Introduction

Tampo printing, also known as pad printing, is a specialized method that enables precise marking on three-dimensional parts and irregular surfaces. For overseas B2B buyers—particularly wholesalers and procurement managers—consistency, scalability, and compliance are critical in component sourcing. Whether it’s a vending machine panel or medical housing, printed marks must withstand transport, usage, and inspection.

This article explores tampo printing from the perspective of global sourcing. You’ll understand what makes it a strategic process for component-level branding, regulatory labeling, and efficient production. It’s crafted to help procurement professionals evaluate suppliers, production reliability, and long-term compatibility.

Why Tampo Printing is a Strategic Fit for Industrial Procurement

Buyers evaluating a new supplier or factory focus on repeatability, material range, and output quality. Tampo printing delivers on these priorities, especially for products requiring detailed, durable branding.

Because it performs well on metal, plastic, and coated surfaces—even when curved—tampo printing minimizes the risk of rejected batches. This helps cut waste and ensures visual consistency across thousands of units.

From CE-compliant icons to multi-color branding, tampo printing meets various regional standards and buyer requirements. Its integration into OEM/ODM production workflows means greater traceability and fewer pre-shipment inspection issues.

What is Tampo (Pad) Printing? From Swiss Origins to Scalable Production

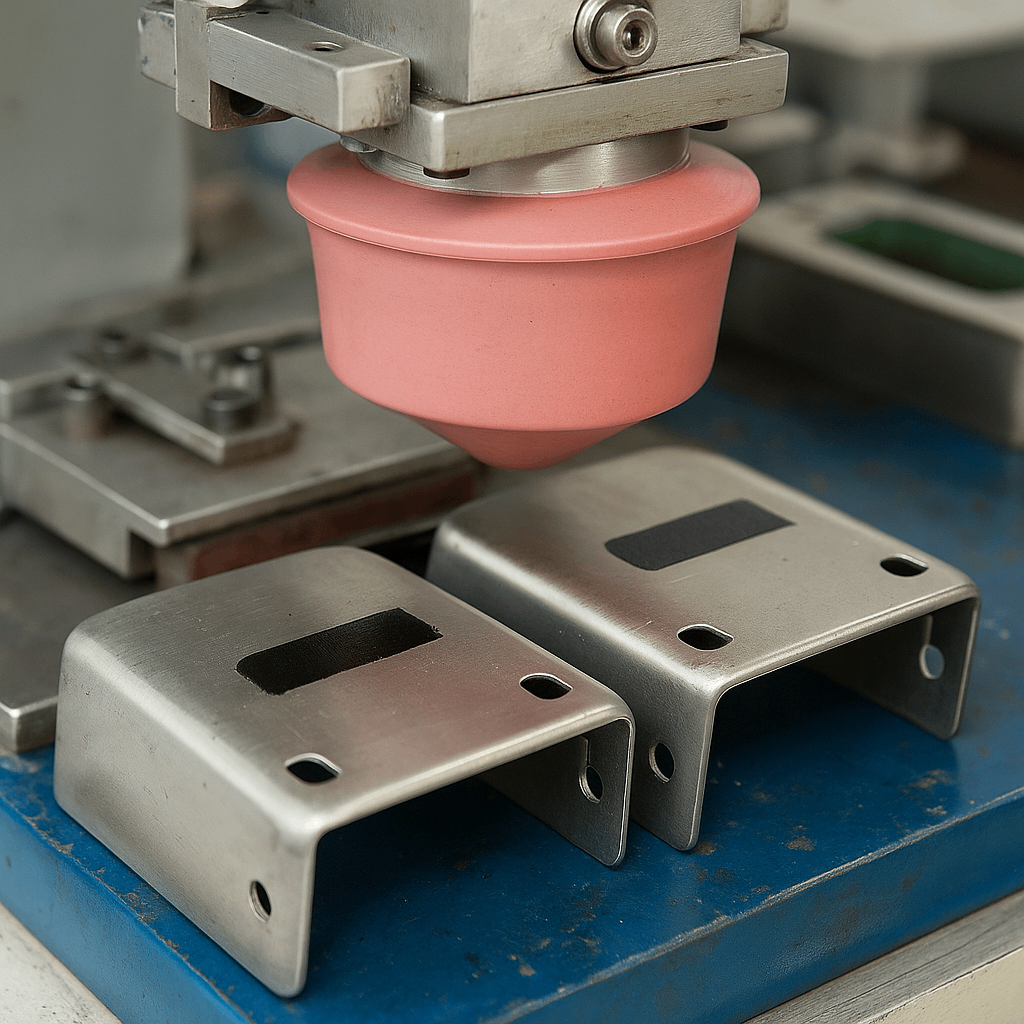

Tampo printing was developed in the Swiss watch industry to mark miniature dials with precision. Today, it’s a robust, automated process for transferring logos, icons, or text onto irregular-shaped parts using a flexible silicone pad.

This indirect offset method enables clean transfers without requiring flat surfaces. It’s ideal for sectors like electronics, automotive, and industrial hardware. Unlike screen or digital printing, tampo adapts to part geometry with minimal distortion.

Modern pad printing machines feature automation and alignment systems. YISHANG, for instance, employs robotic pad changers and inline quality sensors to keep deviation under 0.05 mm—vital for global buyers seeking consistency at scale.

How the Tampo Printing Process Works—In Terms Buyers Should Know

The core process involves transferring ink from an etched metal plate (cliché) to a component via a silicone pad. This setup allows high accuracy in ink placement, thickness, and edge definition.

What matters to procurement teams is process control. Because the ink partially evaporates during pickup, it adheres reliably without smearing. This ensures data matrix codes, serials, and instructional icons remain legible after shipping and assembly.

Scalability also matters. Tampo systems scale from low-volume jigs to high-speed, multi-color rotary stations. For buyers handling global distribution, this flexibility ensures supply continuity across product variants.

Core Elements for Reliable Tampo Print Output

Material Compatibility & Pre-Treatment

Tampo printing supports various substrates: stainless steel, aluminum, ABS, polycarbonate, and powder-coated metal. However, adhesion requires correct surface energy. Treatments like flame or corona discharge are commonly applied.

This step is especially important for high-friction products like switches, battery casings, or control panels. For B2B buyers, this translates to reduced RMA rates and stronger end-user satisfaction.

Ink Selection & Regulatory Fit

Pad printing inks include solvent-based and UV-curable options. Each offers distinct benefits: solvent inks for strong adhesion on metal; UV inks for fast curing and low VOC compliance.

Buyers in regulated sectors (cosmetics, medical, electronics) should request RoHS- or REACH-compliant ink specs. YISHANG routinely supplies inks that pass CE, FDA, and ISO labeling tests for global markets.

Solving Real-World Production Needs with Tampo Printing

Small Format Legibility

Many B2B clients—especially in medical or electronics—need markings under 2 mm high. Tampo printing supports resolutions up to 600 dpi, suitable for barcodes, serials, and micro logos.

This is crucial for international traceability, customs compliance, and warranty tracking. Even better, it maintains precision across textured and angled surfaces.

3D and Irregular Surface Coverage

Unlike digital or laser systems, tampo printing accommodates angles and curves. The deformable pad ensures even ink transfer, minimizing distortion.

This matters in automotive knobs, panel buttons, or industrial housings. By reducing rejects, you save inspection time and material costs.

Multi-Color Branding that Endures

In markets like tools, appliances, or vending hardware, brand visibility must last years. Multi-pass tampo printing enables crisp, layered color with tolerances under 0.05 mm.

UV- and abrasion-resistant inks extend brand life without peeling. For procurement, it means fewer field failures and stronger product presentation.

Legal and Functional Labeling

For sectors like foodservice or power equipment, compliance symbols must remain intact. Pad printing enables permanent, standardized labeling—even on curved or coated parts.

At YISHANG, customers sourcing for export often require UL, CE, or ISO marks to pass audits. We support this through certified inks and cleanroom-compatible processes.

Why Tampo Outperforms Other Printing Techniques in Procurement Contexts

| Feature | Tampo Printing | Screen Printing | Digital Printing |

|---|---|---|---|

| 3D Surface Compatibility | ✔ Excellent | ✖ Poor | ✖ Limited |

| Resolution (dpi) | ✔ Up to 600 | ✖ ~200 | ✔ ~300 |

| Multi-Color Accuracy | ✔ High | ✖ Low | ✔ Moderate |

| Compliance-Grade Output | ✔ Yes | ✔ Conditional | ✖ Inconsistent |

| Unit Cost (mass production) | ✔ Low | ✖ High Labor | ✖ High Setup |

In procurement terms, tampo printing minimizes failure points and maximizes visual and regulatory performance. It’s the most versatile solution for part marking across industries.

Evaluating a Supplier’s Tampo Printing Capabilities

Before onboarding a factory, buyers should verify how they handle adhesion, registration, and defect rates. Common issues like ghosting or misalignment often reflect poor pad selection or humidity control.

Ask for test prints, pad specs, and ink documentation. A reliable supplier should be able to explain pad Shore hardness selection (typically ranging from 40–70), substrate pre-treatment methods, and minimum line width standards (≥0.1 mm) for sharp transfers.

They should also provide evidence of ink curing methods (UV or solvent) and relevant compliance certifications like RoHS or REACH. At YISHANG, we deliver adhesion test reports, curing logs, and process validation to support buyer audits and product certifications.

Strong tampo setups reduce post-inspection corrections, ensuring faster go-to-market cycles and smoother order fulfillment.

Ready for Growth: Can Tampo Scale with Demand?

One of the biggest sourcing concerns is whether a supplier can handle volume spikes. Tampo printing systems scale easily—from 500 pieces to 100,000+ batches—without losing accuracy.

At YISHANG, we integrate tampo printing into broader CNC and assembly workflows. Smart systems track pad wear and ink consistency, supporting lean manufacturing and batch traceability.

With closed ink cup tech and RoHS-certified inks, we also align with global ESG and import compliance standards.

Conclusion: Smart Marking Starts with the Right Printing Partner

Tampo printing delivers what sourcing professionals demand: brand clarity, production consistency, and compliance across regions and sectors.

When executed by an experienced team, it’s more than a decoration method—it’s a safeguard for global product quality.