Introduction

Titanium alloys have become indispensable in industries where high performance meets demanding environments. For global procurement specialists sourcing reliable suppliers, titanium is not only about strength or resistance—it’s about trusted delivery, certifications, machining capability, and application-specific consulting.

At YISHANG, we offer more than material—we offer a complete titanium solution. Backed by 26+ years of precision manufacturing experience and exports to over 50 countries, we specialize in CNC machining, sheet metal forming, anodizing titanium, and OEM/ODM service tailored for high-demand industries. This guide unpacks how titanium alloys can fit into your procurement strategy with maximum efficiency and technical confidence.

Why Titanium Alloy? — Value-Driven Decisions in Industrial Sourcing

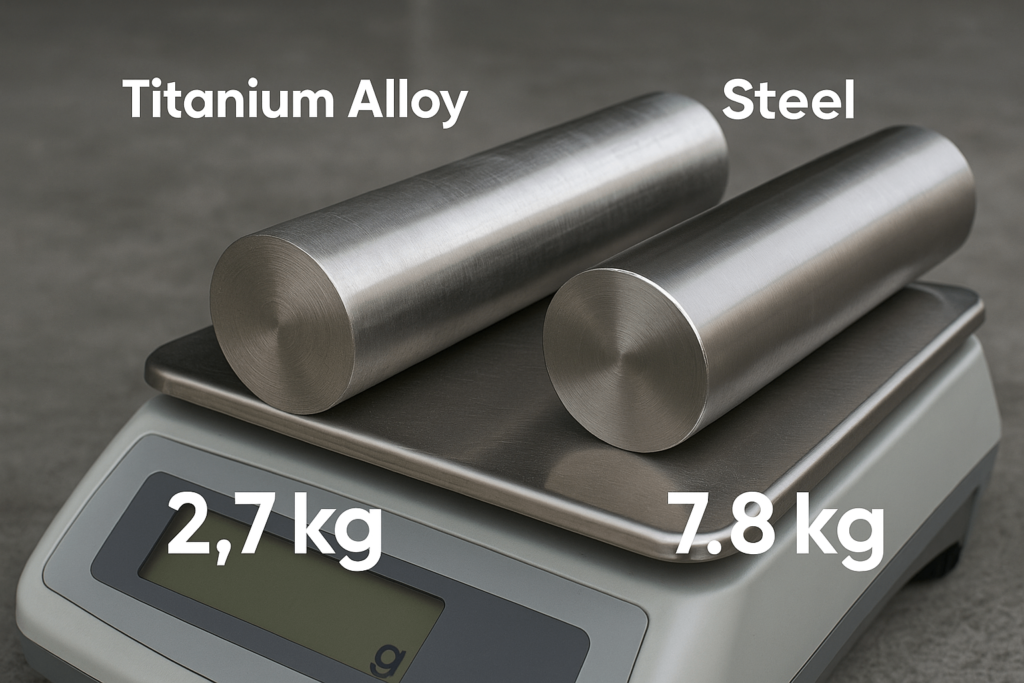

Titanium’s most cited feature is its strength-to-weight ratio—nearly 45% lighter than steel yet comparable in tensile strength. For applications like aerospace, energy, or EV battery structures, this translates to significant payload and fuel efficiency gains.

However, what makes titanium a preferred material for procurement isn’t just technical—it’s lifecycle economics. Benefits of titanium include longer service life, reduced maintenance, and lower long-term cost of ownership. Its natural oxide layer makes it corrosion-resistant even in saltwater and acidic environments.

For wholesale buyers, selecting titanium means reducing warranty claims, avoiding repaint cycles, and meeting performance specs. Grades 2 and 11, for instance, are highly sought for marine systems thanks to proven chloride resistance.

Understanding Titanium Alloys — What Your Supplier Should Know

Not all titanium alloys are suitable for every project. Their differences matter—especially when you’re buying in bulk for high-risk sectors like medical, chemical, or defense.

Titanium can be classified into alpha, beta, and alpha-beta alloys. Alpha types are ideal for cryogenic and oxidizing environments. Beta alloys, strengthened by molybdenum and vanadium, offer excellent formability and are heat-treatable. The most commonly requested by our clients is Grade 5 (Ti-6Al-4V)—an alpha-beta alloy delivering strength and corrosion resistance.

Understanding whether to choose aluminium or titanium, or use an aluminium and titanium alloy hybrid, requires guidance. YISHANG provides alloy mapping support based on stress loads, environment, budget, and required standards such as ASTM B348 or ISO 5832.

Titanium Alloy Properties — What Procurement Teams Need to Evaluate

Strength and Weight Advantage

Titanium alloys offer tensile strengths from 600 to 1200 MPa. Combined with low density (4.51 g/cm³), they significantly outperform most metals on strength-to-weight, especially when comparing steel vs titanium weight in structural or aerospace projects.

Corrosion Resistance

Titanium is non-reactive in chloride-rich and acidic environments. Alloys such as Grade 7 and 11 contain palladium for added durability. This is why we frequently supply titanium parts for offshore desalination units and chemical reactors.

Biocompatibility and Compliance

Titanium Grades 2, 5, and 23 are certified under ASTM F67/F136 and used in implants globally. Their compatibility with living tissue, combined with MRI safety, makes them the preferred choice in medical procurement.

Thermal Considerations

Though not ideal for heat dissipation (thermal conductivity ~21 W/m·K), titanium maintains mechanical stability up to 400–600°C, ideal for aerospace and turbine environments. This makes it superior in settings where aluminum may soften under stress.

Titanium Alloy Grades — Practical Comparison for Buyers

| Grade | Composition | Features | Best Use Cases |

|---|---|---|---|

| Grade 1 | Pure | Soft, highly ductile | Heat exchangers, ductwork |

| Grade 2 | CP Titanium | Weldable, corrosion-resistant | Piping, medical trays |

| Grade 5 | Ti-6Al-4V | Strongest, versatile | Aerospace, orthopedic devices |

| Grade 7 | CP + Pd | Acid-resistant | Tanks, reactors |

| Grade 11 | CP + Pd | Marine-ready, weldable | Subsea, desalination |

| Grade 12 | Ti-Ni-Mo | Formable, pressure-resilient | Heat exchangers |

| Grade 23 | Ti-6Al-4V ELI | Low oxygen, high purity | Bone screws, surgical tools |

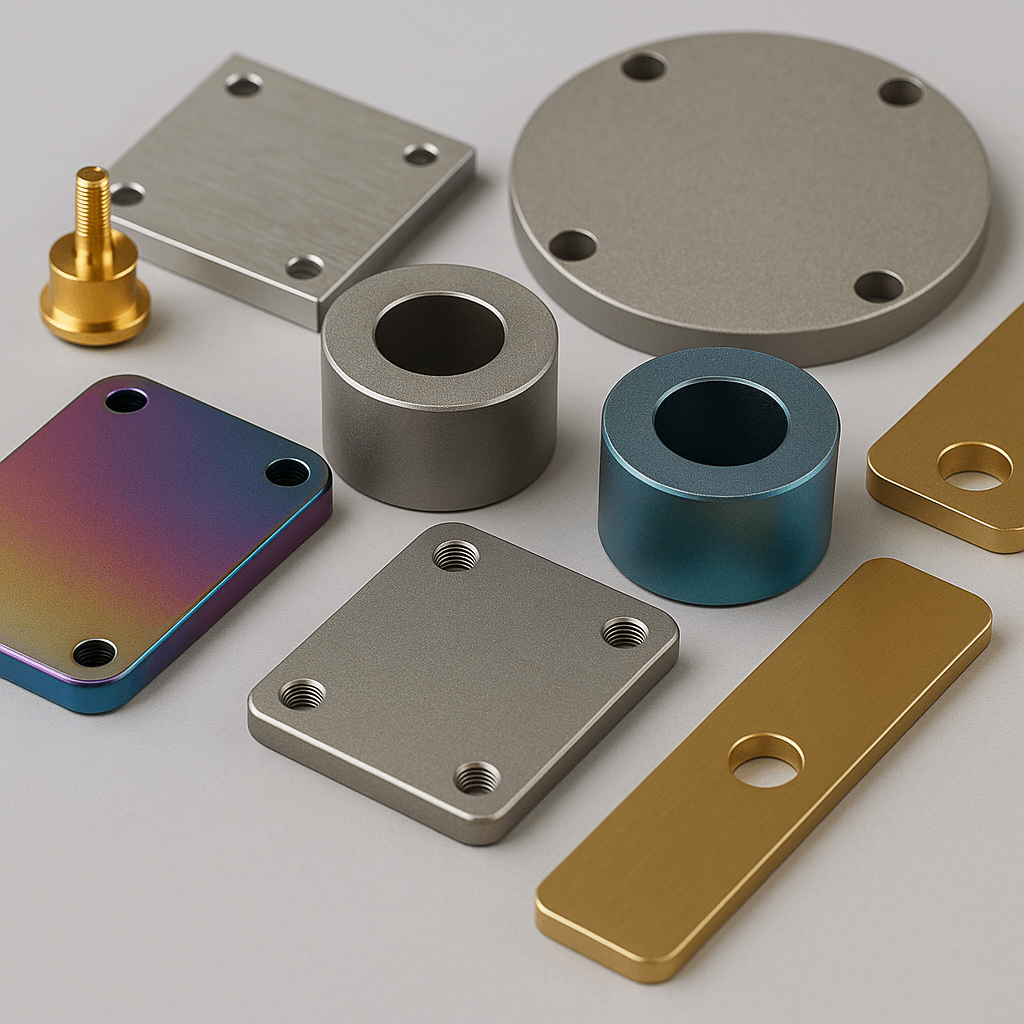

Choosing a grade isn’t just technical—it impacts pricing, formability, lead time, and compliance. At YISHANG, we offer buyers side-by-side grade comparisons and can assist with mill test reports, RoHS documents, and custom finishing like anodized titanium colors based on brand or function.

From RFQ to Shipment — How YISHANG Handles Titanium Production

Precision Machining

Titanium alloys are challenging due to their work-hardening nature and heat retention. We use CNC machines equipped with carbide tooling, precision coolant control, and experienced operators to produce parts with ±0.01 mm accuracy.

Whether for anodized titanium, structural plates, or complex housings, we ensure consistent quality even on large-volume orders.

Forming and Welding

Hot forming is applied to reduce spring-back, especially for bead blast titanium enclosures or bent profiles. We also support anodizing titanium and hydroforming for lighter structural panels or curved elements.

Welding is carried out in argon-purged environments with TIG and laser methods, ensuring strength and ductility without contamination—critical for buyers in chemical or medical sectors.

Surface Treatment & Export Packaging

Buyers increasingly request cosmetic or functional finishes. We offer:

Anodising titanium for enhanced oxide layer protection

Anodizing titanium chart options for color coding

PVD, passivation, bead blasting, and powder coating

Packaging includes foam-insert crates, international labeling, and export-ready documents (CO, MSDS, HS Codes).

Strategic Applications — Where Titanium Delivers Value

Aerospace Systems

Titanium reduces fuel load and increases payload. We supply jet engine parts, frame assemblies, and high-heat mounts in Grade 5 and 9. Our parts are DFARS compliant and meet ISO 9100 production traceability.

Medical Components

From implants to surgical tools, titanium’s biocompatibility reduces rejection and infection risk. We regularly manufacture parts for orthopedic OEMs requiring anodized titanium, polished rods, and forged implants.

Marine and Desalination Systems

Grade 2 and 11 components are resistant to brine, algae, and long-term corrosion. We support projects including water treatment skids, deep-sea drones, and underwater sensors.

Energy and Chemical Plants

YISHANG supplies reactors, baffles, and tubesheets made with Grade 7 and 12 for acid processing and steam cycle durability.

Emerging EV and Battery Tech

Lightweight, corrosion-proof titanium battery enclosures and hydrogen tanks are gaining traction. We provide sheet metal prototypes and validate assembly strategies with EV OEMs.

When Titanium Is Not Ideal — Matching Needs to Materials

As your materials partner, we advise when aluminium titanium hybrids or alternatives may work better.

For low-load structures: 6061 aluminum offers better thermal flow

For conductive needs: Copper or aluminum is preferable

For budget-limited builds: 304/316L steel might suffice

By evaluating design load, operating environment, and volume, YISHANG helps clients avoid overspecifying.

Market Trends — Titanium Sourcing in a Global Context

Titanium is on track for a 6.3% CAGR through 2030. Demand is being fueled by aviation, energy transition, and defense projects.

But geopolitical risks and refining bottlenecks impact supply. That’s why YISHANG sources from stable, certified Chinese mills and maintains strong local machining capacity. With closed-loop recycling and on-site QC, we minimize risk for international buyers.

We support:

Sample orders and pilot runs

Compliance documentation for EU/U.S.

Cost breakdowns by grade, finish, and lead time

Conclusion

Titanium alloy is more than a metal—it’s a strategic material when chosen and processed correctly. With YISHANG, you don’t just get parts; you get supplier reliability, engineering clarity, and faster time to market.

From RFQ to global delivery, we help industrial buyers simplify titanium sourcing.

📩 Let’s talk about your titanium project—just send us your specs or drawings.