In high-volume metal parts procurement, success depends on cost-per-unit, production speed, and final product reliability. Even seemingly minor design details can cascade into major consequences for your budget and timeline.

Among these factors, the treatment of an edge—the transition between two surfaces—plays a crucial and often underestimated role. Choosing between a chamfer vs. fillet goes beyond aesthetics; it is a manufacturing decision that directly affects cost, strength, and assembly efficiency.

A raw, sharp corner invites problems. It represents a predetermined failure point where forces concentrate, often leading to costly field failures and warranty claims. Therefore, this guide outlines a practical framework for procurement managers and designers to consistently make cost-effective and reliable edge treatment decisions.

Part 1: The Core Decision – Understanding the Essential Difference

Unclear design communication leads to errors, waste, and delays. Clarifying terminology ensures your specifications are accurately translated from CAD model to final part.

1.1 The Engineer’s Lexicon: Precise Definitions

While often used interchangeably, these terms have distinct manufacturing meanings. Getting the chamfer meaning right is step one.

- A Chamfer is a flat, sloped, or beveled edge between two surfaces. Imagine it as “clipping” the corner. In the bevel vs chamfer debate, a chamfer is usually a 45-degree cut.

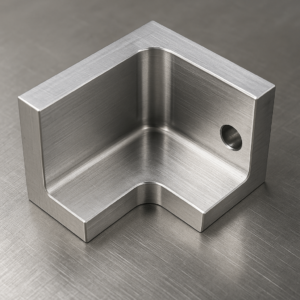

- A Fillet rounds an interior corner, creating a concave curve. This design improves durability by easing stress.

- A Round smooths an exterior corner, creating a convex curve. Often added for safety and comfort.

1.2 Strength and Reliability: Why a Fillet is a Load-Bearing Part’s Lifeline

Edges exist where forces concentrate. A sharp interior corner creates a stress concentration point, increasing failure risk.

For procurement managers, such a failure translates to lost reliability, damaged reputation, and costly returns. Choosing the right edge type safeguards against those risks.

A fillet radius distributes stress over a broader area. This smoother transition reduces peak stress and increases fatigue resistance.

That’s why fillets are critical in load-bearing components—especially those facing cyclic loads or harsh conditions. An appropriate radius becomes the hallmark of a well-engineered, durable design.

1.3 Assembly Efficiency: Why a Chamfer is the Key to Production Speed

Chamfers aren’t about strength—they’re about speed. An angled face helps guide parts like pins and bolts into position.

This advantage is crucial in automated lines or high-volume settings. A chamfered edge simplifies alignment, reducing insertion force and avoiding damage.

Don’t confuse this with a countersink. While both involve angles, a countersink is specific to accommodating screw heads.

In practice, chamfers increase throughput, reduce assembly labor, and enhance fitment. These savings accumulate quickly at scale.

Part 2: From Drawing to Quote – How Edge Choice Impacts Manufacturing Costs (DFM)

Design decisions become meaningful only when they affect production. The chamfer vs. fillet choice has surprisingly large implications for manufacturing cost. Understanding this connection supports smarter quoting.

2.1 CNC Machining: The High Cost of a Curve

Subtractive manufacturing highlights the cost differences.

- Chamfers: Easy and efficient. A chamfer can be cut in one pass using standard tools. Fewer tool changes and shorter cycles mean lower costs.

- Fillets/Rounds: More complex. Rounded edges require specific radius tools or time-consuming 3D paths using ball-nose end mills. These methods drive up machining time and cost.

If reducing cost is your priority, this insight matters. Fillets require more resources than chamfers—period.

2.2 Sheet Metal Fabrication: The Reality of Bending

In sheet metal, bend radii are often unavoidable. Making sharp corners may require more effort than rounding them.

Buyers should check the bend radius sheet metal specs for each material and thickness. These values are usually found in a bend radius chart (e.g., for aluminum).

Chamfers in sheet parts usually require a secondary step like milling or grinding. This adds cost and time, which must be considered during quoting.

2.3 Casting and Molding: A Complete Reversal of Logic

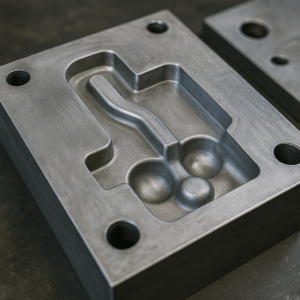

In formative processes, the logic flips. Fillets are not optional—they’re essential.

- Material Flow: Sharp corners block molten metal flow, creating defects. Fillets enable smoother paths and better fills.

- Tool Life & Ejection: Fillets prevent stress build-up, reducing warping and tool wear. Long-term, they also protect molds.

For casting, adding fillets improves quality and lowers tooling maintenance. Choosing a supplier like YISHANG, who understands this, makes a difference.

Part 3: The Buyer’s Handbook – How to Specify for Value and Avoid Costly Errors

How you call out edges says a lot about your engineering experience. Knowing when to specify—and when not to—can save time and money.

3.1 When to Dimension vs. Using a General Note

Many drawings are over-detailed, especially with non-critical edges. At YISHANG, we recommend using the general note: “BREAK ALL SHARP EDGES AND REMOVE ALL BURRS”.

This keeps drawings clean and flexible. It also lets fabricators choose the most efficient deburring method, streamlining production and preventing delays.

3.2 The High Cost of Tight Tolerances

Tolerances impact cost. Specifying tight tolerances (like ±0.05 mm) drives up inspection and machining time.

Only apply these tolerances when necessary. Use standard tolerances for cosmetic or safety features.

Well-written drawings—compliant with ASME Y14.5—differentiate between mission-critical and non-critical dimensions. This approach minimizes cost inflation.

3.3 A Critical Factor: Coating Adhesion and Corrosion

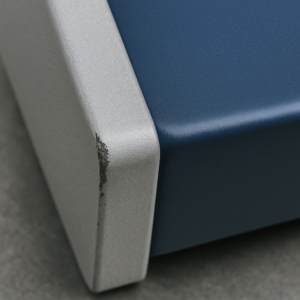

Sharp edges resist coatings. On a chamfer, paint pulls thin, increasing chipping and corrosion risk.

By contrast, rounds and fillets support even coverage. The improved coating thickness enhances protection, especially for outdoor or corrosive environments.

This difference is subtle but crucial. Surface prep affects finish quality, longevity, and warranty costs.

Part 4: Beyond Function – Identifying a High-End Supplier’s Capability

Some projects go beyond function. Surface transitions can influence product appeal, especially in visible or tactile parts.

4.1 From G1 to G2/G3: The Difference in Surface Quality

- G1 (Tangent Continuity): Basic. Reflections break at the junction.

- G2 (Curvature Continuity): Smooth. Light flows across the transition, ideal for visible parts.

- G3 (Torsional Continuity): Seamless. Demanded in luxury goods and automotive exteriors.

Achieving G2 or G3 continuity reflects advanced tooling and surfacing skills.

4.2 Relevance for High-Value Metal Products

Premium parts—from CNC-machined casings to display housings—require surface refinement. Suppliers who can deliver G2 or G3 finishes offer a competitive edge.

For clients in sectors like consumer electronics or medical devices, these details impact user perception and brand value.

Part 5: Quick Reference FAQ

Q1: When should I specify a fillet vs. a chamfer? Use a fillet for strength and fatigue life. Use a chamfer for easy assembly.

Q2: Which is cheaper to manufacture? In machining, chamfers are cheaper. In casting, fillets often reduce defects and tool wear.

Q3: Which prevents part failure better? A fillet, due to its ability to reduce stress concentration.

Q4: Are all chamfers 45 degrees? No. Other angles (e.g., 30°) are valid. Always define length and angle if non-standard.

Q5: Do I need to call out every edge? No. Use general notes for non-critical edges to reduce drawing clutter and costs.

Conclusion: The Edge as a Signature of a Quality Supplier

Edges may seem small, but they carry big consequences. Choosing between a chamfer and a fillet requires both theoretical and practical understanding.

A trusted supplier like YISHANG applies these principles in every project. We balance durability, efficiency, and cost to help you succeed.

Want help optimizing your next part drawing? Contact YISHANG for tailored support from seasoned fabrication professionals.