Introduction: Beyond the Breaker Box – The Engineering of a Power Fortress

In any modern building, the electrical distribution panel serves as the central nervous system for power management. While often seen as a simple housing for circuit breakers, its true significance lies in its robust construction and adherence to stringent safety standards. From the perspective of a manufacturer like YISHANG, with 26+ years of experience in custom metal fabrication for global buyers, we see this component not as a box, but as a precision-engineered power fortress.

This guide is tailored for industry professionals and wholesale purchasers. We will move beyond basic definitions to provide a deep analysis of the panel’s construction, compliance certifications, procurement-ready component options, and technologies it houses, helping you make informed decisions for large-scale or project-based sourcing.

Part 1: Core Decryption – What Is a Distribution Panel?

At its most fundamental level, a distribution panel is the primary component of an electricity supply system. It serves as the central hub where the main power feed is divided into smaller, manageable, and individually protected subsidiary circuits.

This centralized design is a cornerstone of modern electrical safety, providing a single point of control for a building’s entire grid and aligning with global electrical design best practices.

To better navigate international markets, it’s important to understand the varying terminologies for this essential component:

- Circuit Breaker Panel / Breaker Box – Common in North America, associated with modern panels featuring resettable breakers.

- Fuse Box – The older version, using disposable fuses.

- Load Center – Typical for residential and light commercial use in North America.

- Consumer Unit (CU) – Standard term in the UK and Commonwealth regions.

- Service Panel – Denotes the main power entry point into a building.

No matter the label, the function remains consistent: robust circuit protection, load distribution, and safe power management.

Part 2: The Power Fortress – A Deep Dive Inside the Distribution Panel

To fully understand the engineering and fabrication standards of a distribution panel, especially for OEM and ODM orders, one must explore its internal structure. It is a carefully structured system where each element ensures long-term electrical safety and industrial reliability.

The Metal Enclosure: The First Line of Defense

The enclosure is more than a shell—it’s a protective fortress. For wholesale buyers, enclosure quality directly signals long-term field performance.

Usually made from sheet metal, its purpose is structural integrity, flame resistance, and protection against environmental exposure. Common materials include:

- Stainless Steel (304/316) – Corrosion-resistant, suitable for coastal or industrial zones.

- Aluminum – Lightweight, with excellent natural anti-corrosion properties.

- Carbon Steel – Durable and cost-efficient for indoor installations.

Manufacturing often includes:

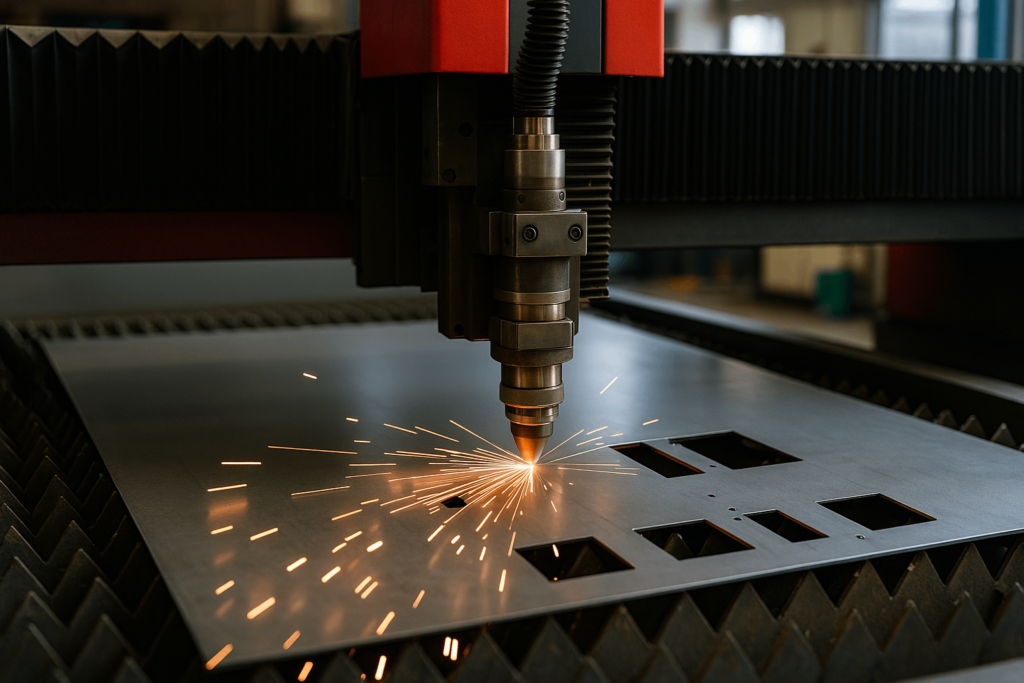

- CNC Laser Cutting or Turret Punching – For precision holes, breaker windows, and accurate panel design.

- Powder Coating Finish – Enhances corrosion resistance and visual quality; complies with ANSI/UL 1332.

- High-Grade Fasteners – Used in assembly for structural strength, vibration resistance, and longevity.

Designs may incorporate a “dead front” safety barrier, ensuring zero accidental contact with energized components.

YISHANG also supports the fabrication of OEM distribution panel enclosures using 304 stainless steel, powder-coated carbon steel, or outdoor-rated aluminum for harsh environments.

The Main Breaker, Busbars, and Terminal Bars

The main breaker governs incoming power, feeding it into busbars—rigid copper or aluminum conductors that distribute current.

- Copper Busbars – Preferred for their superior conductivity and lower thermal rise.

- Aluminum Busbars – More budget-friendly, commonly used in large-scale projects.

Neutral bars and ground bars finalize the circuit, providing safe return paths and grounding in line with regional codes.

Part 3: The Science of Safety – “Overload” vs. “Short Circuit”

A panel’s essential role is overcurrent protection. Understanding the difference between overload and short circuit is essential for technical specification and safety planning.

The Slow Burn: The Nature of an Overload

An overload occurs when a circuit is continuously overdrawn. The resulting heat degrades insulation and poses fire risks.

The Sudden Catastrophe: The Nature of a Short Circuit

A short circuit is abrupt and dangerous. Direct contact between live and neutral/ground conductors can release extreme energy within milliseconds.

Thermal-magnetic breakers mitigate both:

- A bimetallic strip deflects due to heat buildup (overload).

- An electromagnetic trip activates instantly under fault current (short circuit).

These dual-mechanism breakers are standard in modern panels and mandatory in many jurisdictions.

Part 4: Meet the Guardians – A Guide to Circuit Breaker Types

Specifying the correct circuit breaker types is a core responsibility during procurement. Each type suits different applications and regulatory conditions.

The Workhorses: Standard Breakers

- Single-Pole Breakers – Handle 120V loads; lighting, general receptacles.

- Double-Pole Breakers – For 240V circuits; HVAC, ovens, water heaters.

The Lifesavers: Ground Fault Circuit Interrupters (GFCIs)

GFCIs detect small leakage currents to ground and trip rapidly—typically within 25 milliseconds—to prevent electrocution.

The Firefighters: Arc-Fault Circuit Interrupters (AFCIs)

AFCIs identify dangerous arcing conditions. These breakers protect wiring and equipment from arc-induced fires.

The All-in-One: Dual-Function Breakers

Combine AFCI + GFCI in one unit, offering maximum protection for multi-function spaces.

| Breaker Type | Primary Protection | Voltage | Typical Amperage | Common Applications |

|---|---|---|---|---|

| Single-Pole | Overcurrent | 120V | 15A, 20A | Lighting circuits, receptacles. |

| Double-Pole | Overcurrent | 240V | 20A–60A | Air conditioners, ranges, EV charging. |

| GFCI | Ground Fault | 120V | 15A, 20A | Bathrooms, kitchens, outdoor outlets. |

| AFCI | Arc Fault | 120V | 15A, 20A | Bedrooms, family rooms, code-required zones. |

| Dual-Function | GFCI + AFCI | 120V | 15A, 20A | Laundry rooms, basements, combo spaces. |

Part 5: Key Considerations for Panel Lifespan and Replacement

Determining when to replace or upgrade a panel ensures continued safety and capacity for future expansion.

Common triggers include:

- Obsolete Units – Replace outdated fuse panels with modern breaker panels.

- Low Capacity – 100A or smaller panels may not meet modern energy needs.

- Visible Damage – Corrosion, moisture ingress, or scorch marks.

- Age – Units beyond 25–40 years typically require evaluation.

- Load Growth – Additions like EV chargers or solar PV systems demand reevaluation.

CRITICAL WARNING: The FPE & Zinsco Hazard

Federal Pacific (FPE) and Zinsco panels are linked to confirmed breaker failures and overheating. These models must be replaced regardless of visible condition.

Part 6: Compliance, Certification, and Installation Standards

Procurement teams must ensure enclosures meet recognized certifications. At YISHANG, we fabricate enclosures aligned with UL, NEMA, and regional standards to support cross-border sales.

UL and NEMA Ratings

- UL 50 / UL 508A – Confirm enclosure material, ingress protection, and thermal performance.

- NEMA 3R / 4 / 4X – Indicates protection from dust, water, corrosion (essential for outdoor or industrial installs).

Buyers in North America, Europe, and Southeast Asia often specify UL-certified or IP-rated custom sheet metal breaker boxes for energy storage, telecom, and vending system integration.

UL-listing improves acceptance in North America and global markets.

NEC Installation Code – 110.26

Minimum clearance zones:

- 36 inches front clearance

- 30 inches width working space

This ensures safety during maintenance or emergency shutoff.

Part 7: Future-Proofing for EVs, Solar, and Smart Infrastructure

Power panels now support more than legacy lighting. EV infrastructure, solar PV systems, and smart energy management are driving panel specification upgrades.

Sizing for Modern Loads

- 200A is the new base standard for residential and light commercial.

- EV chargers (Level 2) may draw 30A–60A.

- Solar systems create reverse flow (backfeeding), requiring careful busbar and breaker planning.

Always use licensed electricians for load calculations (per NEC 220.87 and 80% Rule).

Rise of the Smart Panel

Smart distribution panels bring intelligence and remote control to traditional boxes:

- Cloud-linked energy monitoring.

- Remote breaker shutoff.

- App-based load shedding and diagnostics.

YISHANG can also design custom smart breaker panel enclosures for integration with these systems, providing thermal management, cable routing, and IP/NEMA protection as required.

Conclusion: Partnering for a Safer, Smarter Energy Future

The distribution panel is no longer passive hardware—it is the backbone of every electrical infrastructure.

At YISHANG, we specialize in OEM/ODM electrical enclosures, supporting clients in over 50 countries across energy storage, EV charging, vending, telecom, automation, and industrial applications. Our services span from CNC cutting, powder coating, and welding, to design engineering, prototyping, and final packaging.

Request a Quote Now

YISHANG offers fast-response RFQ support with technical drawings, MOQ from 100 pcs, 7-day prototyping, and global delivery. Talk to our engineering team today and get specs and pricing within 24h.