Introduction: Why the EMC Box Deserves Strategic Attention

To industrial sourcing teams, the EMC (Electromagnetic Compatibility) box often looks like a standard enclosure—commonplace, low-risk, and easy to procure. But treating it this way is a costly mistake.

An EMC box isn’t just metal hardware; it’s an electrical shield. When it’s poorly designed or built, it becomes the silent reason behind certification failures, market delays, and unexpected rework.

This guide equips wholesale buyers and sourcing managers with a compliance-first lens for evaluating EMC enclosures—rooted in real engineering logic, not spec-sheet assumptions.

Why Shielding Fails in Real-World Projects

EMC issues rarely stem from visible flaws. Instead, they’re caused by:

- Excess seam resistance due to coated or oxidized joints

- Poor compression of conductive gaskets

- Improper grounding at cable entry points

These aren’t design flaws alone—they’re sourcing oversights.

Hidden Costs of Late-Stage Failures

A failed EMC test at the certification lab doesn’t just affect compliance—it has cascading effects:

- Launch Delays: Products miss delivery windows

- Retesting Costs: Unbudgeted engineering and lab fees

- Inventory Risks: Held shipments pending recertification

The solution is to treat EMC as a sourcing priority—not an engineering afterthought.

What to Ask During Vendor Evaluation

Go beyond labels like “EMC-compliant.” Ask for evidence:

- Measured attenuation: e.g., 60–80 dB at 100 MHz–1 GHz

- Seam bonding data: <5 mΩ across all joints

- Grounding illustrations: With real 3D drawings and shielding maps

B2B buyers who ask for these move from speculators to decision enablers.

Thinking in Systems: The Enclosure Is Part of the Circuit

Engineering-Centric RFQs Win

Most RFQs list thickness, paint color, and IP rating—but ignore what truly matters:

- Seam bonding continuity: Require <5 mΩ post-assembly

- Compression metrics: ±10% tolerance for EMI gasket under load

- Model files: Request native 3D CAD with bond paths marked

These requirements filter for vendors who engineer for shielding.

Define Compliance Goals, Not Just Specs

If your team only asks for “stainless steel, IP65, hinged door”—you’re missing:

- Bonding of floating panels or door frames

- Material contact resistance post-passivation

- Grounding topology: single-point or mesh grounding?

Your RFQ is your control tool—use it to drive real compliance.

3 Most Overlooked EMC Weak Points in Enclosure Builds

Seam Bonding Failures

- Unmasked coatings increase joint resistance

- Passive stainless forms oxide layers

- Inconsistent fastener torque reduces compression

How to Prevent:

- Specify masked screw holes and bonding pads

- Require resistance testing with <5 mΩ threshold

- Audit surface prep and coating sequence during builds

Cable Entry Leakage

Improper cable gland grounding is a top failure point:

- Use glands with full 360° shield contact

- Avoid plastic glands unless isolated

- Ensure door frames have braided ground straps

Poor Grounding Architecture

Without a grounding diagram, designs risk floating panels, EMI coupling, or intermittent contact.

Best Practices:

- Request grounding schematics

- Ask for labeled continuity test points

- Ensure bonding of all modular sections

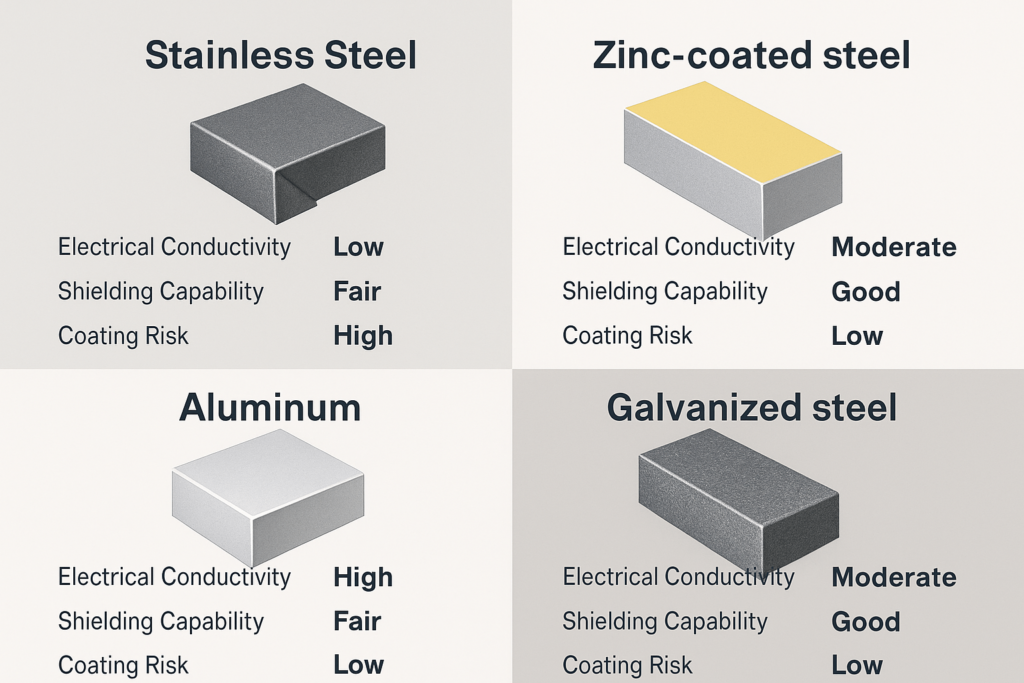

Materials & Coatings That Quietly Kill Compliance

Material and finish directly impact shielding performance.

| Material | Conductivity | Shielding | Coating Risk |

|---|---|---|---|

| Aluminum | Excellent | High | Insulative coatings unless masked |

| Stainless Steel 304 | Moderate | Medium | Post-passivation increases resistance |

| Galvanized Steel | Good | High | Risk of oxidation beneath bond pads |

Procurement Tips:

- Ask for pre/post-coating resistance reports

- Define masking zones in technical drawings

- Select conductive coatings or plating near bonding areas

Shielding isn’t just about design—it’s about material behavior post-processing.

Design for Compliance, Not for Retrofitting

High-functioning suppliers like YISHANG design compliance into the build process—not as a test-time fix.

Benchmarks from our workflow:

- Resistance <3 mΩ before coating and <5 mΩ after

- Real-time gasket compression logging during final assembly

- Visual masking of bonding points before powder coating

Whether you partner with YISHANG or not, use this as your vendor audit baseline.

EMC-Ready Procurement Checklist

Use this checklist before approving prototypes or POs:

| Category | What to Confirm |

|---|---|

| Gasket Compression | ±10% within design spec under load |

| Seam Bonding | <5 mΩ across mating surfaces |

| Cable Gland Grounding | Full 360° contact with metal surface |

| Coating Masking | Verified masking zones on drawings and samples |

| Grounding Topology | Diagrammed, with inspection/test points marked |

Buyers who follow this checklist lower rejection rates—and certification time.

Reframing the EMC Box as a Strategic Sourcing Lever

Treating EMC enclosures as low-cost metal boxes is outdated. Strategic buyers know:

- The cost of failure is higher than cost per unit

- Cert-ready enclosures save months of retesting

- Verified technical specs de-risk compliance bottlenecks

At YISHANG, we help B2B buyers avoid delays with:

- CAD-based enclosure simulations for bonding

- Custom box fabrication with cert-ready grounding

- EMC validation workflows tailored to global markets

Have a project at risk of delay? Let’s connect.