Why Welding Matters in Modern Metal Product Sourcing

Quick definition: what is welding, and what are welds?

Welding is a fabrication process in which two or more parts are fused together by heat, pressure, or both so that, after cooling, they behave like a single piece. In metal fabrication, the fused area is called the weld, and the overall operation is called the weld process. Compared with low‑temperature joining methods, welding creates joints strong enough for structural, load‑bearing, and long‑life industrial applications.

When buyers search for welding information, they are usually not trying to become welders. They want to know what welds do inside a product, how welding affects quality, and what welding is used for in real‑world assemblies they purchase at scale. With that in mind, this article looks at welding from a sourcing and quality‑control angle, not from a training‑manual angle.

For professional importers and wholesale buyers, the question “what is welding used for” is really a question about product reliability, consistency, and long‑term performance. In a photo, two welded frames or cabinets can look almost identical. In the field, however, differences in weld quality show up as alignment issues, sealing failures, structural problems, and higher claim rates.

From a sourcing perspective, what welds do inside a product is more important than how welds look in a brochure. This article focuses on welding information that helps you make better purchasing decisions: what welds are, how the weld process affects real products, how to assess welded assemblies, and how welding capability separates ordinary suppliers from long‑term partners.

The content is written for overseas B2B buyers — not for welding technicians. Terminology is kept clear and practical, and every section links technical factors to purchasing outcomes such as lifetime cost, risk, and customer satisfaction.

I. Why Welded Products Matter to Wholesale Buyers

Strong Welds Create Predictable Structural Behavior

Most metal products fail at the joints — not the flat panels or tubes, but the welded areas where forces are concentrated. When welding is controlled and appropriate for the design, the product behaves like a unified structure. When it is not, alignment shifts, cracks appear, and components deform under everyday loads.

For buyers sourcing cabinets, frames, racks, carts, display structures, or housings, welding directly influences:

- Whether a frame stays straight after transport and installation

- Whether a cabinet door remains aligned with its frame over time

- Whether a heavy‑duty rack or platform handles repeated loading without distortion

Predictability is the key word. A stable weld process reduces performance variability between units and batches. That matters greatly when you are planning multi‑container shipments or supplying demanding end users.

Welding Drives Accuracy and Batch‑to‑Batch Consistency

Heat input during welding changes metal shape. Without proper control of parameters, sequence, and fixturing, heat causes twisting, bowing, and angular misalignment. Many buyers have experienced situations where parts “look fine but do not fit properly” once they reach assembly.

Tight dimensional control is not a nice‑to‑have in OEM or ODM projects; it is a minimum requirement. Consistency of welded dimensions affects:

- Assembly speed at your or your customer’s factory

- Interchangeability of parts across batches

- Effectiveness of jigs, fixtures, and automated assembly equipment

In this sense, welding is not only about strength. It is also about precision. A supplier’s control over the weld process is a key predictor of batch consistency and long‑term cooperation potential.

Welding Determines Long‑Term Durability

Over time, welded joints experience dynamic stresses: vibration from machines, impact from handling, and cycles of loading and unloading. Products that look similar in marketing photos can have very different lifetimes when weld penetration, joint design, and material choice are not properly matched.

A buyer’s long‑term cost efficiency depends strongly on this hidden layer of quality. When two suppliers quote the same drawing at different prices, weld capability is often the main factor behind differences in durability, warranty performance, and field failure rates. Understanding what welds are doing mechanically inside the product helps you interpret those price differences more accurately.

II. What Is Welding Used For Inside a Metal Product

1. Structural Continuity

Welding turns separate components into a structurally continuous whole. Instead of relying on bolts or rivets at discrete points, welds create a continuous metal bridge between parts. This eliminates many sharp stress concentrations and allows forces to flow more evenly through the structure.

For buyers, this means:

- Higher usable load capacity with the same material thickness

- Fewer permanent deformation issues under real loads

- More reliable performance in high‑duty or safety‑critical applications

This is particularly important for racks, frames, chassis, support structures, and industrial fixtures, where poor welds create safety risk and increase the probability of unexpected failures.

2. Sealing and Environmental Protection

In many products, welds must also act as a barrier. Metal housings in energy storage, vending, telecom, or automation systems rely on controlled weld seams to achieve dust protection, water resistance, and correct gasket compression. In these cases, what welding is used for goes beyond structure — it also defines environmental protection.

A single porous or incomplete weld can cause:

- IP rating test failures during product certification

- Water or dust ingress during real‑world operation

- Corrosion that originates at weld points and spreads

For buyers working with sealed enclosures or outdoor equipment, understanding weld quality in sealing areas is essential for evaluating supplier capability and risk.

3. Vibration and Fatigue Resistance

Products that move or carry repeated loads need welds that survive cyclic stress. Weak welds crack gradually and can cause sudden breakage, even if the initial static tests were acceptable.

Reliable welds in fatigue‑sensitive products help to:

- Extend service life in demanding environments

- Reduce warranty and service claims

- Maintain structural alignment under vibration or shock

Repeated load behavior is often under‑evaluated in early sourcing discussions, but it is one of the most critical factors for long‑term customer satisfaction.

III. Real‑World Scenarios That Affect Buyer Outcomes

1. Structural Products That Must Stay Aligned

Small distortions become large problems when doors, drawers, mounting points, or mating parts do not align. These issues often appear only after shipping, handling, and final assembly. From a buyer’s point of view, they show up as complaints, delays, and extra labour.

Typical pain points include:

- Frame twist affecting installation on uneven floors

- Doors that do not close smoothly or require adjustment

- Shelves that sit unevenly or rock under load

- Mounting holes that no longer align with reference points

These are usually not drawing errors. They come from weld sequence, fixturing quality, and heat management. When evaluating suppliers, it is worth checking not just the first article, but multiple pieces from a pilot batch, to see whether welded assemblies remain straight after welding and cooling.

2. Protective Enclosures for Sensitive Equipment

Sealed metal products often fail for subtle reasons. A weld bead that looks visually acceptable may still allow dust or moisture to pass through microscopic pores or incomplete fusion zones.

Buyers supplying energy storage systems, smart vending machines, telecom cabinets, or automation controls face real consequences when welds do not seal as expected:

- Repeated IP test failures during certification

- Customer complaints about water ingress or condensation

- Early corrosion starting along weld lines or corners

In these applications, welds are used both for mechanical structure and for sealing performance. Buyers should consider requesting specific information on sealing welds, such as weld maps for critical seams or basic leak test results for sample units.

3. Heavy‑Duty Frames and Machinery Components

In heavy‑use environments, weld failure is one of the most common root causes of structural problems. Products like industrial carts, material‑handling racks, agricultural frames, logistics platforms, and machine bases are exposed to repeated impacts, shocks, and changing loads.

Deep, continuous welds with proper joint preparation and penetration significantly reduce the likelihood of fatigue cracks. When these products are used around people or expensive equipment, weld quality is more than a technical detail — it becomes a safety and liability factor. Buyers can protect themselves by assessing how suppliers design and qualify welds for heavy‑duty applications.

IV. How Weld Quality Shapes Final Product Performance

1. Load Paths and Stress Distribution

A welded product is only as strong as the way forces travel through it. Welding determines those load paths. Well‑designed and well‑executed welds follow the structural logic of the design; poorly placed or shallow welds force stresses into sharp corners or thin areas.

Buyers evaluating welded assemblies can ask:

- Do welds follow the main load paths in the design, or are they placed mainly for convenience?

- Does weld length and penetration match the expected load case?

- Are high‑stress areas reinforced by welds, or weakened by cutouts and joints?

Suppliers who understand load paths can often reduce material usage while still achieving the required performance, creating a more efficient product and a more competitive offer.

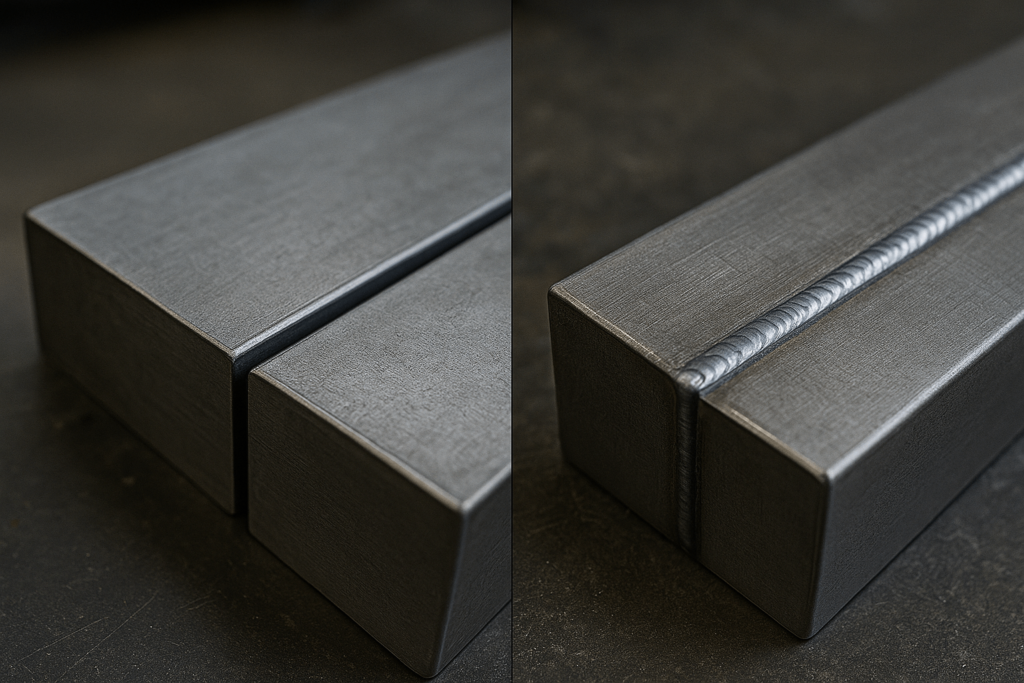

2. Dimensional Accuracy and Distortion Management

Distortion is one of the most frequent real‑world causes of assembly issues. Welding affects dimensions more than cutting or forming because heat changes the shape of the entire welded zone.

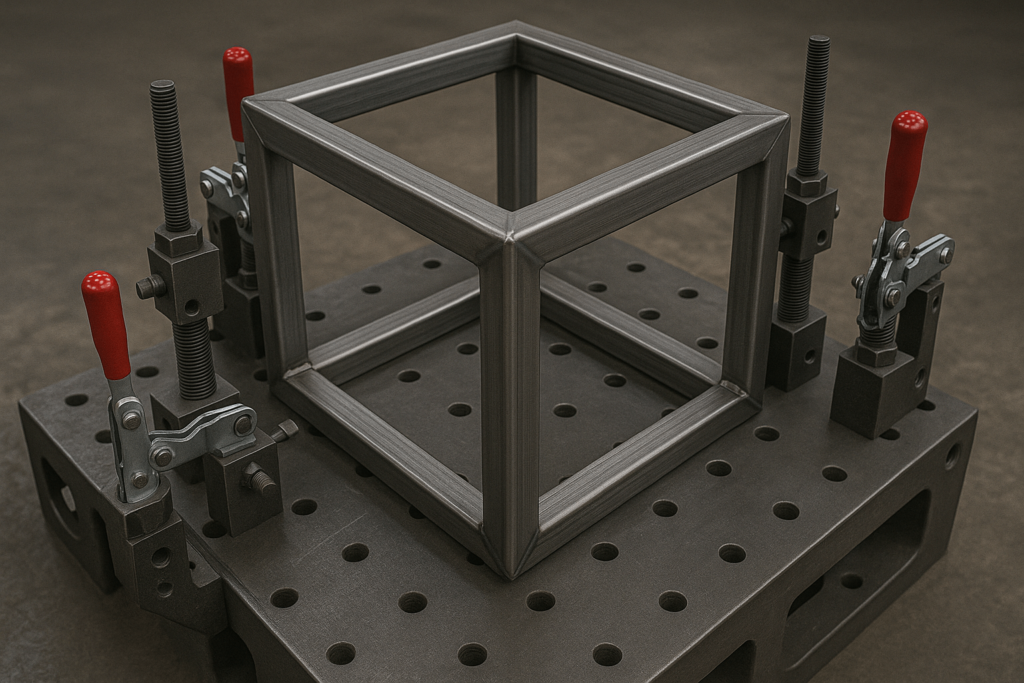

Professional suppliers control distortion through a combination of:

- Controlled heat input and travel speed

- Carefully planned welding sequence

- Rigid fixturing and clamping

- Sufficient cooling time and intermediate checks

For buyers, the impact can be summarized as follows:

| Factor | Buyer Impact | Common Issue |

|---|---|---|

| Heat input | Alignment stability | Twist / warp |

| Sequence | Fit and gap consistency | Uneven gaps at joints |

| Fixturing | Batch repeatability | Variation across batches |

| Penetration | Structural strength & life | Cracks or early failure |

Evaluating a supplier’s approach to distortion control — for example, by discussing fixtures or reviewing pilot batch results — helps buyers avoid costly line‑stop situations and time‑consuming rework.

3. Surface Quality and Finish Compatibility

Welds strongly influence powder coating, painting, polishing, or anodizing. Even when a product is structurally sound, surface imperfections around welds can lead to coating defects and early corrosion.

Common finish‑related issues caused by welds include:

- Coating pinholes and bubbles where gas escaped from porous welds

- Visible weld marks or grinding lines through paint

- Rust forming on or near welds on carbon steel products

For customer‑facing products, good weld finishing improves perceived quality and reduces the amount of post‑weld grinding work. From a sourcing perspective, checking weld appearance and finish on real samples is an efficient way to judge process stability before committing to larger orders.

V. Choosing the Right Welding Approach (Buyer Perspective)

1. Align Welding With Product Requirements

Rather than starting from a list of processes, buyers get better results by first clarifying functional requirements. Key points include:

- Structural load and safety level

- Sealing and environmental exposure

- Visible or hidden weld locations

- Assembly method and tolerance needs

- Order volume and repeat frequency

These parameters determine whether a particular weld process — such as TIG, MIG, laser, or spot welding — is suitable. For example, TIG may be preferred for thin stainless steel with visible corners, while MIG may be more cost‑effective for thick carbon‑steel frames.

2. Match Welding Strategy to Material Behavior

Different metals behave differently under heat. A knowledgeable supplier adjusts the weld process, parameters, and joint design according to material type and thickness.

Typical considerations include:

- Stainless steel: needs low heat input and controlled cooling to avoid distortion and discoloration.

- Carbon steel: tolerates higher heat and supports deeper penetration, ideal for structural applications.

- Aluminum: conducts heat quickly, so distortion control and proper filler selection are important.

- Non‑ferrous metals: may require specific preparation and parameter windows to achieve sound welds.

Material‑specific expertise in welded assemblies is a strong indicator that a supplier understands not just what welding is, but how to use it correctly for different applications.

3. Prioritize DFM (Design for Manufacturability)

Design decisions determine welding outcomes more than equipment lists do. Buyers benefit when suppliers participate in Design for Manufacturability discussions early in a project.

Key DFM topics include:

- Joint access for welding and inspection

- Weld geometry and location relative to load paths

- Control of the heat‑affected zone

- Tolerance stack‑ups across welded sub‑assemblies

By aligning design and welding capability from the start, buyers reduce the risk of surprises when the project scales from sample to mass production.

VI. Welding Trends That Matter in Global Sourcing

1. Precision Welding for Thin Metals

As many industries shift to lighter, more compact metal housings, precision welding becomes a core requirement. Thin sheets are more sensitive to heat, and even small distortions can cause functional issues such as doors not closing or seals not engaging properly.

Buyers in energy storage, electronics, and compact machinery should pay particular attention to how suppliers handle thin‑metal welds. Reviewing real samples, asking about fixturing, and checking for distortion around welds are practical steps.

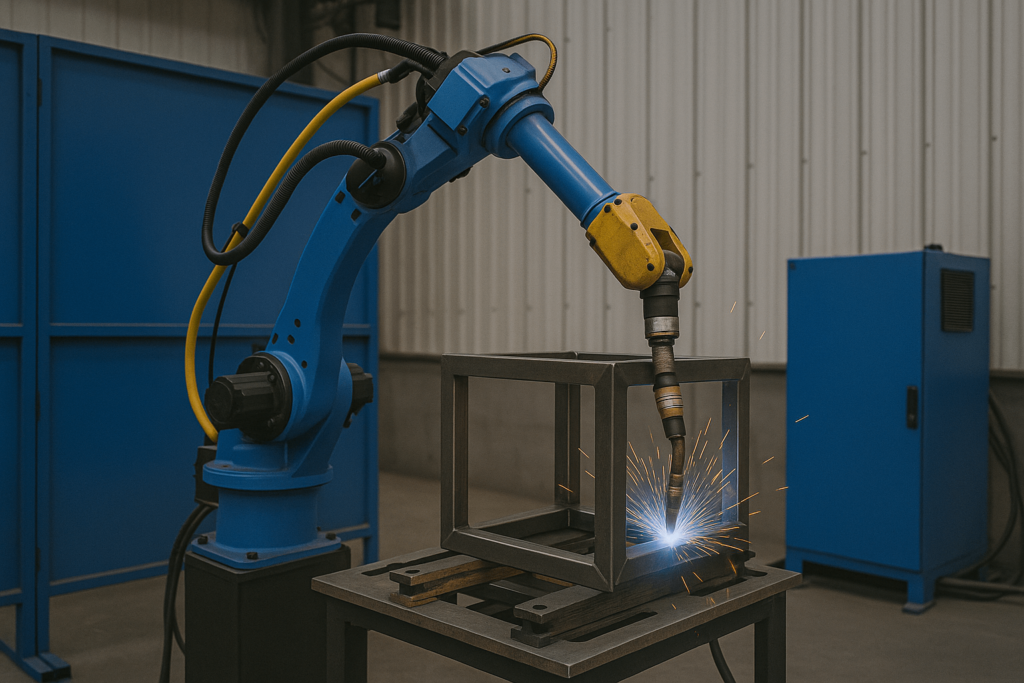

2. Robotic Welding for High‑Volume Stability

Robotic welding and automated fixtures are increasingly common in metal fabrication. For recurring orders, automation offers:

- Lower variation between pieces and batches

- Better documentation of weld parameters

- Higher throughput once programming is established

When evaluating long‑term suppliers, it is useful to understand which product families benefit from robotic welding and how the supplier decides when to automate.

3. Higher Surface Expectations

Even in historically utilitarian markets, expectations for appearance and finish are rising. End users increasingly notice weld quality, corner finishing, and coating smoothness.

Processes such as TIG finishing, laser welding, and fine grinding help meet these expectations. Buyers targeting higher‑end or visible applications should include weld appearance and surface smoothness in their quality standards.

4. Quality Documentation and Traceability

Many buyers now expect structured documentation around weld quality. Depending on the application, this can include:

- Welding Procedure Specifications (WPS)

- Operator qualification or training records

- Basic NDT results (such as dye‑penetrant checks on critical joints)

- Dimensional inspection reports for welded assemblies

Suppliers able to provide this level of documentation significantly reduce sourcing risk and demonstrate a more mature quality system.

VII. Practical Checklist: Questions to Ask About Welds

Many high‑ranking articles on welds and welding uses stop at general explanations. For wholesale buyers, it is more useful to turn that knowledge into a simple checklist. The questions below are structured to help you compare suppliers and quickly identify who really controls their weld process.

1. Questions about weld process and capability

- Which weld processes do you use for this product, and why?

A professional answer will connect the weld process (for example, MIG for structural frames or TIG for thin stainless housings) to material type, thickness, and required appearance. - How do you qualify welders and keep parameters consistent?

Look for mention of written procedures, training or certification, and some form of weld parameter control, not just “our welders are experienced.” - Can you show examples of similar welded metal products you already supply?

Real photo evidence of welded assemblies close to your specification is more valuable than generic factory images.

2. Questions about distortion, accuracy, and finish

- How do you control distortion on this design?

Strong suppliers can explain their fixturing approach, weld sequence, and any design changes that help manage heat input. - What tolerances do you normally achieve on welded assemblies?

Compare their answer to your own drawing and functional requirements. Dimensional stability is often where sourcing problems appear first. - How do you prepare welds for powder coating or painting?

Answers that mention cleaning, grinding where necessary, and visual inspection of welds before coating indicate a more complete process.

3. Questions about inspection and welding information

- What in‑process or final checks do you perform on welds?

Even simple visual inspection standards, go/no‑go gauges, or basic dye‑penetrant testing on critical joints show that welding inspection is taken seriously. - Can you share any welding information or reports for pilot batches?

For important projects, asking for basic weld records, inspection photos, or dimensional reports on welded metal components can provide early reassurance. - How do you handle non‑conforming welds in production?

Look for a clear, structured answer that mentions containment, rework, and corrective action, not only “we repair them when we see them.”

These questions do not turn buyers into welding engineers, but they do create a practical framework for evaluating welding quality and supplier maturity.

VIII. Buyer‑Focused FAQs

How can I assess weld durability before placing a large order?

Request sample weld cuts or cross‑section photos to check penetration and fusion. Ask about any NDT methods used on critical joints and compare multiple samples for consistency.

Why do similar drawings produce different results from different suppliers?

Because welding outcomes depend on preparation, sequence, fixturing, operator skill, and inspection — not only on the design. Two factories can read the same drawing but execute completely different weld processes.

Which welding approaches fit thin housings and enclosures?

TIG, controlled MIG, or laser welding are often preferred for thin metals, as they allow better distortion control and cleaner bead appearance.

What drives welding cost most?

Material type, metal thickness, weld length, joint complexity, finishing requirements, and inspection level all play a role. Lower prices achieved by cutting corners on welding often show up later as higher field failure or rework cost.

How do welds affect coating and corrosion resistance?

Smooth, fully fused welds that are properly cleaned support uniform coating and slow down corrosion. Poor welds with porosity or heavy grinding marks tend to produce coating defects and become early rust points.

IX. Conclusion — Welding as a Strategic Purchasing Factor

For wholesale and industrial buyers, welding is not just a technical detail on the factory floor. It is a strategic factor that predicts how metal products will perform, how stable your supply will be, and how your customers will experience your brand.

Understanding what welding is used for inside the product — to provide structural continuity, sealing, fatigue resistance, and a finishing base — gives you an advantage when comparing suppliers and evaluating offers.

If you are sourcing metal cabinets, frames, enclosures, or custom welded assemblies and want predictable, repeatable welding quality, YISHANG is ready to review your drawings and requirements and provide practical, fabrication‑oriented feedback for your projects.