Sheet metal issues remain one of the top causes of missed deadlines in B2B manufacturing supply chains. As a senior project engineer, I’ve seen how the success of a product launch often depends on a single component. The critical moments that impact lead time, cost, and quality usually occur long before production begins—in the design phase.

Take, for example, a high-density server chassis we developed for a data center client. The first batch of parts looked perfect individually but failed during assembly due to tolerance stack-up issues. It wasn’t a production flaw—it was a design oversight. This experience taught us a crucial lesson: Perfect sheet metal parts are engineered, not just manufactured.

This guide reveals a proven system for achieving flawless, repeatable results in sheet metal fabrication—designed especially for wholesale procurement teams, project engineers, and buyers of high-volume, custom sheet metal components.

We’ll explore three essential phases:

The Blueprint Review: Solving 90% of problems at the design stage

The Proving Ground: Validating performance before volume

The Scale-Up: Maintaining quality and consistency in production

Stage 1: The Blueprint Review – Catching Issues Early

A well-executed design for manufacturability (DFM) review prevents most downstream issues. For overseas wholesale buyers coordinating with a custom metal fabrication supplier, this early alignment is key.

Material Behavior and Selection

Designers often ask: “Why did my aluminum enclosure crack?” The answer often lies in choosing a material without fully understanding its formability, yield strength, and springback behavior.

For example, 5052-H32 aluminum bends easily compared to 6061-T6, which is stronger but brittle. Grain direction also plays a key role—bending along the grain increases cracking risk. Traceability through Mill Test Reports (MTRs) ensures consistency in wholesale sheet metal production—especially for regulated industries like medical and automotive.

| Material | Formability | Yield Strength (Typical) | Corrosion Resistance | Weldability | Common Applications |

|---|---|---|---|---|---|

| 304 Stainless Steel | Good | ~215 MPa | Excellent | Excellent | Medical devices, food equipment, appliances |

| 5052-H32 Aluminum | Excellent | ~193 MPa | Very Good | Good | Enclosures, chassis, tanks |

| 6061-T6 Aluminum | Fair | ~276 MPa | Good | Good | Structural parts, brackets |

| A36 Mild Steel | Very Good | ~250 MPa | Low (needs coating) | Excellent | Frames, racks, construction |

Accurate Bending Design

Dimensional issues often result from a lack of understanding of sheet metal bending physics. Use a minimum bend radius equal to or greater than the material thickness to avoid cracks. Calculate flat patterns using correct K-factor, bend allowance, and bend deduction. Avoid placing holes too close to bends and include bend reliefs to prevent tearing.

Managing Tolerance Stack-Up

Even when individual parts are within tolerance, assemblies can fail. This is known as tolerance stack-up. Using Geometric Dimensioning and Tolerancing (GD&T) to define form, position, and orientation can prevent cumulative errors in OEM sheet metal assemblies.

Stage 2: The Proving Ground – Physical Validation

Before committing to volume production, verifying manufacturability with a first article inspection (FAI) is critical. This step reduces risk and builds trust between wholesale buyers and suppliers.

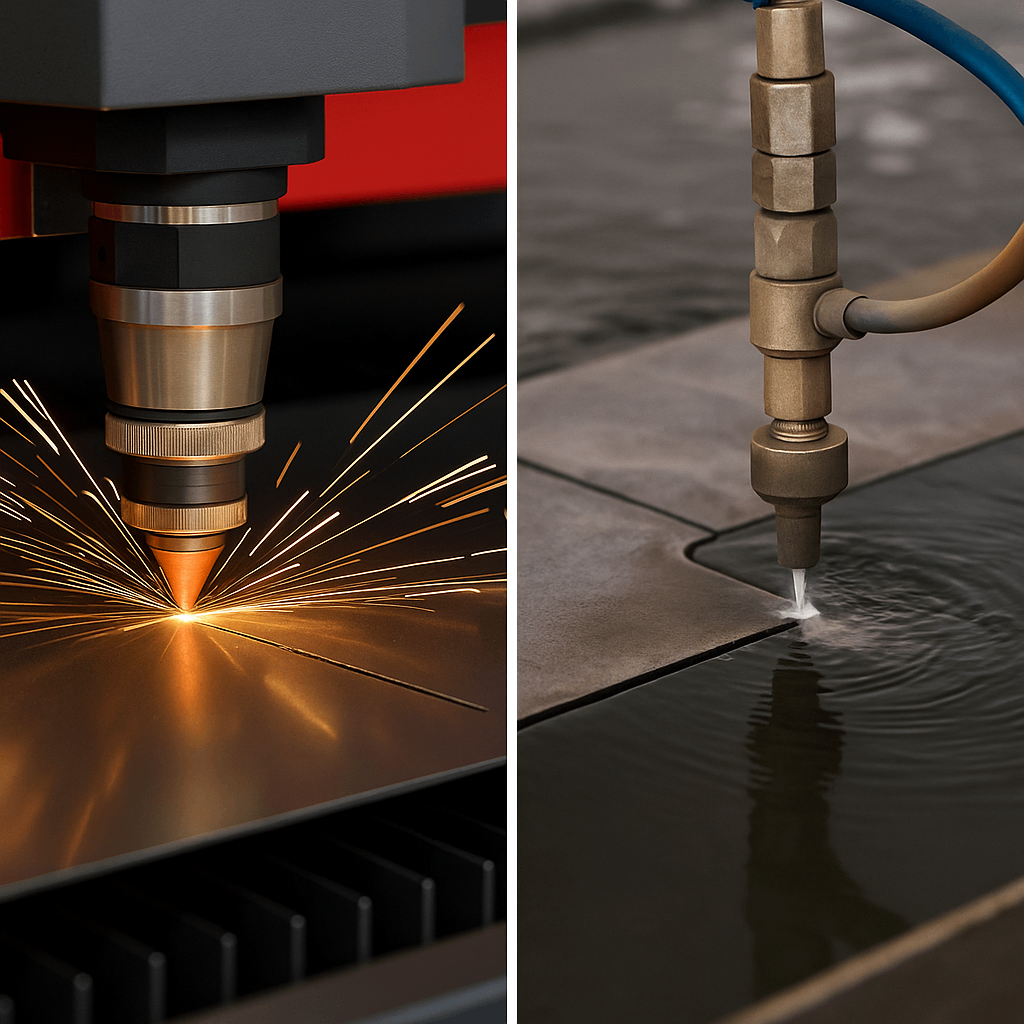

Cutting Methods and Edge Quality

Cutting methods impact precision and edge quality:

Stamping: Best for high-volume, low-complexity parts

Laser Cutting: Fast and accurate, but creates a heat-affected zone (HAZ)

Waterjet Cutting: Ideal for heat-sensitive materials

Deburring removes sharp edges and improves safety, assembly, and coating adhesion in downstream operations.

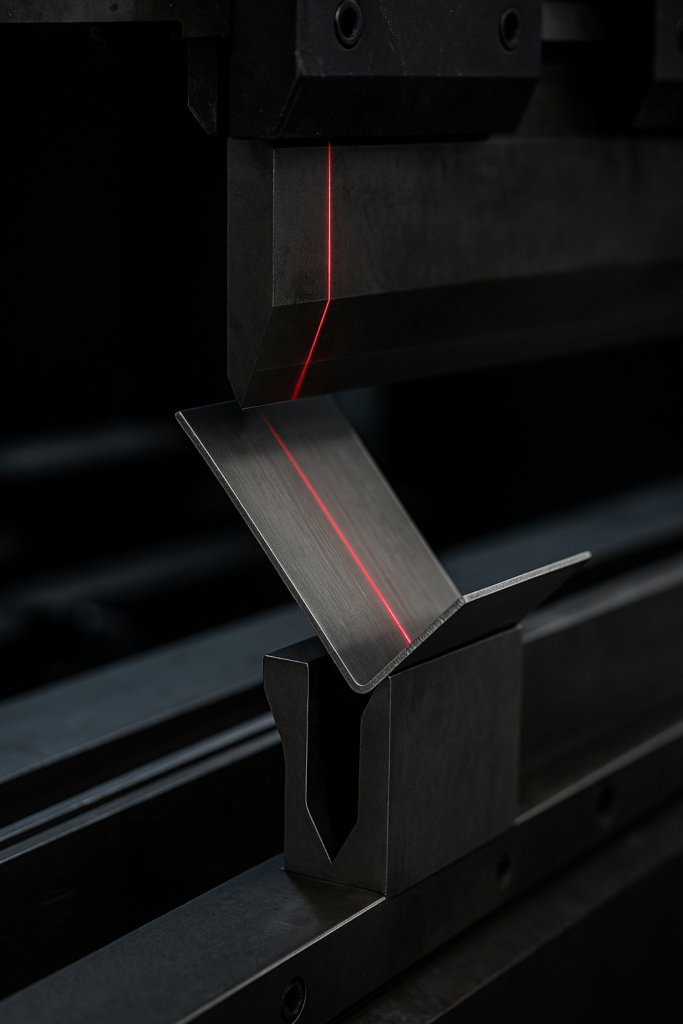

Forming Accuracy

To compensate for springback, techniques like over-bending, coining, or back bending can be used. CNC press brakes with laser guidance ensure repeatability for industrial sheet metal forming.

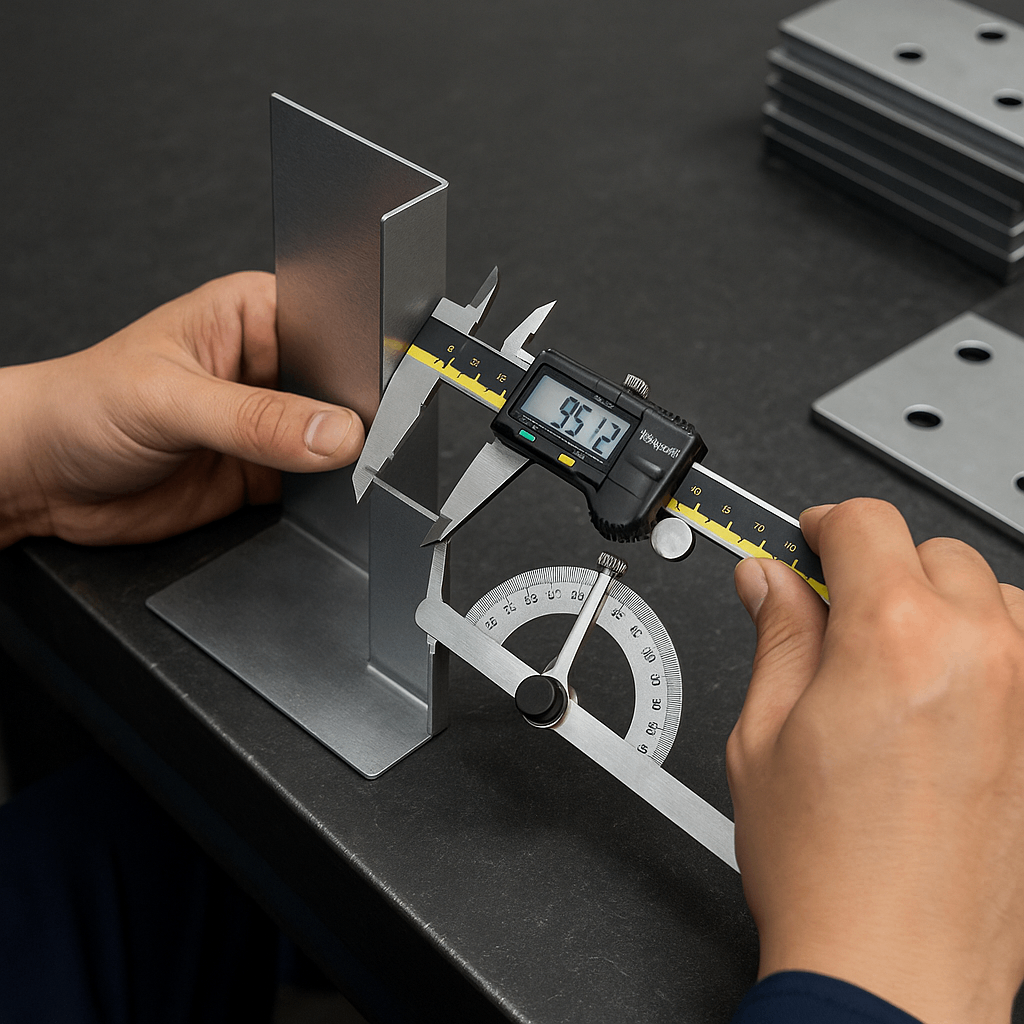

What a Good FAI Should Include

Ballooned drawings with key dimensions

Measured part data

MTRs for traceability

FAI builds mutual trust and sets the standard for ongoing production.

Stage 3: The Scale-Up – Achieving Repeatable Quality

Scaling production introduces new risks. Robust controls ensure consistency across thousands of units in a wholesale sheet metal manufacturing context.

Welding Without Distortion

Welding can warp parts without proper fixturing and sequence planning. Choose techniques based on project needs:

TIG: High precision

MIG: Faster throughput

Robotic Welding: Best for large-volume consistency

Real-Time Quality Checks (IPQC)

In-Process Quality Control (IPQC) embeds inspection into every stage. Operators verify bends using protractors or angle sensors. Statistical Process Control (SPC) flags deviations early and supports predictive improvements.

Using Feedback to Improve Long-Term

Top-tier suppliers use closed-loop systems to learn from defects. Root cause analysis leads to Corrective and Preventive Actions (CAPA)—a requirement for ISO 9001 compliance.

Final Thoughts: A Fabrication Partner Makes the Difference

Flawless sheet metal parts are the result of deliberate planning, smart design, and consistent execution. For procurement teams sourcing at scale, the right partner provides:

Early-stage DFM support

Full transparency during prototyping and FAI

Long-term quality control systems

With over 26 years of experience, exports to 50+ countries, and ISO 9001 certification, YISHANG Metal Products is your trusted partner for wholesale custom sheet metal fabrication.

FAQ: For Procurement and Engineering Teams

1. What’s the best way to form U-shaped sheet metal parts?

Use CNC press brakes and appropriate bend radii. For parallel legs, back bending ensures accuracy.

2. Why is FAI necessary?

It validates all critical specs before scaling production—saving time and cost.

3. How do I reduce springback?

Select suitable materials, adjust bend radii, and use techniques like coining or back bending.

4. What causes most sheet metal defects?

Incorrect radii, poor material selection, bad grain direction, or features too close to bends.

5. What should I look for in a supplier?

Choose a partner with ISO 9001 certification, engineering design support, and proven batch consistency—like YISHANG, a trusted OEM metal products supplier with decades of experience.

Submit your drawings today for a complimentary feasibility and manufacturability review by our senior engineers.

Submit your drawings today for a complimentary feasibility and manufacturability review by our senior engineers.