Introduction

For global sourcing teams and wholesale buyers of fabricated metal parts, understanding a metal’s melting point isn’t just technical trivia—it’s a baseline for performance and reliability. Whether specifying custom housings for electronics or brackets for energy systems, knowing how different metals respond to heat directly affects product quality, durability, and safe usage across temperature-sensitive applications.

This guide is tailored for decision-makers in procurement, engineering, and quality control. Drawing from YISHANG’s 26+ years of experience in export-grade sheet metal manufacturing, we’ll explore not just what temperature does metal melt, but how that data impacts your RFQ specs, failure prevention strategy, and supplier evaluation process. We combine real-world experience, global standards, and relevant technical detail—all in one sourcing-focused reference.

What Is a Metal’s Melting Point—and Why It Matters in Global Procurement

A metal’s melting point is the temperature at which it transitions from solid to liquid under standard pressure. In practical sourcing scenarios, it dictates how a metal will behave during fabrication (e.g., cutting, forming, welding) and under operating heat loads.

For example, understanding what temperature does aluminum melt at (around 660°C) can help you evaluate whether a supplier’s process is suitable for parts used in ventilation housings or LED lighting structures. If a supplier fails to account for this during welding, warping or burn-through may occur.

Wholesale buyers also need to consider how ambient temperatures in transportation or field deployment could impact material behavior. In tropical zones, poorly selected metals may soften or deform during shipping. With melting points as your benchmark, material choices become measurable and defensible.

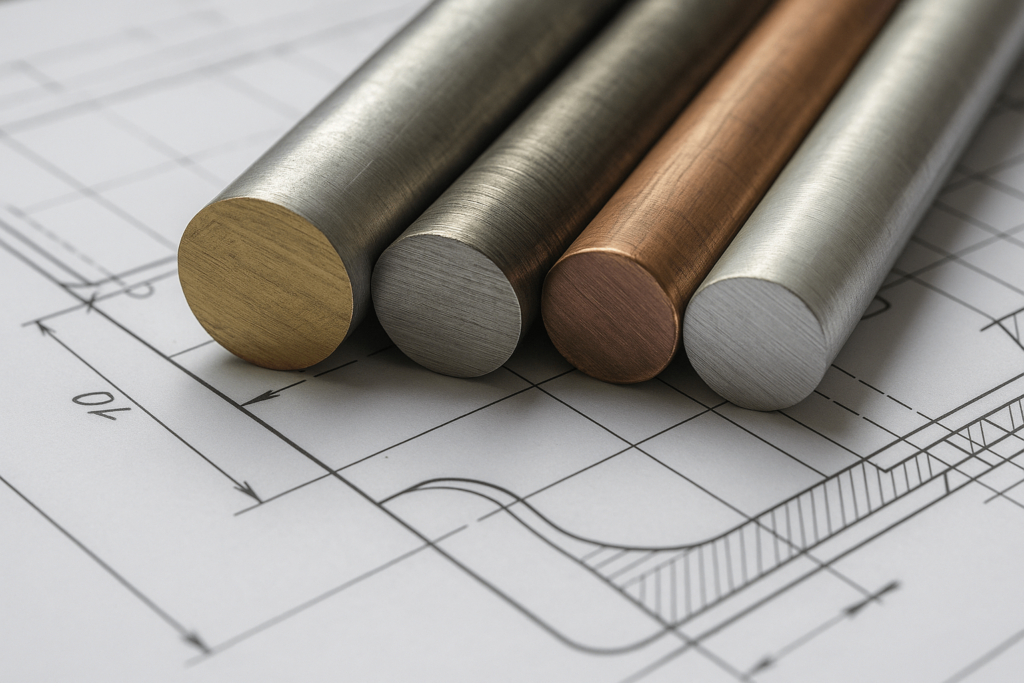

Melting Point Table for Common Metals and Alloys

Here is a technical summary of key melting points. These values help procurement specialists quickly compare material suitability for thermal use cases and compliance with engineering specs.

| Metal / Alloy | Melting Point (°C) | Melting Point (°F) |

|---|---|---|

| Aluminum (6061) | 582–652 | 1079–1206 |

| Brass | 930 – 940 | 1706 – 1724 |

| Bronze | 913 – 940 | 1675 – 1724 |

| Copper | 1085 | 1985 |

| Iron | 1538 | 2800 |

| Cast Iron | ~1200 – 1300 | 2192 – 2372 |

| Lead | 327 | 621 |

| Nickel | 1455 | 2651 |

| Stainless Steel | 1400 – 1450 | 2552 – 2642 |

| Tin | 232 | 449 |

| Titanium | 1668 | 3034 |

| Tungsten | 3422 | 6192 |

| Zinc | 419 | 786 |

| Silver | 961 | 1763 |

| Gold | 1064 | 1947 |

Understanding alloy ranges is essential. For instance, 6061 aluminum melting temperature varies due to magnesium and silicon content. Likewise, what’s the melting point of brass can change based on zinc ratio—critical when ordering custom lathed or pressed components.

What Determines a Metal’s Melting Point?

Atomic Bonding and Crystal Structure

The nature of metallic bonds and the atomic packing structure largely determine melting thresholds. Dense lattice arrangements and stronger bonds raise melting resistance. For instance, what is the melting point of tungsten (3422°C) is explained by its strong bond energy and atomic density.

This influences supplier selection. A vendor claiming heat-resistant “steel parts” must specify grade—since what temperature does steel melt at (~1400–1500°C) varies by carbon content and alloy additives.

Alloy Composition and Purity

Alloys like stainless steel or bronze melt over a range. This impacts not only how they’re machined but also how they behave in thermal testing. The bronze melting point, for example, may vary from 913 to 940°C depending on tin content.

Buyers concerned with part consistency should confirm certificates of composition. Especially when procuring cast iron components, be aware that what is the melting point for cast iron depends on carbon-silicon ratios and may influence thermal cracking behavior.

Environmental Conditions and Fabrication Method

Actual melting behavior can shift based on pressure, surface coatings, and forming history. High-altitude performance or vacuum-sealed applications can lower observed melting points slightly.

In processes like selective laser melting or electron beam melting, precision thermal thresholds must be controlled to avoid distortion or incomplete fusion. For parts designed for these methods, confirm the supplier’s equipment accuracy and familiarity with material-specific melt points.

Applications Based on Melting Ranges

Some procurement projects call for low-melting materials like indium or tin, where ease of joining is prioritized. If you’re sourcing parts for electronics, what is the melting point of tin (232°C) or what temperature does lead melt (327°C) becomes especially relevant in solder selection.

Conversely, applications involving jet engine housings or industrial furnaces may require how do you melt tungsten-level specifications. Tungsten’s extreme melting point demands high-energy furnaces and experience in carbide tooling.

Understanding these extreme ranges can help sourcing managers prequalify vendors for temperature-sensitive parts. It also reduces the risk of misquotes or overlooked specifications during RFQ planning.

From high-performance aerospace components to budget-conscious indoor fixtures, aligning application with the appropriate melting range streamlines your supplier negotiations and material approval process.

How Melting Point Influences Fabrication, Testing, and Risk Control

Compatibility with Metalworking Processes

When sourcing precision parts, it’s vital to match material melt behavior with the production method. For example, if your design requires deep-forming operations, low-melting alloys may deform or split.

For laser cutting, knowing what temperature melts aluminum helps ensure tooling and speed settings prevent edge oxidation or melting. And when brazing or welding copper or silver parts, control over what’s the melting point of silver (961°C) determines joint strength and finish.

Field Failures: When Materials Don’t Perform

We’ve seen real-world failures where enclosures made from zinc alloys warped during summer storage in containers. Understanding what temperature does metal melt at—and applying a safety margin—helps buyers avoid warranty claims.

In energy or outdoor sectors, high UV exposure or fluctuating ambient temperatures create conditions where material stress approaches the melt range. For solar brackets or outdoor kiosks, choosing stainless steel or titanium can ensure long-term performance.

Strategic Material Planning in Global RFQs

Knowing at what temperature does brass melt or what temperature does titanium melt allows teams to negotiate smarter with suppliers. It supports decisions around sourcing regions, coating needs, and even packaging (e.g., temperature-controlled shipping).

At YISHANG, we advise clients during RFQ planning to include thermal specs in drawings and conduct pre-shipment testing for high-risk components. This ensures dimensional integrity even after ocean freight.

Frequently Asked Questions

1. What temperature does metal melt? Depends on the type. Tin: 232°C, Aluminum: ~660°C, Steel: ~1450°C, Tungsten: 3422°C.

2. What is the melting point of aluminum (6061)? The 6061 aluminum melting point ranges from 582–652°C due to its alloying content.

3. What is the melting point of copper? 1085°C. Known for excellent conductivity and moderate thermal resistance.

4. What temperature does brass melt? Brass melts between 930–940°C. Always check with the supplier for exact composition.

5. What is the melting point of silver and gold? Silver: 961°C. Gold: 1064°C. Both are used in electronics and decorative applications.

6. How does melting point affect shipping and packaging? Low-melting metals may deform in hot containers. Use material data to select proper packaging and suppliers.

7. What is selective laser melting? An additive manufacturing process using lasers to melt and fuse metal powders layer by layer.

8. Can YISHANG help me choose the right metal for high-heat applications? Yes. Our team provides material guidance tailored to your use case and destination climate.

Conclusion

For wholesale buyers and international project managers, metal melting points are more than theoretical—they’re operational boundaries. They shape production specs, supplier qualification, logistics choices, and field performance.

From understanding what temperature does aluminum melt at to planning for high-temperature applications with what is the melting point of titanium, this knowledge streamlines sourcing decisions and protects investment.

Looking for heat-resistant sheet metal parts? YISHANG supports OEM/ODM sourcing with technical guidance and precision fabrication.

Request a quote now—we’ll help you build heat-tolerant solutions that last.