Why Brass Melting Temperature Matters for Global Buyers

If you’re sourcing brass products in bulk, “what is the melting point of brass?” is more than a technical trivia—it’s a procurement-critical detail. Brass is not a pure metal but a diverse class of copper-zinc alloys. Each alloy has its own brass melt temp, which impacts casting quality, machining results, and welding performance.

Most melting temperatures of brass alloys fall between 900 °C and 940 °C (1652–1724 °F), but procurement errors often arise from assuming a fixed value. This melting range affects how well components hold shape, resist thermal distortion, or survive downstream operations.

Brass Grades & Their Melting Ranges

For buyers comparing material types, referring to a brass alloy melting point chart can clarify which grades are suitable for specific processes. Brass isn’t a single material—it’s a family of alloys. Its thermal properties depend on copper-zinc ratios and added elements like lead, tin, or aluminum. These variations determine how brass responds to heat and what processes it’s suited for.

For example, C360 Free-Cutting Brass (61.5% Cu, 35.5% Zn, 3% Pb) melts between 875–895 °C, making it a common choice for CNC machining applications where a consistent melting range is crucial. It machines well but isn’t suitable for brazing. C260 Cartridge Brass (~70% Cu) melts at 900–920 °C and is ideal for deep drawing. C464 Naval Brass adds tin to improve corrosion resistance and has a melt range closer to 940 °C.

| Brass Type | Cu/Zn/Other Composition | Melting Range (°C) |

|---|---|---|

| C260 Cartridge | 70/30 | 900–920 |

| C464 Naval | 60/39.25/0.75 Sn | 915–940 |

| C360 Free-Cutting | 61.5/35.5/3 Pb | 875–895 |

Understanding these melting behaviors helps buyers align alloy selection with forming, welding, or thermal processing conditions. For procurement, the melting temperature of brass should always be treated as a range tied to alloy composition.

Microstructure & Alloy Behavior Under Heat

Minor differences in microstructure can lead to major impacts during processing. Leaded brasses, for instance, liquate early under welding heat. This weakens joints and may cause cracking. Aluminum-bearing brasses resist heat penetration, affecting laser-cut edge quality.

At YISHANG, we’ve helped customers avoid thermal distortion in electronics enclosures and kiosks by matching the brass type to the downstream process. It’s not just about choosing an alloy—it’s about choosing it for the right stage of manufacturing.

Thermal Processing in Manufacturing: Real-World Impacts

Brass that melts too early or too unevenly causes defects in casting, welding, and forming. If the furnace temperature exceeds the zinc vapor point (907 °C), porosity and strength loss occur. If it’s too low, molds won’t fill, or welds won’t bond fully.

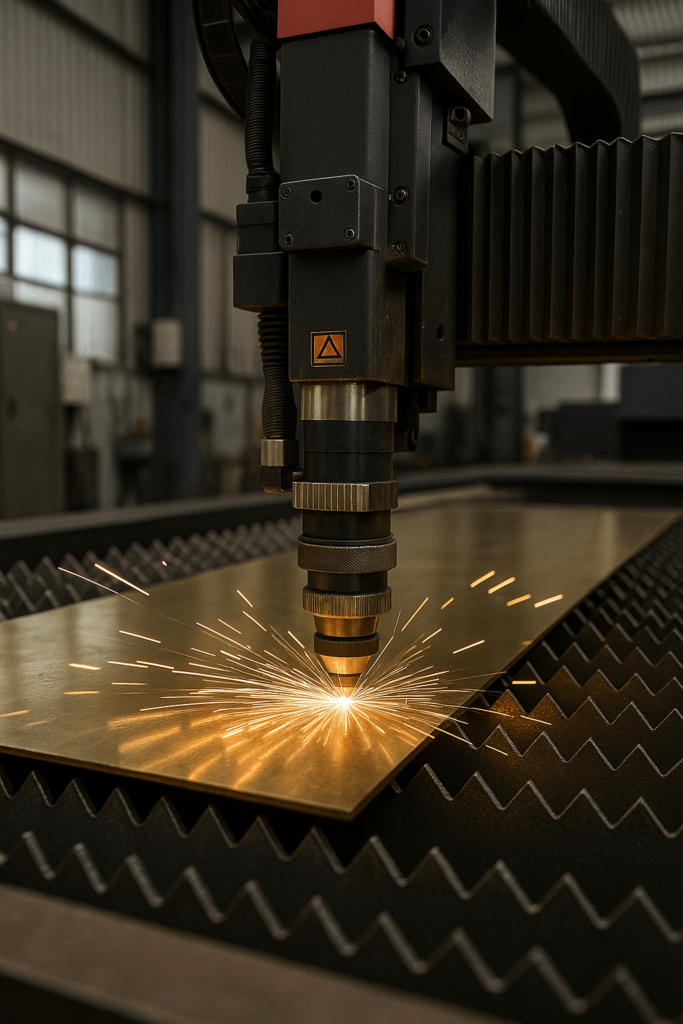

Laser cutting poorly matched brass—especially those with inconsistent melting behavior—results in edge burns or inconsistent cuts. That’s why confirming the exact melting temperature of brass is essential to avoid thermal flaws in production.

Zinc Vapor: A Hidden Safety and Quality Variable

When brass exceeds 907°C, zinc starts to vaporize, releasing zinc oxide fumes. This not only affects health—regulated by OSHA to under 5 mg/m³—but also alters alloy composition and surface quality.

Procurement teams should verify supplier practices around fume extraction, thermal limits, and safe handling procedures. This is especially critical when sourcing recycled brass or specifying repeated melt cycles.

How Suppliers Monitor and Control Brass Melting

Reliable partners don’t guess—they measure. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) provide clear melt range data. Pyrometers and thermal cameras ensure consistency during production.

Buyers should request melt-point traceability certificates in RFQ stages to ensure that thermal performance is aligned with downstream processing expectations.

We ensure ASTM-grade certifications like B16 or B171 accompany each batch, along with batch-specific reports. For procurement, that translates to less trial and error and higher confidence in the materials received.

Matching Alloy to Application: A Procurement Priority

Understanding how to choose brass for high-temp applications is critical when thermal performance is involved. Some alloys handle sustained heat better than others, and mismatched selection can lead to structural or aesthetic failures.

Don’t just ask for “brass.” Ask how it will be used. For example:

Need post-machining stability? Use C360.

Require seawater resistance? Choose C464.

Planning laser cutting or cold forming? C260 performs best.

Procurement teams should verify the melting temperature of brass for the chosen alloy to avoid mismatched selections.

FAQs for Buyers and Engineers

Q: What is the melting point of yellow brass vs red brass?

Yellow brass, typically higher in zinc content, melts between 900–940 °C. Red brass, with more copper, melts slightly higher and offers improved corrosion resistance in some applications.

Q: What is the melting point of brass?

It’s a range—typically 900–940 °C depending on alloy type.

Q: Is the melting temperature of brass fixed?

No. It changes with alloy composition, which is why each brass melt temp must be verified for specific projects.

Final Takeaways for Bulk Brass Procurement

Brass melts in a range—not a point. Always specify alloy. Confirm certifications or DSC data for critical projects. Understand how melt behavior affects joining, machining, and forming.

Procurement teams should also request supplier documentation of the melting temperature of brass to avoid miscommunication and ensure repeatable quality.

YISHANG applies strict melt profiling and monitoring, ensuring every brass melt temp aligns with process requirements. That’s how we help buyers reduce lead times, control costs, and avoid rejects.