A perfect design can be ruined by a single flawed weld. When a stainless steel joint fails prematurely due to corrosion or cracking, it’s rarely the welder’s fault alone—it’s a misunderstanding of the material itself.

This guide moves beyond basic techniques to explore the science behind the steel, turning common fabrication challenges into reliable, high-performance results that last. If your OEM components demand corrosion-resistant welds—especially in marine, food-grade, or structural applications—this stainless welding guide will help you get it right the first time.

Who This Guide Is For: This guide is written for the engineers, fabricators, quality managers, and procurement professionals who specify, work with, or inspect welded stainless steel components and are seeking a fabrication partner with demonstrable expertise.

The ‘Why’ Before the ‘How’: Understanding Stainless Steel’s Personality

Before beginning any manufacturing welding, a true professional understands the unique metallurgical properties of the material. Stainless steel’s behavior under the intense heat of welding is fundamentally different from that of carbon steel.

Mastering stainless steel welding begins not with the torch, but with an appreciation for the material science that governs its every reaction. This foundational knowledge allows fabricators to anticipate challenges before they appear, ensuring consistently high-quality results.

The Secret Armor: The Chromium Oxide Passive Layer

The defining characteristic of stainless steel is its ability to protect itself. This property comes from its key alloying element, chromium, which must be present at a minimum of 10.5% by mass.

When exposed to oxygen, the chromium on the steel’s surface forms a passive, non-reactive, and invisible layer of chromium oxide (Cr₂O₃). This “secret armor” is incredibly thin yet dense and stable.

This passive film acts as a formidable shield against rust. The entire discipline of professional stainless steel welding revolves around creating a mechanically sound joint while meticulously preserving or restoring this essential layer through proper welding practices and post-weld treatments.

A Welder’s Cheat Sheet to the Four Stainless Families

Stainless steels are not a single material but a diverse group of alloys. Each family’s distinct properties directly influence the welding assembly strategy and predict fabrication challenges.

- The Workhorse (Austenitic 300-Series): The most common family (e.g., 304, 316), austenitic grades are non-magnetic, highly ductile, and have exceptional toughness. They are considered the most “weld-friendly” as they are not hardenable by heat treatment and generally do not require preheating. Their primary challenge is distortion control due to high thermal expansion. This makes TIG welding stainless steel 304 and 316 a preferred method in sanitary and precision applications.

- The Brittle Beauty (Ferritic 400-Series): A cost-effective, magnetic alternative with little to no nickel. Their weldability is generally poor in thicker sections (>6 mm) due to rapid grain growth in the heat-affected zone (HAZ), which reduces toughness and increases brittleness post-welding.

- The Knife’s Edge (Martensitic 400-Series): With higher carbon content, these grades (e.g., 410, 420) are extremely hard and strong but difficult to weld. The welding cycle creates a brittle martensitic structure in the HAZ, making them highly susceptible to hydrogen-induced cracking. A disciplined approach with preheating and post-weld heat treatment (PWHT) is mandatory for structural reliability.

- The High-Performer (Duplex): A modern class of alloys with a mixed 50/50 austenite-ferrite microstructure. They combine the high strength of ferritic grades with the excellent corrosion resistance of austenitic grades. Weldability is good, but requires precise heat input control to maintain the critical phase balance, avoiding embrittlement or phase loss.

If your project requires welding duplex stainless frames or mixed-alloy structural assemblies, consult your welding engineer before finalizing the WPS.

The Welder’s Playbook: Conquering the 4 Biggest Stainless Steel Headaches

These common stainless steel welding problems are predictable consequences of the material’s physics. Understanding them is the first step to prevention, turning potential defects into a demonstration of process control and engineering competence.

Headache #1: The War on Warping (Distortion)

Distortion is the most visible challenge, especially with thin-gauge material. It’s a direct result of two conflicting physical properties: low thermal conductivity and a high coefficient of thermal expansion.

Heat concentrates intensely in the weld zone and causes extreme expansion. As the weld cools and contracts, this movement resolves itself as warping, which can lead to significant fit-up issues in the final welding assembly.

An actionable checklist for distortion control includes:

- Lower Amperage: Use 10–15% less amperage than for carbon steel.

- Faster Travel Speeds: A brisk, steady pace prevents excessive heat buildup.

- Stringer Beads: Prioritize straight, narrow beads over wide weaving motions.

- Robust Tacking & Clamping: Use strong fixtures and frequent tack welds to restrain the workpiece.

- Heat Sinks: Clamp copper or brass bars near the weld to actively pull heat away.

For best results, apply these distortion control techniques during fabrication of sheet metal display racks or stainless signage frames. Learn more about metal display rack fabrication.

Headache #2: Decoding the Heat Tint Rainbow

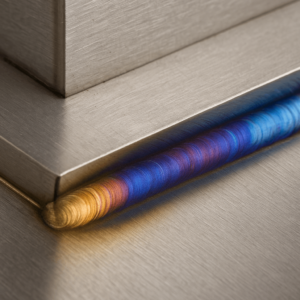

The rainbow of colors in the HAZ after welding is known as heat tint. This is not a harmless discoloration; it is a visible indicator of surface oxidation and a compromised “shield.”

The formation of this thick oxide layer consumes chromium from the steel’s surface, leaving a chromium-depleted zone beneath that is highly susceptible to corrosion. For critical applications, industry standards mandate the complete removal of all visible heat tint. This step is vital for restoring full corrosion resistance.

Buyer Note: In applications like food-grade equipment or vending machine stainless components, heat tint removal is mandatory to maintain hygiene standards.

Actionable Heat Tint Chart

| Heat Tint Color Approx. Temp (°C) Impact on Corrosion Resistance | ||

|---|---|---|

| Light Straw / Pale Yellow | 290–340 | Negligible impact in most environments. |

| Brown / Purple | 390–450 | Reduced corrosion resistance; rework recommended. |

| Dark Blue / Grey / Black | 540–600+ | Significant chromium depletion; must be removed. |

Headache #3: The Invisible Threats: Weld Decay & Cracking

Beyond visible defects, two insidious metallurgical problems can compromise a weld that appears visually perfect.

Weld Decay (Sensitization)

This occurs when austenitic stainless steels are held within a critical temperature range (800°F to 1600°F). In this range, chromium and carbon combine to form chromium carbides at the grain boundaries.

This depletes the surrounding area of the chromium needed for corrosion protection, leading to intergranular corrosion. The primary defense is using low-carbon “L” grades (e.g., 304L, 316L), which contain insufficient carbon for significant carbide formation during a typical weld cycle. These grades drastically reduce the sensitization risk.

Cracking Demystified (Hot vs. Cold)

Cracking in welding is a severe defect. The two main types have different causes and solutions.

- Hot Cracking (Solidification Cracking): Occurs at high temperatures as the weld solidifies. Impurities like sulfur and phosphorus concentrate in the last pockets of liquid, creating weak points that tear apart under shrinkage stress. The solution is to select a filler metal that promotes a small amount of delta ferrite in the weld, which helps dissolve these impurities and resist cracking.

- Cold Cracking (Hydrogen-Induced Cracking): This delayed defect is the primary concern when welding martensitic stainless steels. It requires three factors: a hard, brittle microstructure, tensile stress, and diffusible hydrogen. Prevention involves eliminating one of these factors through preheating, PWHT, and strict adherence to low-hydrogen practices.

Headache #4: Post-Weld Cleanup Isn’t Cosmetic—It’s Structural

Post-weld finishing is often seen as aesthetic, but in stainless steel welding, it plays a critical role in corrosion protection and durability.

Residues like heat tint, embedded iron particles, or weld spatter provide initiation sites for corrosion, especially in chloride-rich or marine environments. Neglecting this step undermines the performance of even the best weld.

Proven Finishing Methods:

- Mechanical Grinding & Flap Discs: Effective for smoothing and blending, especially in visible applications.

- Pickling Paste or Gel: Uses nitric-hydrofluoric acid mixtures to remove oxide layers and chromium-depleted zones.

- Electropolishing: For ultra-smooth, passivated surfaces with superior corrosion resistance in sanitary and food-grade applications.

- Passivation (Nitric or Citric Acid): Restores the chromium oxide layer without removing metal.

Quick Tip: If you’re sourcing sanitary welded components for beverage equipment, electropolishing combined with passivation is the industry standard.

Including post-weld treatment in project specifications demonstrates a full understanding of stainless steel’s lifecycle performance.

Choosing the Right Process: TIG vs MIG vs Stick

Each welding process brings its own advantages, limitations, and suitability based on part thickness, joint configuration, production volume, and aesthetics.

| Process | Pros | Cons | Best For |

|---|---|---|---|

| TIG (GTAW) | Ultra-clean, precise, great for thin sheet and small parts | Slow, requires skill | Custom stainless fabrication, sanitary tubing |

| MIG (GMAW) | Fast, semi-automated, good for mid-thickness material | Less control, more spatter | Industrial brackets, enclosures, furniture |

| Stick (SMAW) | Simple, low equipment cost, good for outdoors | Slag removal, less aesthetic | Structural fieldwork, thick sections |

When welding stainless steel 304 or 316, TIG welding remains the industry benchmark for quality-critical joints. However, MIG offers significant productivity advantages in repeat production runs. MIG welding stainless steel brackets for vending machines or control panels is a common industrial use case.

If your assemblies involve cut-to-size stainless sheets, consider reviewing custom sheet metal fabrication processes to align tolerance and weld readiness early in the design phase.

Safety Is Not Optional: Gas, Gloves, and Good Habits

Stainless steel welding presents elevated safety risks due to hexavalent chromium fumes generated during arc welding.

Mandatory Controls:

- Local Exhaust Ventilation (LEV): Capture fume at the source.

- Proper PPE: Respirators (P100 or supplied-air), TIG gloves, flame-resistant jackets.

- Argon Cylinder Handling: Always upright, chained, and valve-protected.

Workplace safety is part of product quality—unhealthy welders don’t produce consistent parts. OEMs and buyers increasingly require welding shops to prove their compliance with OSHA or ISO 45001.

Final Words: A Strategic Process, Not a Simple Join

Welding stainless steel is not merely about melting and fusing metal. It is about precision, metallurgy, heat management, cleanliness, post-treatment, and safety—executed together, with intent.

Fabricators who master this discipline consistently produce stronger, more hygienic, and longer-lasting results. For procurement managers, choosing a supplier with proven stainless steel welding capabilities is not a cost—it’s a risk mitigation strategy.

Looking for a stainless steel fabrication partner who understands TIG welding, passivation, and post-weld QA like second nature?

YISHANG brings 26+ years of OEM/ODM experience across stainless steel display racks, cabinets, frames, and custom stainless welded parts for vending machines, enclosures, and sanitary hardware. Let’s build precision together.