In materials science and component sourcing, clear classifications are essential for specification and procurement. We have metals—strong, conductive, and ductile. We have nonmetals—insulating and brittle. However, straddling the line between these two is a unique class of elements that defies simple categorization: the metalloids.

For engineers, OEM buyers, and industrial procurement managers, these “in-between” elements are not a mere curiosity; they are a source of immense technological and commercial value. Their unique blend of properties is the foundation for the entire semiconductor industry and is critical to advancements in performance alloys, infrared optics, and renewable energy systems. A deep understanding of their capabilities, limitations, and sourcing realities is key to making strategic material selection decisions in today’s competitive supply landscape.

Part 1: A Practical Definition for Material Specifiers

The term “metalloid” literally means “metal-like,” a name derived from their often lustrous appearance. However, for industrial applications, their physical and electrical behavior is far more important than their appearance.

They occupy a diagonal, stair-step region on the periodic table, forming a crucial boundary between the true metals and the nonmetals. The six core metalloids that are central to industrial and commercial applications are Boron (B), Silicon (Si), Germanium (Ge), Arsenic (As), Antimony (Sb), and Tellurium (Te).

For a buyer or engineer, their defining characteristics are best summarized by performance attributes:

- Appearance: Metallic luster.

- Mechanical Properties: Hard but brittle, a key factor that makes them unsuitable for standalone structural use.

- Conductivity: They are semiconductors, meaning their ability to conduct electricity is not fixed but can be precisely controlled—a property that is the bedrock of all modern electronics.

Part 2: The Engineering Advantage: Controlled Conductivity

The most critical property of metalloids from a commercial and engineering standpoint is their status as semiconductors. This is governed by their electronic structure, specifically a parameter known as the band gap.

In simple terms, the band gap is the energy required to get an electron to move freely and conduct electricity. In metals, this gap is nonexistent, so they always conduct. In insulators, the gap is massive, so they are non-conductive.

Metalloids possess a small, manageable band gap. This unique feature allows their conductivity to be toggled “on” or “off” with an external energy input, forming the basis of the transistors that power every digital device.

Doping: Engineering Material Performance at the Atomic Level

The true industrial power of metalloids is unlocked through doping—a highly controlled manufacturing process that introduces trace impurities to modify their electrical behavior for specific applications.

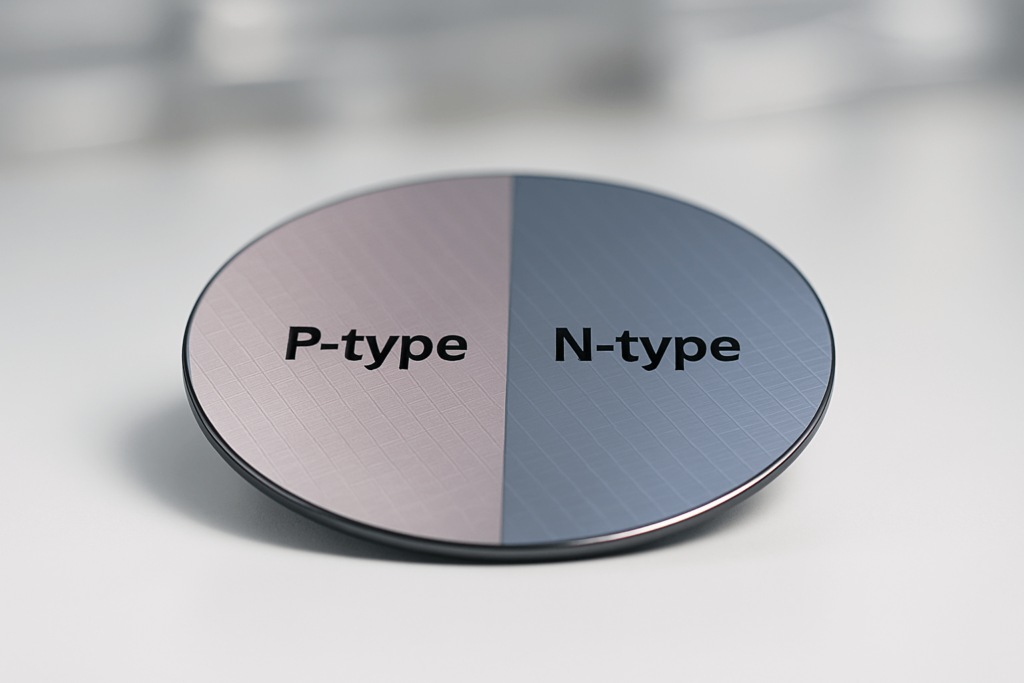

By adding elements with more valence electrons (such as phosphorus), we create N-type semiconductors with a surplus of free electrons, which act as negative charge carriers.

By adding elements with fewer valence electrons (such as boron), we create P-type semiconductors with an abundance of “holes” (electron vacancies) that act as positive charge carriers.

This atomic-level engineering allows for the creation of tailored semiconductor materials with precise electrical profiles, customized for high-speed microprocessors, photovoltaic cells, and power electronics.

Part 3: Metalloid Applications: A Procurement Perspective

Each metalloid offers a distinct value proposition. For a wholesale buyer, component specifier, or industrial sourcing specialist, understanding these nuances—including performance trade-offs, cost drivers, and supply chain volatility—is critical for selecting the right material for the intended environment.

🔹 Silicon (Si): The Undisputed Workhorse of Electronics

🔹 Germanium (Ge): The High-Performance Optics Specialist

🔹 Arsenic (As): High-Frequency and Specialized Medical Applications

🔹 Antimony (Sb): The Essential Alloying and Safety Agent

🔹 Tellurium (Te): Powering Solar and Next-Generation Data Storage

🔹 Boron (B): The Specialist in Hardness and Environmental Resistance

Part 4: The Future: Emerging Industrial Applications

The unique properties of metalloids continue to push frontiers in materials engineering.

Thermoelectrics: Converting Waste Heat to Power

Alloys like Bismuth Telluride (Bi₂Te₃) can convert heat gradients directly into electricity. These thermoelectric generators are being explored for waste heat recovery in vehicles and industrial plants.

Topological Insulators: A New Frontier in Electronics

Certain metalloid-based compounds are under study as topological insulators, which could lead to low-power electronics and new computing architectures.

Part 5: Making the Right Material Choice

Metalloids are not a monolith. Each brings unique commercial and technical value. From cost-effective silicon to strategic antimony sourcing, your selection should be guided by application demands, supply stability, and compliance needs.

At YISHANG, we bring over 26 years of metal product manufacturing expertise, including high-precision machining and component-level customization. Our experience in applying metalloid-integrated materials—whether in flame-retardant frames, heat-stable enclosures, or electronics housings—ensures your product specifications align with global standards.

If you’re sourcing advanced metal components, we’re here to help. Contact our engineering team for tailored solutions and procurement insights.

Frequently Asked Questions

- Q: Which elements are metalloids? A: The six most widely recognized metalloids with significant industrial use are Boron (B), Silicon (Si), Germanium (Ge), Arsenic (As), Antimony (Sb), and Tellurium (Te).

- Q: Why isn’t aluminum (Al) a metalloid? A: While adjacent on the periodic table, aluminum’s properties are overwhelmingly metallic. It is classified as a post-transition metal.

- Q: Are polonium (Po) and astatine (At) metalloids? A: This is debated. Polonium behaves more like a metal, while astatine is a highly radioactive nonmetal. Neither sees widespread use.

- Q: What is the most important industrial use of metalloids? A: The most impactful use is silicon as a semiconductor in electronics.