Introduction: The Foundation of Quality in Every Tire

For professionals in the automotive supply chain, performance is paramount. The grip of a tire on a wet road or the efficiency of an EV is not a matter of chance; it is the result of precision engineering. The origin of this performance lies in a critical piece of industrial tooling: the precision metal tire mold.

This article provides a technical deep-dive into the world of tire mold manufacturing. It explores key material and structural decisions, advanced fabrication processes, and emerging technologies that directly affect production efficiency, tooling lifespan, and the final quality of every tire produced—topics crucial for industrial buyers seeking long-term ROI and production consistency. Whether you are sourcing a custom tire mold supplier or exploring tire mold design optimization for EV applications, this guide is engineered to inform your procurement decisions.

Part 1: The Mold’s “DNA”: Strategic Choices in Structure and Material

The design of a tire mold is a calculated engineering decision. For a procurement professional, understanding these foundational choices is key to assessing a supplier’s capability to deliver tooling that ensures production efficiency, longevity, and the quality demanded by the market.

This is where metallurgy and mechanical engineering converge to set the stage for a high-performance, cost-effective manufacturing operation.

The Structural Debate: Segmented vs. Two-Piece Molds

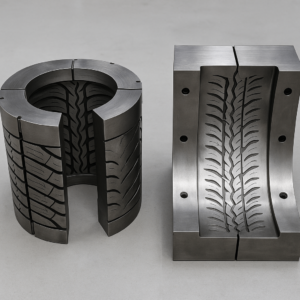

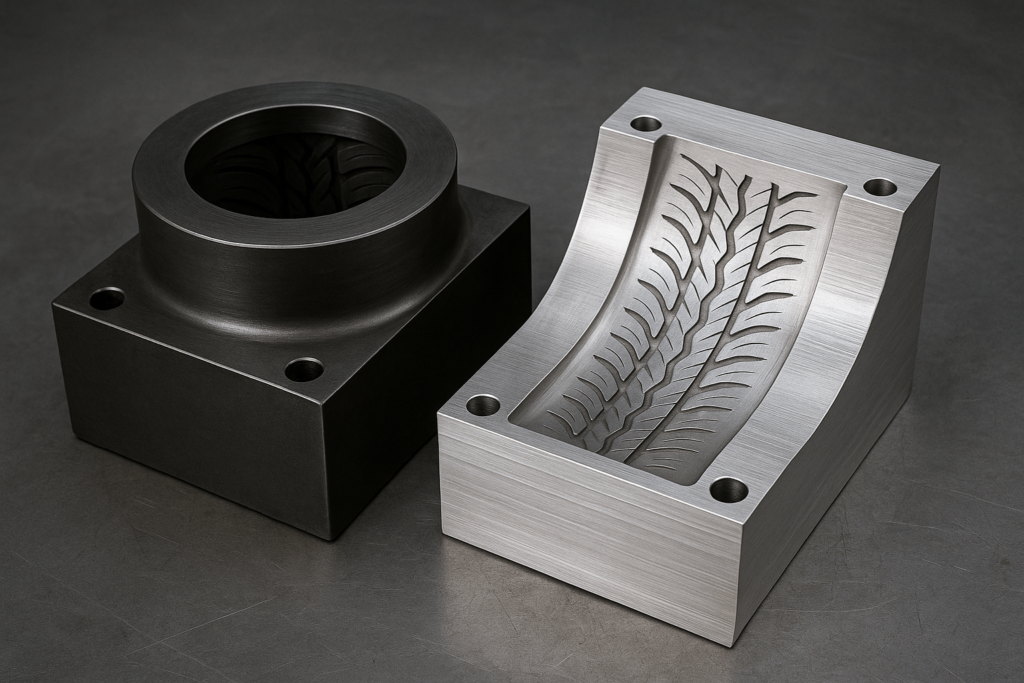

The architecture of a tire mold directly impacts production outcomes. The two dominant designs, segmented and two-piece (clamshell) molds, each offer distinct operational advantages tailored to specific tire applications.

Segmented molds are the standard for the modern passenger car tire market, accounting for approximately 63% of all molds in use. Comprising seven to ten concentric segments, this design is essential for creating the intricate tread patterns required for today’s high-performance tires.

From a quality control perspective, its most significant advantage is minimizing “green tire” movement during vulcanization. This results in superior tire uniformity and balance, directly reducing the potential for costly defects and improving end-product consistency.

Conversely, the two-piece mold remains the workhorse for heavy-duty applications where structural integrity is the primary concern. This robust design is favored for Truck and Bus Radial (TBR) and Off-The-Road (OTR) tires.

Its straightforward construction provides the immense strength needed to form the deep lugs and reinforced sidewalls of tires destined for commercial and industrial use, ensuring durability in the most demanding environments.

| Feature | Segmented Molds | Two-Piece (Clamshell) Molds |

|---|---|---|

| Design Principle | Multiple segments close radially | Two halves close vertically |

| Primary Application | Passenger Car Radial (PCR) Tires | Truck & Bus Radial (TBR), Off-The-Road (OTR) Tires |

| Tread Complexity | Very High; ideal for intricate designs | Limited; better for simpler, robust patterns |

| Tire Uniformity | Superior; minimizes tire movement for better balance | Lower; risk of uneven tread distribution in radials |

| Relative Cost | High (3-4 times more expensive) | Low |

| Market Share | ~63% | ~37% |

The Material Duel: Steel vs. Aluminum

The selection of metal for a tire mold is a strategic trade-off between tooling longevity and operational efficiency—a decision that directly impacts the total cost of ownership (TCO) and production throughput.

Steel molds, often crafted from high-grade tool steel, are the benchmark for durability. A steel mold can have a lifespan up to three times longer than its aluminum counterpart, capable of enduring millions of production cycles without significant degradation.

This resilience makes steel the unequivocal choice for high-volume, long-term manufacturing runs and for applications involving abrasive rubber compounds. Its rigidity ensures tight machining tolerances are maintained, guaranteeing quality and minimizing the need for frequent tool replacement.

In contrast, aluminum molds are prized for their impact on production speed. Aluminum’s exceptional thermal conductivity, nearly five times greater than that of steel, allows for significantly shorter vulcanization cycles.

In the high-volume world of PCR tire production, where cycle time is a critical KPI, this property directly translates to higher throughput and a lower cost per unit. While less durable, the gains in production speed often provide a faster return on investment (ROI), making aluminum the strategically superior choice for the mass market.

| Property | Steel Molds | Aluminum Molds |

| Thermal Conductivity | Low (~50 W/m-K) | Very High (~237 W/m-K) |

| Durability / Lifespan | Very High (Millions of cycles) | Lower (50,000 – 200,000 cycles) |

| Initial Tooling Cost | High | Low (2-3 times cheaper) |

| Cycle Time | Longer | Significantly Shorter |

| Wear Resistance | Excellent | Lower; more prone to damage |

| Primary Application | TBR, OTR, Long-life production | PCR, Prototyping, High-volume production |

Part 2: The Birth of a Mold: A Journey of Precision Metal “Cultivation”

The creation of a modern tire mold is a direct reflection of a supplier’s technical depth. It is a multi-stage journey where a block of raw metal is refined into a tool of extraordinary precision, blending advanced software simulation with the tangible limits of high-precision metalworking to produce tooling that guarantees quality and repeatability.

Step One: The “Dress Rehearsal” in a Virtual World

Before any physical manufacturing begins, the tire mold is perfected in a digital realm. This virtual pre-production phase is critical for minimizing the need for costly physical prototypes and accelerating the development timeline.

The journey begins with CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software. A detailed 3D model of the tire is created in CAD, defining every groove and detail. This digital blueprint is then fed into CAM software, which generates the precise toolpaths for the CNC machines.

The key to ensuring quality lies in Finite Element Analysis (FEA). A tire is a complex composite that expands and contracts under the heat and pressure of vulcanization. Consequently, the final cured tire shape often differs from the mold’s internal geometry.

FEA simulation allows engineers to predict these changes with incredible accuracy. By modeling these stresses, they can “reverse-engineer” the process, designing a mold shape that results in a tire of the perfect final dimensions. This predictive capability allows for mold shape optimization before any physical prototyping, a crucial factor in reducing development costs.

Step Two: The Physical World of Precision Sculpting

Once the digital design is perfected, the process moves to the workshop floor. A supplier’s mastery of these core manufacturing processes is a direct indicator of their ability to deliver high-quality, reliable tooling.

5-Axis CNC Machining is the cornerstone of modern mold making. Unlike traditional machines, a 5-axis machine can move a cutting tool across five distinct axes simultaneously. This capability is essential for creating the complex contours and intricate geometries of modern tread patterns in a single setup, ensuring the highest degree of accuracy and tight tolerances.

Electrical Discharge Machining (EDM), or die-sinking EDM, is the master of micro-geometry. This non-contact process uses electrical sparks from a shaped electrode to erode metal, allowing it to create features that are physically impossible for a rotating cutting tool to produce.

EDM is indispensable for manufacturing the thousands of fine, deep, and sharp-cornered sipes (the tiny slits in tread blocks) that are critical for a tire’s grip on wet or icy surfaces. The precision of EDM can reach tolerances as low as +/- 0.004 mm, making it a vital technology for defining a tire’s ultimate performance.

Precision Casting, often using the “lost-wax” method, provides a balance of complexity and cost-effectiveness, particularly for high-volume production. This method is excellent for producing the near-net shape of mold segments with numerous intricate patterns, significantly reducing the amount of subsequent machining required and making it a highly efficient choice for large production orders.

The Disruptor Arrives: How 3D Printing is Reshaping the Rules

The advent of additive manufacturing, or metal 3D printing, is fundamentally disrupting the traditional mold-making landscape. For procurement managers focused on innovation and supply chain agility, understanding this technology is key.

The primary application where 3D printing has become essential is in the creation of intricate 3D sipes. Traditional manufacturing methods struggle to produce the complex, interlocking internal geometries of modern 3D sipes. Additive manufacturing, by building the part layer by layer, can create these previously impossible designs with ease.

Industry leaders like Michelin now produce over one million such 3D-printed sipe inserts annually, unlocking a new generation of tire performance.

Furthermore, companies like NEXEN TIRE are leveraging 3D printing to produce entire prototype molds, achieving a dramatic lead time reduction from months to mere weeks and cutting development costs by over 50%.

While additive manufacturing is not yet positioned to replace casting and CNC for the bulk production of standard mold bodies, its role as a strategic enabler for innovation and complex component manufacturing is firmly established.

Part 3: Mold in Motion – From Tool to Tire

With the mold fabricated, the spotlight shifts to its real-world integration on the factory floor. This section focuses on how the tire mold performs in production, how it’s maintained, and how it ensures consistency across thousands—or millions—of vulcanization cycles. For tire mold buyers evaluating tooling ROI or searching for long-life CNC tire molds, understanding in-plant performance is critical.

The Vulcanization Interface

The mold is the silent executor of the tire design, translating digital and machined geometry into rubber reality. During vulcanization, the green tire is placed within the heated mold, inflated by an internal bladder, and held under both heat and pressure. This is where the mold’s performance truly defines the product.

Precision alignment of mold segments or clamshell halves ensures tread accuracy and sidewall clarity. Any mismatch, even within a tenth of a millimeter, can cause visual defects or tire imbalance, leading to waste and customer complaints.

In aluminum molds, the faster thermal response allows for quicker mold closing and opening cycles—directly impacting output per shift. Meanwhile, steel molds retain dimensional integrity even after repeated high-heat cycles, reducing the frequency of re-machining or replacement.

Modern facilities now employ smart molds equipped with embedded temperature sensors, RFID tags, and cycle counters. These enable real-time monitoring and predictive maintenance, reducing unexpected downtime and increasing yield.

Maintenance Matters: Extending Mold Life

Even the most robust mold needs a disciplined maintenance routine to deliver consistent product quality over time. Maintenance is not an afterthought—it is a strategic pillar of production stability.

Daily cleaning is crucial to remove rubber residue, mold release agents, and curing by-products. Laser cleaning systems are increasingly preferred for their non-contact approach and ability to clean micro-geometry without damaging the mold.

Periodic inspections using CMM (Coordinate Measuring Machines) allow for dimensional checks to verify that mold geometry remains within tolerance. This is especially critical for molds with high-cycle volumes, as minor deformations can lead to cumulative quality loss.

Many manufacturers now adopt a rotational maintenance strategy—cycling molds through active use, cooldown, and inspection stages to ensure thermal stability and even wear distribution. This approach enhances mold lifespan without disrupting production schedules.

Lifecycle Economics: ROI Beyond the Initial Cost

The mold’s cost is not limited to its purchase price. The total value lies in its throughput capacity, maintenance efficiency, and failure rate.

For example, although aluminum molds have shorter lifespans, their faster cycle time often leads to a lower cost-per-tire when used in high-throughput operations. Conversely, steel molds may offer a better ROI in long-run, abrasive rubber or off-road applications where durability is paramount.

When evaluating mold suppliers, buyers should ask for cost-per-10,000-units analysis rather than just mold unit price. This encourages transparency and helps align procurement decisions with long-term manufacturing KPIs.

Part 4: Futureproofing – Tire Molds in the Age of EVs and Digital Twins

Tire design is evolving quickly due to electric vehicles (EVs), sustainability regulations, and digitalization of manufacturing. Tire molds are not immune to these shifts—in fact, they’re at the epicenter.

The EV Challenge: Torque, Weight, and Silence

Electric vehicles pose unique challenges: increased vehicle weight due to battery packs, near-instant torque delivery that accelerates tread wear, and customer expectations of a quieter cabin.

These trends demand new tread patterns, deeper sipes, and optimized contact patches. Consequently, tire molds must now enable higher complexity with tighter tolerances. 3D-printed sipe inserts are becoming standard, allowing designers to create novel geometries that balance grip and noise suppression.

Aluminum molds—with their lower thermal inertia—are ideal for EV tire production lines where shorter, more flexible batch runs are needed. This aligns with the current shift toward mass customization in tire offerings for varied EV models.

Digital Twin Integration

Tire molds are now part of the digital twin ecosystem—virtual replicas of the production environment that simulate and optimize physical processes in real time.

A digital twin of a tire mold can simulate heat transfer, deformation, and cycle timing, allowing for iterative improvements without physically touching the mold. This significantly reduces trial-and-error costs and compresses development timeframes.

For OEMs and Tier 1 suppliers, the ability to integrate mold data into the broader MES (Manufacturing Execution System) enables smarter planning, predictive maintenance, and quality traceability.

Towards Sustainability: The Eco-Conscious Mold

With tightening environmental regulations and increased ESG scrutiny, tire mold suppliers are also adapting.

Mold coatings are evolving to include non-toxic, low-friction surface treatments that reduce the need for chemical release agents. Some manufacturers are exploring recyclable aluminum alloys and hybrid mold materials to reduce carbon impact.

The move toward modular mold components—where worn sipe inserts or tread plates can be replaced without discarding the entire mold—is also gaining momentum. This enhances resource efficiency and lowers environmental burden.

Conclusion: Why Molds Matter More Than Ever

Tire molds are no longer static tools—they are smart, agile, and central to modern tire performance. For engineering and procurement teams, understanding the interplay between mold design, material, and manufacturing is vital to maximizing production efficiency and product differentiation.

As EV adoption accelerates and sustainability becomes a competitive metric, the ability to partner with tire mold manufacturers offering advanced capabilities—like 3D printing integration, data-enabled maintenance tracking, and lifecycle cost analysis—will define long-term success in this evolving global supply chain. Especially for those looking to source tire mold tooling for electric vehicles or implement digital twin tire mold systems, future-ready solutions are now a procurement priority.

Frequently Asked Questions (FAQ)

Q1: What’s the average lead time for a custom tire mold?

Lead times typically range from 4 to 10 weeks depending on mold complexity, size, and whether additive components or custom patterns are required.

Q2: Can 3D printing fully replace CNC or casting?

Not yet. 3D printing is ideal for complex sipe inserts and rapid prototyping but not yet cost-effective for bulk mold body production.

Q3: What affects the lifespan of a tire mold the most?

Key factors include the chosen material (steel vs. aluminum), thermal cycling rates, maintenance regularity, and production volume per batch.

Q4: What should I look for in a mold supplier?

Look for a vendor with proven CNC and EDM capabilities, FEA-backed mold design, and an understanding of EV-optimized tire tooling. If you’re seeking a tire mold manufacturer in China with OEM/ODM capabilities, also assess experience with 3D printed sipe inserts and smart mold data integration.

Q5: How do tire molds impact final tire performance?

Directly. Mold accuracy determines tread depth, uniformity, and sipe geometry, which translate into tire grip, wear life, balance, and noise control.

Ready to Source Tire Molds with Industrial Precision?

YISHANG offers OEM & ODM tire mold solutions backed by 26+ years of sheet metal and CNC expertise. From precision steel molds for TBR to high-throughput aluminum tooling for PCR and EV tires, our integrated services cover design support, rapid prototyping, fabrication, surface treatment, and global shipping.

📩 Contact our engineering team today for a custom consultation or quote.