Making the Right 6061 Temper Choice: Minimize Risks, Maximize Reliability

For global buyers sourcing aluminum parts or custom-fabricated components, the choice of 6061 aluminum temper is not just a technical note—it directly impacts supply chain reliability, machining stability, and final part performance. At YISHANG, after working with hundreds of OEM clients in 50+ countries, one fact is clear: choosing the wrong temper often leads to scrap, delays, or unexpected failures after assembly.

6061 aluminum, or aluminum alloy 6061, offers a strong combination of strength, machinability, and corrosion resistance that commodity buyers find attractive. But within this alloy, each temper (T6, T651, T4, O, etc.) reflects a specific heat treatment method. These conditions define the metal’s behavior during forming, welding, and CNC machining—and ultimately how well it suits your production environment. In this guide, we provide actionable insights backed by global datasets to support your aluminum selection decisions with clarity.

Section 1|Why Temper Matters for Supply Chain and Production

Understanding 6061 temper codes is more than reading datasheets. Each temper (T6, T651, T4, O, etc.) represents a unique heat treatment history that determines forming, machining, and welding behavior—and whether your project runs smoothly or suffers costly setbacks.

6061 Temper Codes and Real-World Impacts

The temper of 6061 aluminum refers to its mechanical and thermal processing history. For example:

T6: Solution heat-treated and artificially aged for maximum strength.

T651: Same as T6 but stress-relieved by stretching, ensuring machining stability.

T4: Solution-treated and naturally aged. Better fit for forming.

O: Fully annealed for softness, often used for deep drawing.

Heat Treatment Processes and Fabrication Fit

Heat treatment plays a crucial role in how al-6061 performs on the shop floor. For example, a customer manufacturing formed LED housings in Canada shifted from T6 to T4 material to prevent cracking, then used post-forming aging to regain strength. This reduced scrap by 27% and allowed faster tooling changeovers.

In Mexico, another buyer supplying vending machine frames improved yield by 34% after switching from 6061-T6 to T4 for welded parts. These experiences highlight that selecting the right temper is as much about practical results as about datasheet values.

Section 2|Mechanical Properties and Fabrication Impact of Each Temper

From yield strength to elongation, every temper variation shifts how 6061 aluminum responds in real production. This section breaks down tensile performance, machinability, and coating compatibility—helping you link technical data with actual shop-floor outcomes.

Mechanical Properties You Can Depend On

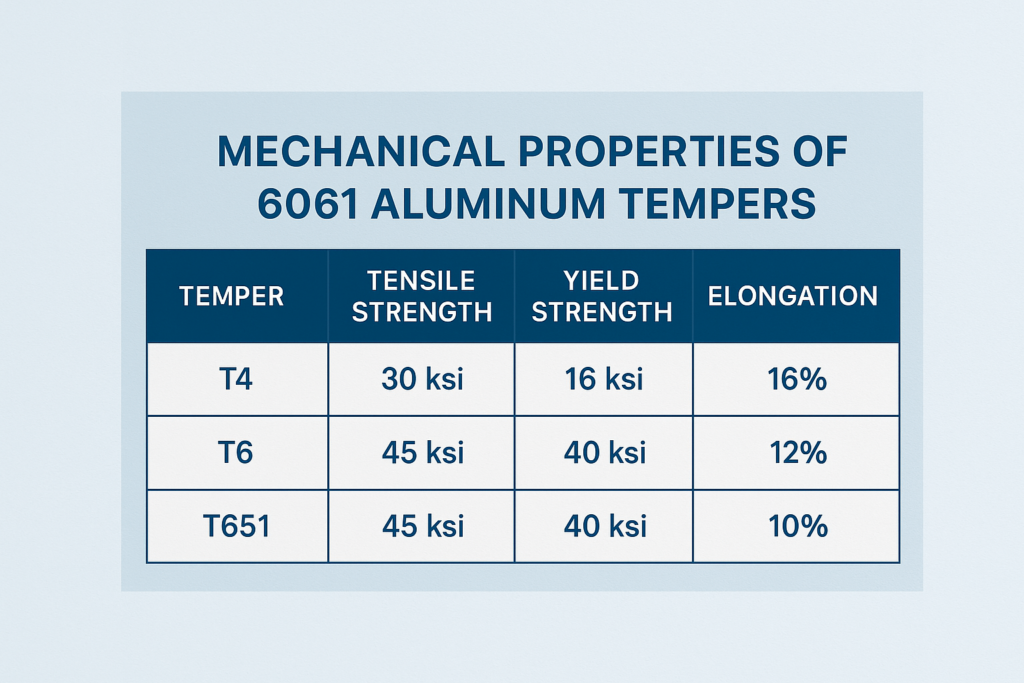

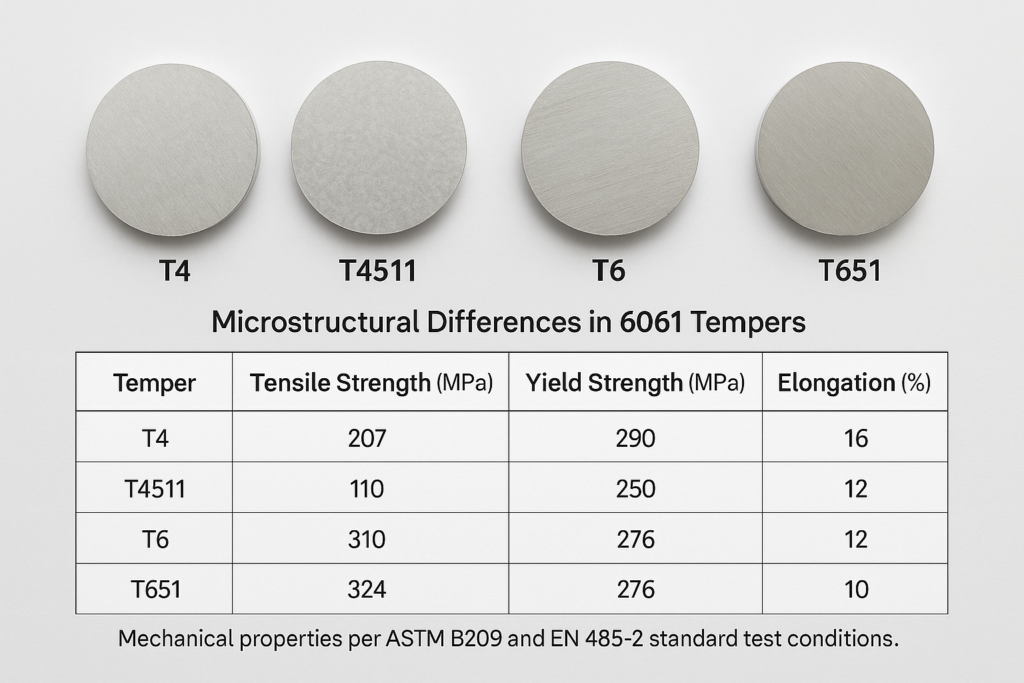

6061 aluminum hardness, ductility, and tensile strength vary by temper. Here’s a simplified comparison:

| Temper | Yield Strength (MPa) | Elongation (%) | Typical Use |

|---|---|---|---|

| T6 | ~276 | 8–10 | Machined or load-bearing parts |

| T651 | ~276 | 8–10 | CNC parts needing dimensional stability |

| T4 | ~145 | 16–18 | Formed or welded parts |

| O | ~55 | 25–30 | Deep-drawn or hydroformed components |

While T6, T651, T4, and O tempers are the most widely used, buyers may also come across less common designations:

F (As-Fabricated): Supplied without special heat treatment. Properties can vary, but it is sometimes used in low-cost or non-critical applications.

H (Strain-Hardened): Produced through mechanical working rather than heat treatment. Rare for 6061 but worth noting in certain regional supply chains.

W (Solution Heat-Treated, Unstable): A temporary temper condition that is rarely shipped but occasionally mentioned in mill certifications.

Even though these are less frequently used, awareness can prevent miscommunication when reviewing mill test certificates (MTCs) or supplier datasheets.

Stability, Stress Relief, and Machining Repeatability

Procurement teams sourcing for high-precision industries like aerospace or electronics should understand how stress relief affects tolerance control. We’ve supported multiple clients shifting from 6061-T6 to 6061-T651 to eliminate warping in critical CNC runs. The improvement in dimensional stability alone can justify a slightly higher per-kg cost.

If you’re machining parts over 200mm in length, choosing between 6061-T6 vs 6061-T651 could mean the difference between consistent first-pass yield and repeat rework.

Surface Behavior and Coating Compatibility

6061 aluminum’s melting temperature (~582–652°C) allows for anodizing and powder coating at industrial scale. However, temper affects not only appearance but also durability.

For example, anodizing T6 typically delivers better cosmetic results than T4 or O. One solar equipment buyer found anodizing on T6 parts led to fewer rejects due to color variation. In marine applications, where salt exposure is constant, proper anodizing post-processing and sealing are more impactful than switching to 7075 or 5052—although 5052 vs 6061 remains a valid corrosion performance debate.

Section 3|Practical Temper Strategies for Welding, Machining, and Forming

No single temper works for every process. Here we compare real-world cases of T6, T651, T4, and O in welding, bending, and CNC machining—showing how the right choice improves yield, extends tool life, and prevents rework.

Forming, Welding, and Machining Behavior

Global procurement leaders often ask: “Can we simplify our temper strategy across different processes?” Unfortunately, no one-size-fits-all answer exists. For instance:

T6 is great for machining but prone to cracking in forming or welding unless pre-heated.

T4 offers excellent formability and weldability but may need aging afterward.

T651 gives better chip control and avoids post-machining flatness issues.

In one project involving vending machine components, YISHANG replaced a client’s original T6 spec with T4 + post-aging, cutting forming defect rates by 34%.

Batch Yield, Tool Life, and Process Repeatability

If you’re managing high-volume production, selecting a temper that reduces tooling wear and supports consistent outputs is key. Using 6061-T4 over T6 in deep bending applications can extend tool life by 15–20%, as confirmed in our forming test beds.

CNC operators also report better surface finish with T651 than with standard T6, especially on larger surfaces. Our tests on al 6061 T6 vs T651 in 400mm x 600mm panel routing show 2.4x less flatness deviation with T651.

To simplify decision-making, here’s a practical guide to choosing the right 6061 aluminum temper based on common production needs:

CNC machining with tight tolerances → T651

Load-bearing strength at lower cost → T6

Welding or forming before aging → T4

Deep drawing or maximum ductility → O

Surface finish priority (e.g., anodizing) → T6

Using this checklist during supplier communication helps reduce the risk of sourcing mismatches and downstream production issues.

Section 4|Total Cost, Sourcing Feasibility, and Global Supply

Price per kg is only part of the story. Lead time, machining rejects, and regional availability also affect true project cost. This section explains how to balance temper choice with procurement realities, from bulk orders to JIT shipping.

Why Price per KG Can Be Misleading

Sourcing by material cost alone risks hidden inefficiencies. While T6 may be cheaper upfront, if machining rejects increase due to distortion or if your welding process requires multiple passes, your real cost-per-part escalates quickly.

We’ve observed that switching to T651 for CNC-intensive runs can reduce rework labor by up to 25%. Similarly, using T4 in welded enclosures prevents time-consuming post-weld heat treatments.

Also consider that aluminum 6061 material properties vary slightly by mill origin. Always request mill test certificates (MTCs) for high-reliability parts.

Availability, Lead Time, and Logistics Considerations

T6 and T4 tempers are generally widely available. However, T651 or 6061-T6 aluminum block stock in large dimensions may require special orders with extended lead times.

YISHANG supports clients by stocking common gauges of AL6061 in both T6 and T651 tempers. For bulk orders, we also offer MOQ flexibility, prototyping support, bonded stock supply, and JIT shipping to streamline your global procurement.

6061 aluminum tempers are defined consistently across international standards, but naming conventions can differ:

ASTM B209 (United States): Uses designations such as 6061-T6, 6061-T651.

EN 573 / EN 485 (Europe): Aligns with ASTM but may list additional mechanical property ranges.

JIS H4000 (Japan): Includes comparable tempers but sometimes references them with localized notations.

When sourcing across regions, confirm with suppliers which standard is applied to avoid confusion over mechanical property guarantees.

Contact Us|Get Expert Temper Recommendations from YISHANG

Need guidance on the right 6061 aluminum temper for your project? Contact our technical team to get sourcing advice, prototyping support, and global supply options tailored to your application.