When Old Techniques Win Modern Business

In today’s procurement landscape, B2B buyers aren’t just chasing innovation—they’re prioritizing resilience, cost control, and production flexibility. Sand casting, despite its traditional roots, checks all these boxes. It’s particularly valuable when buyers need mid-volume production, lower tooling costs, and rapid development cycles without compromising mechanical strength.

Take a recent case at YISHANG: an energy equipment buyer in Germany needed 1,500 custom housings within 40 days. Permanent mold methods didn’t align with their cost or timeline. By shifting to sand casting, tooling cost dropped by 75%, and production began within two weeks of approval. The result? On-time delivery without escalated unit cost.

This guide breaks down why sand casting continues to serve global sourcing needs and how it can fit seamlessly into a modern procurement strategy.

Sand Casting: Beyond the Basics

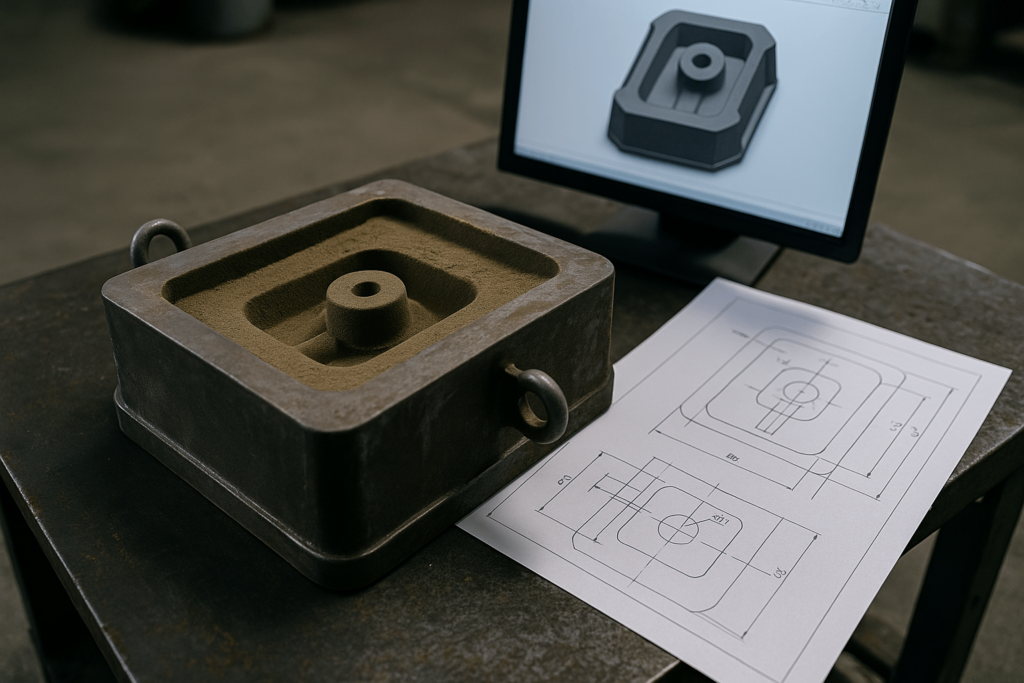

For many procurement specialists, the appeal of sand casting lies not in its simplicity, but in how it adapts. Behind the sand mold is a controlled production system: optimized gating, metal flow simulation, and digitally validated designs.

At YISHANG, we apply vacuum-assisted molding and resin-sand hybrids to support tolerances as tight as ±0.5 mm. This enables greater complexity while reducing the machining burden. Combined with in-house CNC capabilities, buyers receive parts that meet dimensional specs from day one.

This isn’t manual work—it’s a smart, scalable process that supports diverse B2B manufacturing needs across industries. That’s one of the main benefits of sand casting often overlooked.

Why Procurement Teams Choose Sand Casting

When facing demand fluctuation or custom part variants, locking capital into expensive permanent molds becomes risky. Wondering if your current production volume justifies permanent tooling? Sand casting offers a way to adapt without penalty. Compared to die casting or forging, tooling costs are lower—typically $3K to $5K—and changes are less disruptive.

For new product lines, regional variants, or pilot production, this method enables faster time-to-market. In our client base, 60% of mid-volume orders use sand casting specifically for this reason. It’s also aligned with lean manufacturing, where flexibility outweighs pure unit cost at scale.

One of the key advantages of sand casting in sourcing is the ability to iterate quickly with minimal waste.

The Sand Casting Process: What Buyers Should Know

Buyers don’t need to master metallurgy—but understanding how quality is built into each phase helps assess supplier capability:

Pattern Development: Based on CAD data. Optimized for draft angles and parting lines to minimize defects.

Molding: Sand composition and compression directly affect dimensional stability. YISHANG uses daily batch validation.

Pouring & Cooling: Controlled metal temperatures and gating systems ensure full cavity fill.

Post-Casting: Includes knockout, trimming, shot blasting, and CMM inspection.

We also conduct mold flow simulations for all new parts, identifying potential hot spots before the first pour. For procurement teams, this minimizes uncertainty.

Material Options for Global Compliance

Sand casting supports diverse alloys: aluminum, ductile iron, stainless steel (304/316), brass, and more. Each material serves different industries—whether high thermal conductivity for energy or corrosion resistance for marine applications.

YISHANG’s material sourcing complies with ISO 9001 and RoHS. For dimensional accuracy and tolerance grades, we follow ISO 8062 CT10 standards unless otherwise specified. Upon request, we provide full mill certs and third-party inspection records. Our clients in Europe and North America often require ASTM or EN standards, which we accommodate without cost-driving reformulation.

Procurement decisions around material choice often come down to availability, machinability, and compliance—not just specs on paper.

Design Input That Reduces Rework

We help purchasing teams reduce risk and cost by advising on design for manufacturability (DFM):

Avoiding non-uniform walls that cause sink marks.

Adding fillets instead of sharp corners to improve metal flow.

Recommending machining allowances that fit the final tolerance window.

These inputs reduce rework by 20–30% on average. The advantages of sand casting include this built-in flexibility—design changes don’t require full retooling.

Our engineers routinely suggest changes that bring parts within tolerance without driving up cost or extending timelines.

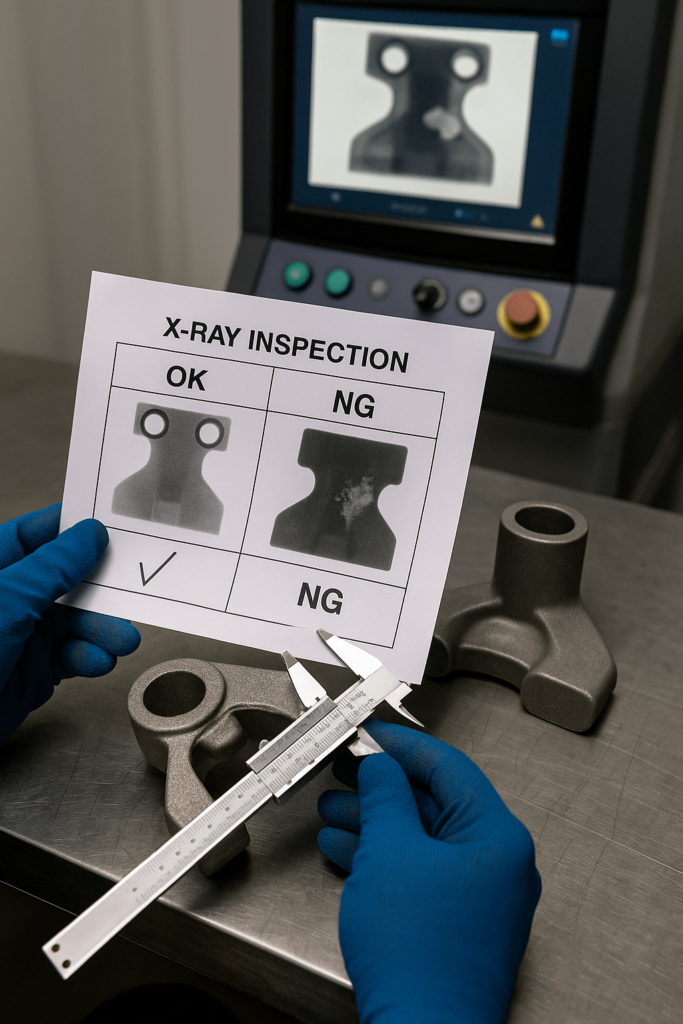

Quality Control from Sand Upward

Poor sand quality leads to porosity, shrinkage, or dimensional drift. We run daily tests on grain size, green compression, moisture, and binder ratio. For aerospace or hydraulic parts, we switch to sodium silicate or resin-bonded sand.

NDT, X-ray testing, and 3D scanning are available per spec. YISHANG provides buyers with quality control documentation per batch, including defect rate data and corrective action tracking.

This allows wholesale procurement teams to maintain traceability and predict defect trends across POs.

Applications That Match B2B Demand

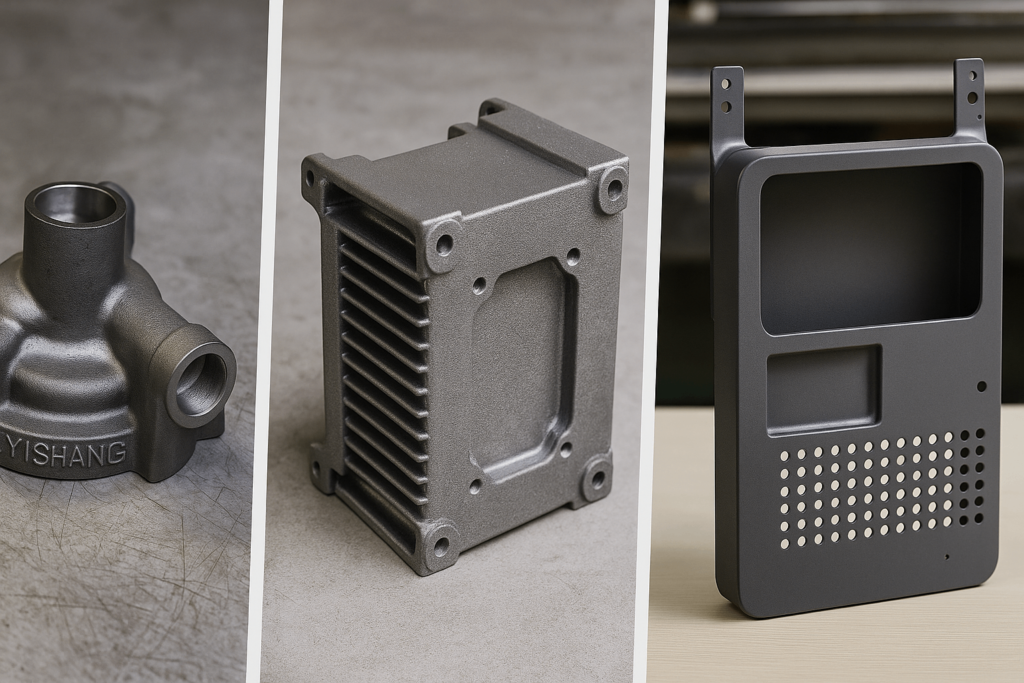

YISHANG supplies sand cast parts for:

Automotive: Suspension brackets, engine housings, pump covers.

Energy: Transformer frames, heat sink bases.

Machinery: Bearing housings, structural joints.

Retail Equipment: Custom vending enclosures, kiosk arms.

We support clients from prototyping to high-volume repeat orders. Our standard lead times range from 15 to 35 days, depending on part size and finishing needs.

We also offer full packaging and labeling services to meet distributor and OEM specs.

Procurement Pitfalls to Avoid

Not all sand casting suppliers offer the same consistency. Some common flags:

No digital simulation of mold flow = higher defect risk.

External machining vendors = fragmented quality control.

Irregular sand reclamation = dimensional inconsistency.

At YISHANG, all machining is in-house. We reclaim and test sand on every shift. And we run real-time MES systems to ensure traceability across every PO.

When choosing suppliers, these differences impact not just price—but customer returns, warranty rates, and brand reputation.

How YISHANG Adds Value to Sand Casting

Trusted by clients in over 50 countries, YISHANG integrates engineering expertise with export-ready fulfillment. Our global sourcing clients—from mid-sized OEMs to industrial distributors—value our ability to balance flexibility and quality while maintaining lead time discipline.

We’ve embedded digital tools into every step:

CAD-integrated mold design with simulation.

In-house 3D printing of patterns for small batch precision.

Real-time ERP and quality tracking.

This helps our clients reduce TCO—not just unit price—by minimizing rework, delays, and coordination costs. Our team works directly with your sourcing and design staff to close gaps before production starts.

This is how we define the benefits of sand casting in a B2B sourcing context.

Final Word: Procurement-Driven Flexibility

Sand casting is no longer just for legacy parts—it’s a tool for adaptive, responsive sourcing. When your business needs to move fast, stay lean, and maintain high reliability, sand casting may offer the ideal mix.

YISHANG delivers not just components, but supply confidence. Let us help you solve your next metal sourcing challenge with process expertise and global delivery readiness. Whether for customized subassemblies, regional product lines, or first-batch launches, sand casting remains a sourcing asset—when done right.

Let’s explore how your current project could benefit from smart sand casting—starting with a free design and manufacturability review.

Ready to start a project? Contact our team today for a quote or technical review.