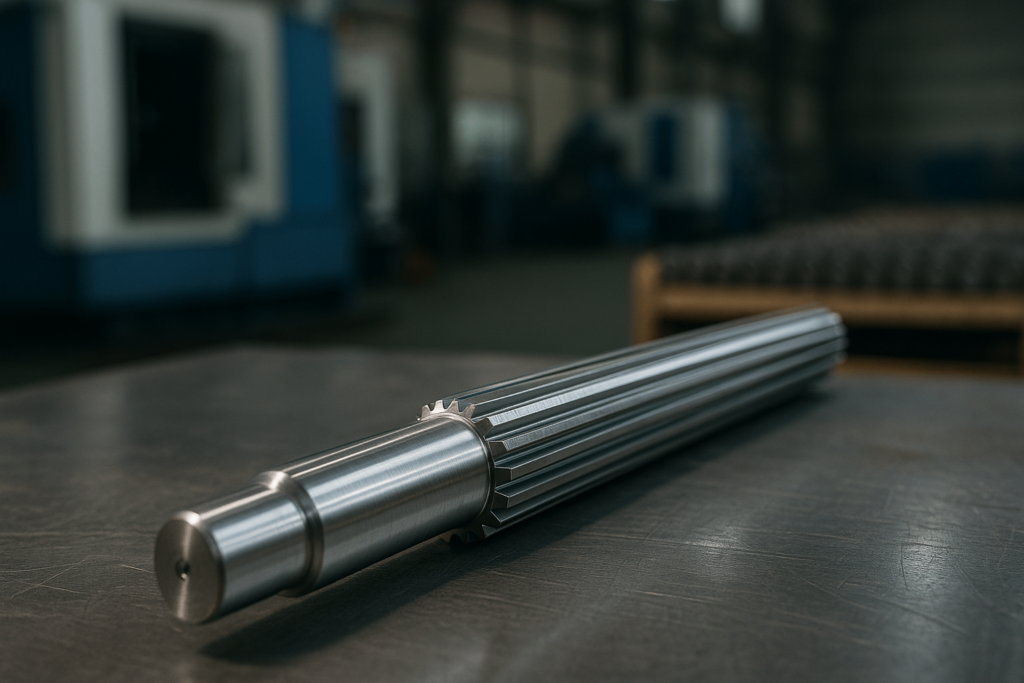

In the global supply chain of mechanical components, the selection of a part like a shaft can have profound consequences on product performance, brand reputation, and long-term profitability. For years, the keyed shaft was a familiar, low-cost option. However, as performance demands have escalated, the design flaws of the keyway have become a significant liability. The modern engineering solution is the splined shaft, a component designed for superior strength and reliability.

This guide is written for procurement managers, sourcing specialists, and engineers who make critical component decisions. It moves beyond basic definitions to provide a strategic framework for understanding spline technology. We will analyze the failures of keyed connections, offer a decision-making guide for spline profiles, and reveal how manufacturing processes directly impact a component’s strength and value. It offers actionable criteria for failure-proof component sourcing, where performance and risk mitigation converge.

The Keyway’s Fatal Flaw: Why the Engineering World Moved to Splines

The industry-wide shift from keyed to splined shafts was an engineering imperative, driven by the physics of stress and the financial risks of component failure. The simplicity of the keyed shaft is deceptive, as its design harbors weaknesses that are unacceptable in modern machinery. For a buyer, understanding these flaws is crucial to appreciating the value and risk-mitigation offered by a well-made spline.

The Inherent Risks of Keyed Connections: Stress Concentration and Imbalance

A keyed connection relies on a slot (the keyway) cut into both the shaft and the mating hub, with a separate metal key locking them together. This design introduces two fundamental risks that directly impact product longevity.

First is the critical issue of keyway stress concentration. The sharp corners at the base of a keyway are natural stress risers. Under load, all torque is transmitted through these points. In applications with cyclic loads, these corners become the inevitable origin points for fatigue cracks, leading to catastrophic failure. For a product line, this translates to unpredictable field failures and costly warranty claims.

Second is the problem of shaft imbalance. Machining a keyway removes material asymmetrically, creating an imbalance that causes vibration at high speeds. This vibration not only generates noise but also accelerates wear on bearings and other critical components, shortening the service life of the entire assembly.

The Spline as the Engineered Solution: A Revolution in Load Distribution

The splined shaft is the definitive engineering solution to these problems. By integrating multiple teeth, or splines, directly into the shaft‘s geometry, the connection becomes a single, robust component. These teeth engage with corresponding grooves in the hub, distributing the load across the shaft’s entire circumference.

This design provides a revolutionary advantage in load distribution. Instead of concentrating force on a single point, a spline connection shares the load across numerous teeth, eliminating the dangerous stress risers. This dramatically improves fatigue resistance. Furthermore, the symmetrical design creates an inherently balanced component, essential for the smooth, high-RPM operation required by modern machinery.

The Performance Data: A Decisive Difference in Torque Capacity

The engineering theory is unequivocally supported by performance data. Both analysis and physical testing confirm that a splined shaft can transmit approximately 30% more torque than a keyed shaft of the same diameter and material.

This is a critical metric for procurement. This superior spline shaft torque capacity allows designers to create more compact and lightweight systems. For a buyer, this means sourcing a component that offers a higher performance ceiling and a greater margin of safety, directly contributing to the quality of the final product.

A Strategic Selection Guide: Matching the Spline Profile to the Engineering Challenge

Specifying a “splined shaft” is only the beginning. The real sourcing challenge lies in selecting the optimal profile. Each of the primary types of splined shafts is a specialized solution, and understanding their advantages is key to avoiding over-engineering (cost) or under-engineering (failure).

The Workhorse (Involute Spline): For High Torque and Precision

The involute spline is the most prevalent profile in high-performance applications, from automotive transmissions to aerospace gearboxes. Its teeth feature a curved, involute geometry—the same profile used in high-strength gears—which provides superior strength by reducing stress concentration at the tooth root.

A key advantage for reliability is its self-centering capability. When torque is applied, the tooth geometry generates a radial force that automatically aligns the shaft within the hub, minimizing vibration and ensuring the load is shared evenly.

Procurement Insight: For any high-torque or high-speed application, the involute spline is the default choice for ensuring reliability. Its widespread adoption means it is governed by well-established international standards (ISO, ANSI, DIN), simplifying global sourcing and ensuring interoperability.

The Misalignment Specialist (Crowned Spline): For Systems with Inherent Flex

No mechanical system is perfectly rigid. Structural flex and thermal expansion can introduce angular misalignment. While a standard spline can only tolerate less than 1 degree of misalignment, a crowned spline is specifically engineered to solve this problem. The teeth are subtly “crowned,” making them thickest at the center and tapering toward the ends.

This unique geometry allows the shaft to pivot, safely accommodating angular misalignments of up to 5 degrees.

Procurement Insight: Specifying a crowned spline is a critical risk-mitigation strategy for applications like automotive drive shafts or long industrial shafts. It prevents severe point-loading and premature wear, directly extending the service life of the final product.

The Precision Grip (Serrated Spline): For Control and Anti-Slip Performance

In applications like instrumentation or military hardware, precise positioning and a zero-slip connection are often more critical than raw torque capacity. The serrated spline excels here. Its “V”-shaped teeth allow for a high number of contact points on a small-diameter shaft, creating an exceptionally secure, self-centering grip.

Procurement Insight: For products requiring high-fidelity control and absolute rotational accuracy, the serrated spline provides the necessary performance. Its design is particularly effective for ensuring that control knobs and actuators maintain their precise orientation. Learn how similar configurations are applied in CNC Machined Aluminum Parts.

The Smooth Operator (Helical Spline): For Quiet Power and Linear Motion

A helical spline features teeth that are angled in a helix pattern. This design causes the teeth to engage gradually, resulting in significantly smoother, quieter power transmission. This is a key advantage in premium applications where noise, vibration, and harshness (NVH) are critical quality factors.

Furthermore, helical splines can be designed to translate rotary motion into linear motion, a vital function in advanced systems like aerospace actuators and telescoping shafts.

Procurement Insight: For high-end machinery where operational smoothness is a key selling point, specifying helical splines can provide a distinct competitive advantage.

The Hidden Strength Multiplier: Why Manufacturing Process is as Critical as Material Choice

For a procurement manager sourcing critical metal components, understanding the nuances of manufacturing is paramount. While spline shaft material selection is a vital first step, the manufacturing process has a profound impact on the part’s final strength and durability. This is where a supplier’s deep, practical experience becomes a crucial asset.

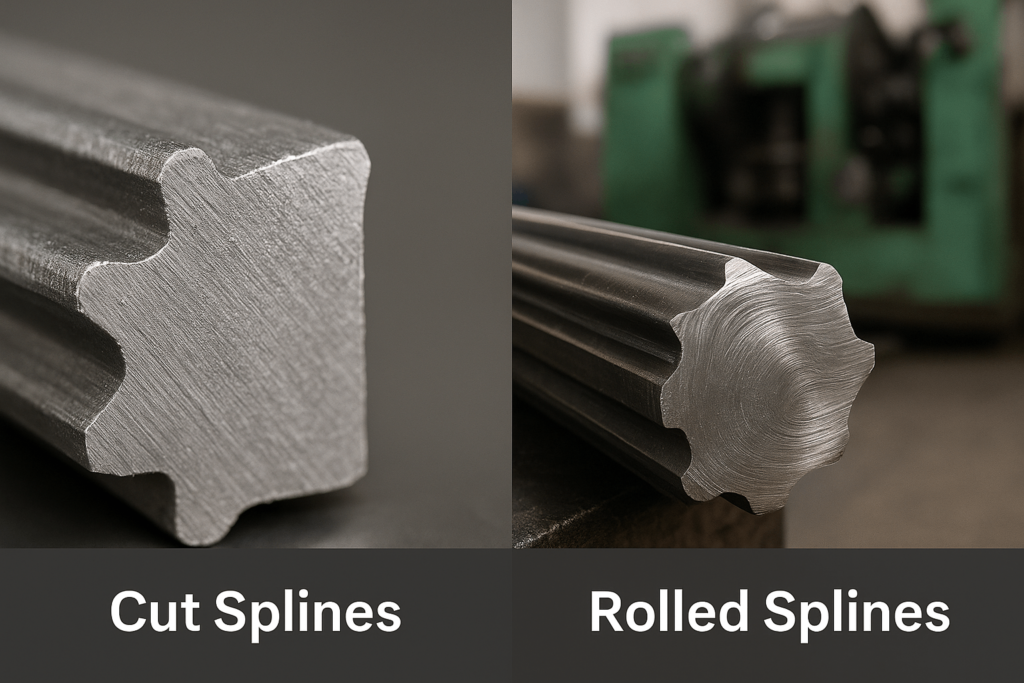

The Great Divide: Cut vs. Rolled Splines—A Critical Decision

There are two fundamentally different ways to create splines: cutting the metal away or rolling it into shape. The choice directly affects the component’s fatigue life.

Cut Splines (Hobbing/Milling): These traditional subtractive processes use a cutting tool to remove material. While effective for creating precise geometries, cutting severs the natural grain structure of the metal. This is analogous to cutting across the grain of wood—it creates inherent weak points at the tooth root, where fatigue cracks are most likely to initiate.

Rolled Splines (Cold Forming): Spline rolling is a formative process. Instead of cutting, hardened dies apply immense pressure (often 50,000 psi or more) to displace the metal and form the teeth. This process does not break the material’s grain structure. Instead, it forces the grain to flow along the contour of the tooth. This provides two immense benefits: a continuous grain flow for superior strength, and “work hardening,” which increases surface hardness and creates compressive residual stresses that fight against fatigue. The result is a spline that is up to 35% stronger and significantly more fatigue-resistant than a cut spline of the same material.

The Trade-Off Analysis for Procurement

| Manufacturing ProcessStrength & Fatigue LifeTooling CostIdeal Sourcing Application | |||

|---|---|---|---|

| Spline Rolling (Cold Forming) | Superior (up to 35% stronger) | High | High-volume production; mission-critical applications (automotive, aerospace); parts where field failure is unacceptable. |

| Spline Cutting (Hobbing/Milling) | Good | Low to Moderate | Prototyping; low-volume runs; less critical applications where the absolute highest fatigue life is not required. |

Procurement Insight: For high-volume or high-reliability products, the higher initial tooling cost for spline rolling is a wise investment. It translates directly to a more robust product with a lower risk of field failures, reducing the total cost of ownership and protecting brand reputation.

Material Decision Matrix: A Sourcing Guide

The final piece of the puzzle is matching the material to the application’s demands. A knowledgeable supplier can guide this decision to ensure optimal performance without unnecessary cost.

| Material (Example Grade) Key Strengths Key Procurement Consideration | ||

|---|---|---|

| Carbon Steel (45 Steel) | Excellent balance of strength, toughness, and cost. | The best value choice for general-purpose and moderate-load applications where cost-effectiveness is a primary driver. |

| Alloy Steel (40Cr, 35CrMo) | High tensile strength, superior toughness, and fatigue resistance. | The standard for heavy-duty, high-torque, or impact-load applications. The higher material cost is justified by performance. |

| Nitriding Steel (38CrMoAlA) | Extreme surface hardness and wear resistance with minimal distortion. | A premium choice for high-precision applications where surface durability and dimensional stability after heat treatment are critical. |

| Stainless Steel | Superior corrosion resistance. | Essential for applications in corrosive environments (marine, food processing). Ensures product longevity where standard steels would fail. |

Mitigating Risk: A Practical Guide to Diagnosing and Preventing Spline Shaft Failure

For a wholesale buyer, a component failure is a business problem that can lead to costly recalls and damage your brand’s reputation. Understanding the common causes of spline shaft failure is essential for mitigating this risk. A truly expert manufacturing partner doesn’t just make parts; they understand systemic contributors to failure and can help you prevent them.

Reading the Fracture Surface: How to Diagnose Fatigue vs. Overload Failures

When a shaft fails in the field, the broken piece contains vital information. Learning to distinguish between the two primary failure modes provides clues to the root cause.

Fatigue Failure: This is the most common failure mode, caused by repeated cyclic loading. The fracture surface of a fatigue failure often shows distinct “beachmarks”—fine, concentric lines that show the slow, progressive growth of a crack from an initiation point. This indicates that the component was failing over time, not from a single event.

Overload Failure: This is a sudden, catastrophic failure caused by a single load event that exceeds the material’s strength. In a ductile steel shaft, this often involves visible twisting or plastic deformation. A brittle overload fracture may show V-shaped “chevron marks” that point back to the fracture’s origin.

The Prevention Playbook: The Science of Lubrication, Fit, and Alignment

The vast majority of spline failures are not due to defective material but to preventable system-level issues. Ensuring these three factors are correctly specified and controlled is the key to reliability.

- Lubrication is Non-Negotiable: A spline connection requires a film of high-load grease to function reliably. Without it, the microscopic movements between the teeth cause fretting corrosion (visible as a reddish-brown powder) and galling, which create surface damage that can initiate fatigue cracks. Sourcing Implication: Ensure that the end-product’s assembly and maintenance guidelines clearly specify the lubrication requirements for the splined components you supply.

- Master the Fit (The Importance of Standards): The clearance between mating splines is a critical design parameter. Too much clearance (backlash) causes impact loading, while too little can prevent lubrication. This is why international standards are so important. Specifying a fit like ANSI B92.1 Class 5 or adhering to ISO 4156 and DIN 5480 ensures that parts will mate correctly and perform as expected. Sourcing Implication: Always specify compliance with a recognized international standard. This is your primary tool for ensuring quality and interoperability in a global supply chain.

- Hunt Down Misalignment: Misalignment is the “silent killer” of splined shafts. Even a small offset forces a few teeth to carry the entire load, leading to rapid failure. While crowned splines can accommodate this, precise initial alignment using tools like laser alignment systems is always the best practice. Sourcing Implication: Partnering with a manufacturer who maintains tight concentricity and dimensional tolerances is your first line of defense against misalignment-related failures.

The Future of Torque: Smart Shafts, Advanced Composites, and Additive Manufacturing

The technology of torque transmission is continuously advancing, driven by the demands for greater efficiency and lighter weight in modern machinery. For forward-thinking procurement teams, understanding these trends is key to sourcing components that will provide a competitive edge.

The Rise of Additive Manufacturing (3D Printing)

Additive manufacturing is evolving beyond prototyping into a viable process for low-volume, high-complexity metal parts. Technologies like wire-laser metal deposition can now produce a 3D printed splined shaft that is near-net-shape, dramatically reducing material waste and machining time. This opens the door for highly optimized, lightweight designs that are impossible to produce with traditional methods.

The Shift to Advanced Materials

In weight-critical industries like aerospace and electric vehicles, the focus is shifting from steel to advanced materials. Composite splined shafts, made from carbon fiber, offer an incredible strength-to-weight ratio. For extreme temperature or chemical environments, high-performance polymers like PEKK are replacing metal, offering new levels of performance.

The “Smart Shaft” Revolution

The most transformative trend is the integration of intelligence. The “Smart Shaft” concept involves embedding sensors directly into the shaft to provide real-time data on torque and vibration. This enables predictive maintenance, allowing systems to report that they need service before a failure occurs. Business Implication: For manufacturers and their clients, this technology represents a monumental shift from scheduled to condition-based maintenance, promising to drastically reduce downtime and lower lifecycle costs.

Conclusion: Sourcing More Than a Part—Sourcing Expertise

From its clear superiority over the flawed keyway to its future as an intelligent component, the splined shaft is a cornerstone of modern mechanical design. However, this guide has shown that sourcing a high-performance spline is about more than just a technical drawing.

True reliability and value are born from a deep understanding of the entire engineering ecosystem: matching the right profile to the application’s challenges; leveraging the hidden strength multiplier of advanced manufacturing processes like cold rolling; and implementing a rigorous, science-based approach to failure prevention.

This is precisely where the expertise of a specialist manufacturer like YISHANG, with deep roots in forming and machining high-precision splines for 26+ years, provides its greatest value—transforming an optimal design on paper into an engineered masterpiece of strength and reliability.

If you are looking for a partner with deep expertise in spline manufacturing, send your inquiry today.

Frequently Asked Questions (FAQ)

What is the advantage of a cold rolled spline shaft over a cut spline?

Cold rolled spline shafts offer up to 35% greater fatigue strength compared to cut splines due to uninterrupted grain flow and compressive surface stresses. This makes them ideal for mission-critical applications where longevity and shock resistance are essential.

Which spline profile is best for high torque applications?

The involute spline is the best-suited for high torque transmission. Its curved tooth profile minimizes stress concentrations and offers superior load distribution, making it ideal for automotive and aerospace drivetrain systems.

Can I source custom spline shafts in China with specific standards like ANSI B92.1 or DIN 5480?

Yes. Many Chinese manufacturers like YISHANG offer full custom spline shaft manufacturing with strict adherence to standards such as ANSI B92.1, ISO 4156, or DIN 5480. This ensures compatibility and performance for international equipment.

How can I avoid fatigue failure in a spline shaft?

To prevent fatigue failure, ensure proper lubrication, accurate alignment, and compliance with fit tolerances. Cold forming the splines and specifying proper materials like 40Cr or nitriding steels also significantly boost resistance to fatigue cracking.

Are helical splines suitable for converting rotary to linear motion?

Absolutely. Helical spline shafts are engineered for smooth torque transfer and axial movement. They’re commonly used in linear actuators and telescoping assemblies that demand quiet operation and controlled extension.