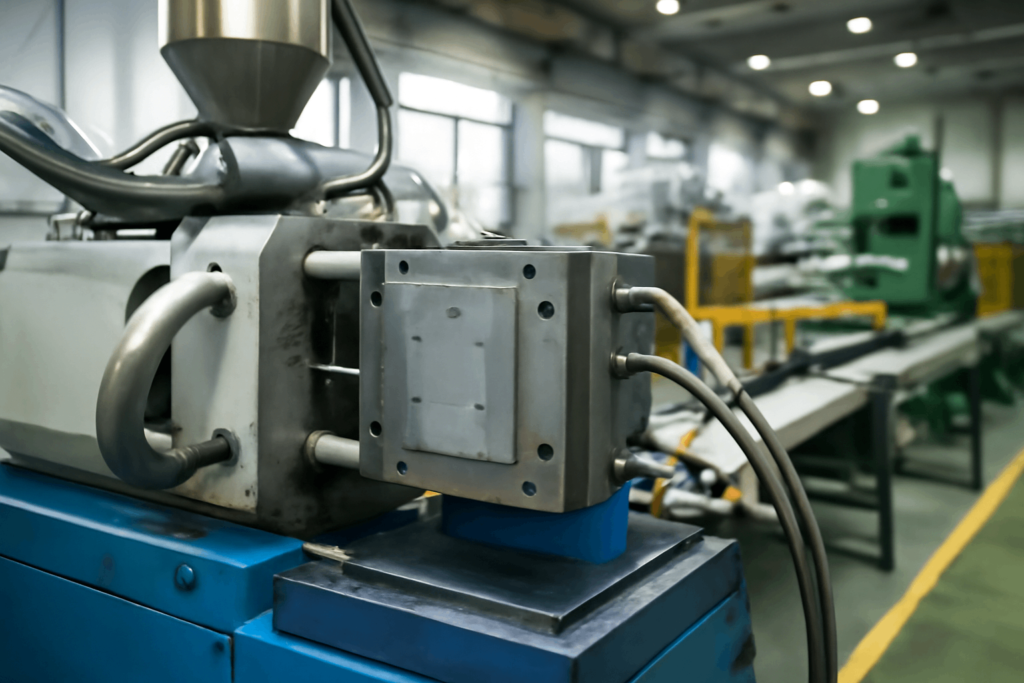

Molding shapes materials like plastic, metal, or composites into functional parts using heat, pressure, and a mold. For buyers, understanding what is molding helps evaluate if a supplier can deliver consistent, scalable production that aligns with cost, quality, and delivery expectations.

The Mechanics of Molding: Material, Mold, and Performance

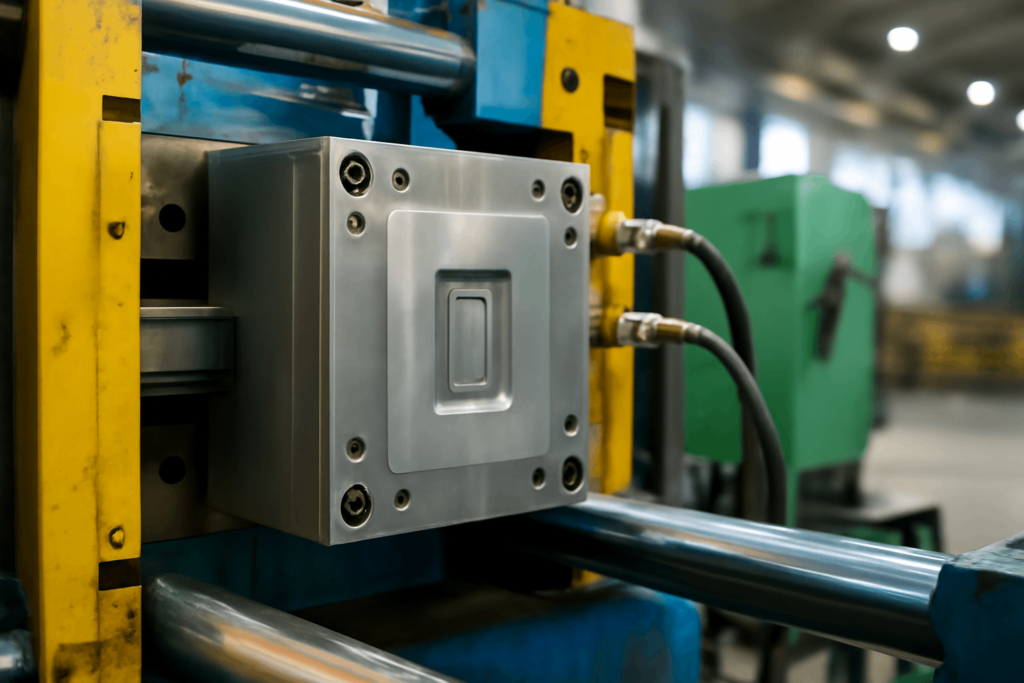

The process involves transferring molten or pressurized material into a mold cavity, where it cools or cures into the final shape.

The quality of a molded part depends on how well the material flows, fills the cavity, and interacts with the mold surface. For example, ABS molding requires temperature stability and balanced flow to avoid visible defects or structural stress.

Aluminum casting techniques benefit from controlled thermal cycling to prevent shrinkage or internal cracking—especially in thin-walled or load-bearing parts. This makes it well-suited for industrial sheet metal forming where precision is key.

Key influencing variables include:

Mold temperature and cooling time

Injection speed and holding pressure

Material shrinkage and part geometry

These factors determine not only surface finish and strength but also cycle time and scrap rate, all of which matter to cost and reliability.

Types of Molding: Matching Process to Product Need

Choosing the right fabrication technique saves time and capital. Let’s explore different shaping processes from a production planning viewpoint.

Injection Molding

Best for high-precision, high-volume plastic parts like electronic housings, trays, and branded components.

Compatible with ABS, PC, Nylon, and more

Aluminium injection machines reduce weight and energy load

Tooling costs high upfront but offer the lowest per-unit cost for 100k+ units

Ideal for mass-production buyers sourcing custom aluminum moldings for export

Compression Molding vs. Injection Molding

Compression processes suit large parts (panels, appliance bases) with fewer intricate features. It uses pressure and heat to form material inside a heated cavity.

Injection molding, by contrast, suits complex geometries and fast cycle times. The 2 shot molding process (two materials injected in sequence) allows multi-functionality in a single part—useful in power tools or automotive assemblies.

Blow Molding, Rotational Molding, Extrusion

Blow mold techniques create hollow items (bottles, tanks)

Rotational methods enable large-volume, seamless components

Extrusion suits continuous profiles like trim, pipes

The access for molten metal into molds—via gating systems—is especially critical for aluminium mold and pattern designs, where internal stress can jeopardize structural integrity.

Material-Process Fit: The Real Cost Control Lever

Choosing the right material is more than matching specs—it drives tooling decisions, mold wear, and defect rate.

| Material | Use Cases | Matching Process |

|---|---|---|

| ABS | casings, modular parts | Injection (ABS molded parts) |

| Polycarbonate | optical & impact components | 2 shot molding process |

| Epoxy, Phenolic | thermal/electric insulators | Transfer or compression |

| Aluminum | structural frames, signage | Aluminium mold or casting |

Using aluminum molds for injection improves cycle time by up to 30%, but aluminum injection mold tool life is shorter than hardened steel (typically ~100,000 cycles vs. 1 million).

➡️ For medium-volume production, aluminum molds are ideal. For small-scale custom runs, casting may offer better ROI due to lower tooling commitment. For buyers exploring low-volume aluminum forming, this balance between flexibility and investment becomes critical.

Bioplastics and silicone components require vented tooling and controlled moisture; many buyers opt for advanced prototype forming to validate designs before scaling.

Strategic Advantages: Tooling as a Cost Management Asset

Tooling decisions influence cost and quality far beyond the first batch. Buyers often overlook that the mold—not just the machine—dictates per-part consistency. Accurate forms reduce flash, warpage, and post-processing.

Cost of injection molding is primarily affected by:

Mold type (aluminum vs. steel)

Cavity count

Design complexity

Projected lifespan (e.g., aluminum injection molds vs. H13 steel tools)

🧮 Tool amortization tip: For aluminum tools, we recommend a minimum MOQ of 10,000–30,000 units to optimize per-part cost. Steel molds suit 100,000+ production with long-term durability.

High-performance molds made in-house reduce lead times and allow design adjustments without third-party delays. Advanced forming technologies such as AI molds and sensor-integrated tooling are now available for predictive maintenance.

Design Best Practices: Collaborating for Moldable Success

Optimize Geometry for Moldability

Maintain wall thickness uniformity (±10%)

Avoid undercuts where not essential

Apply draft angles (2–3°) to vertical surfaces

Engineering-Procurement Collaboration

Software like Moldex3D and Fusion360 help optimize cavity formation, predict warping, and simulate cooling cycles. It’s standard to run at least one DFM review and one pilot mold trial before going full-scale.

Designing injection molded parts without mold flow consideration leads to costly reworks. With tolerances as tight as 0.05–0.1mm, accurate tools are the foundation of repeatable quality.

If you’re considering sheet metal forming for industrial enclosures, early collaboration between your engineering and sourcing teams ensures parts meet functional and cost requirements.

Cost, Volume, and Method: Making Informed Tradeoffs

| Process | Batch Size | Tooling Cost | Unit Cost | Lead Time |

| Injection | 10k+ | High | Low | 3–6 wks |

| Compression | 1k–10k | Medium | Medium | 2–4 wks |

| Casting | <1k | Low | High | 1–3 wks |

| 3D Printing | <500 | Minimal | High | 2–5 days |

Casting processes suit prototyping or low runs. For cost-effective scale, aluminum-based tools are often used in combination with hybrid strategies—like 3D printed pilot runs + aluminum mold for full production.

🎯 Recommendation: Casting fits small-lot agility. For growing volumes, switch to aluminum tooling to balance cost and cycle time. Match MOQ to your tooling ROI expectations. If you’re assessing sheet metal forming vs injection, consider surface detail, volume, and lead time constraints.

Industry Trends: Efficiency, Intelligence, and Sustainability

Smart Manufacturing

Smart production tools like AI molds and digital twin simulations are gaining adoption among advanced prototype forming providers. Cavity pressure sensors now alert real-time anomalies.

Green Molding

Green initiatives are also driving the use of biodegradable resins, recyclable aluminum base molds, and optimized runner systems to reduce plastic waste.

📉 With aluminum molds for injection, buyers reduce energy load and enable faster startup cycles—valuable in time-sensitive industrial sectors.

OEM aluminum mold factory capabilities are also expanding globally, making it easier for overseas buyers to prototype and scale with regional partners.

Final Takeaway: Precision in Process, Profit in Planning

For global buyers, manufacturing method choices determine production efficiency, quality, and supply resilience.

Whether sourcing high-tolerance brackets or low-volume ABS molded trays, the key lies in choosing a process aligned to your volume, material, and tolerance needs.

Matching the process to part demand ensures cost-effective procurement. Work with partners who understand how to reduce tooling cost for metal components and help streamline your supply chain.